Photosensitive resin composition

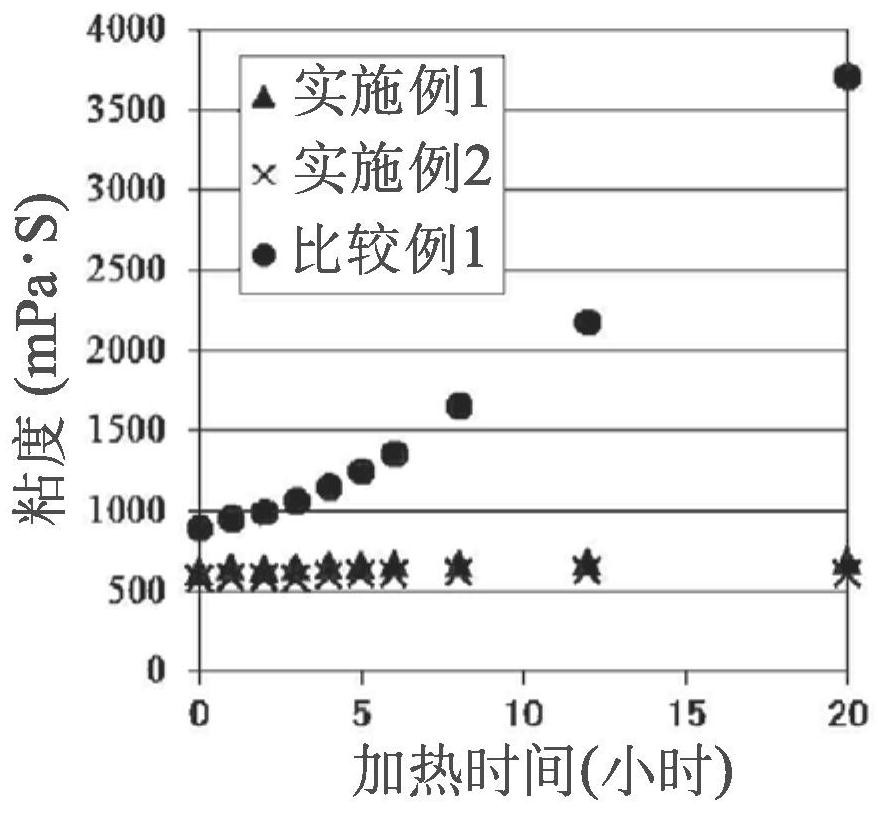

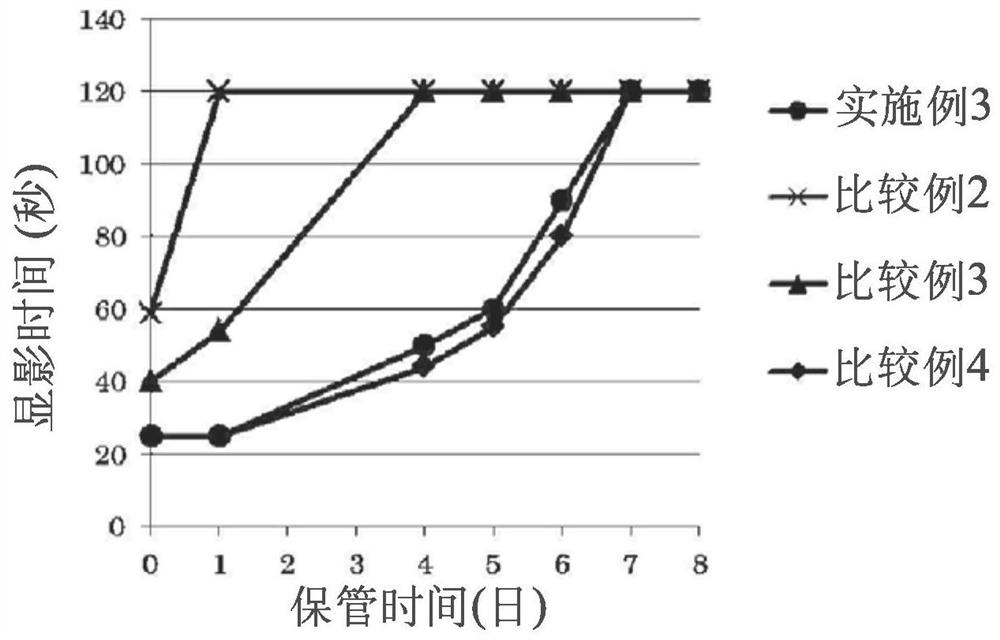

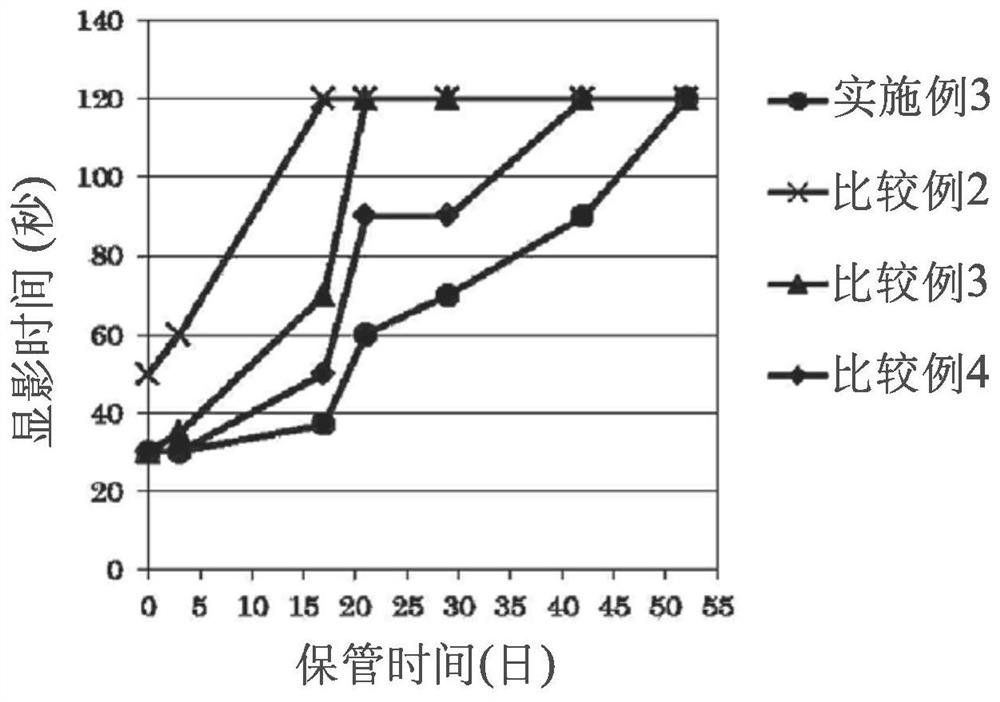

A resin composition and resin technology, applied in the field of photosensitive resin composition, can solve the problems of poor storage stability, unusability, viscosity increase, etc., achieve good storage stability, and suppress the effect of viscosity increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0204] Hereinafter, the present invention will be described in more detail through examples, but the present invention is not limited to the examples. Furthermore, unless otherwise specified, "parts" and "%" herein are based on mass.

Synthetic example 1

[0205] Synthesis Example 1 (Synthesis of Compound Represented by Formula (1) (Component (A-1)))

[0206] According to the description in Example 6 of JP-A-2017-105749, the compound (A-1) represented by the formula (1) was obtained.

[0207]

Synthetic example 2

[0208] Synthesis Example 2 (Synthesis of Compound Represented by Formula (1) (Component (A-2)))

[0209] (step 1) synthesis of the intermediate compound represented by formula (31)

[0210]After adding and dissolving 10 parts of water and 53 parts of ethanol to 1.9 parts of potassium cyanide, the reaction liquid was degassed by ultrasonic treatment under a nitrogen atmosphere. 10 parts of 4-(methylthio)benzaldehyde represented by following formula (30) was dripped at this solution, and it heated at 80 degreeC, and started reaction. After stirring for 30 minutes, the reaction liquid was cooled to 3° C. and the precipitated crystals were collected by suction filtration. The recovered crystals were purified by recrystallization using a large amount of ethanol to obtain 7.6 parts of an intermediate compound represented by the following formula (31).

[0211]

[0212] (step 2) synthesis of the intermediate compound represented by formula (32)

[0213] In a flask equipped with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com