Single-stator three-degree-of-freedom spherical ultrasonic motor and its excitation method

A technology of ultrasonic motor and degree of freedom, which is applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., and can solve the problems of complex overall structure, poor dynamic performance, and bulky volume , to achieve the effect of high energy density, no electromagnetic interference, and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

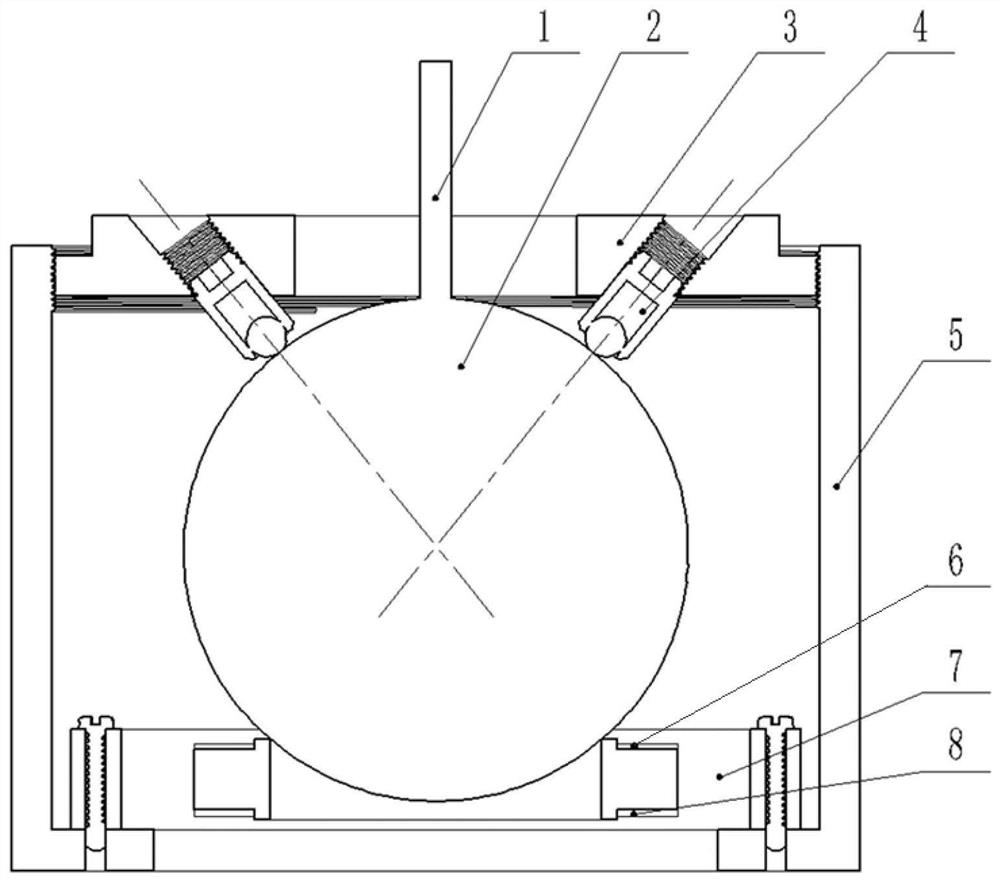

[0042] Below in conjunction with accompanying drawing, the technical scheme of the present invention is described in further detail:

[0043] The present invention may be embodied in many different forms and should not be considered limited to the embodiments described herein. Rather, these embodiments are provided so that this disclosure will be thorough and complete, and will fully convey the scope of the invention to those skilled in the art. In the drawings, components are exaggerated for clarity.

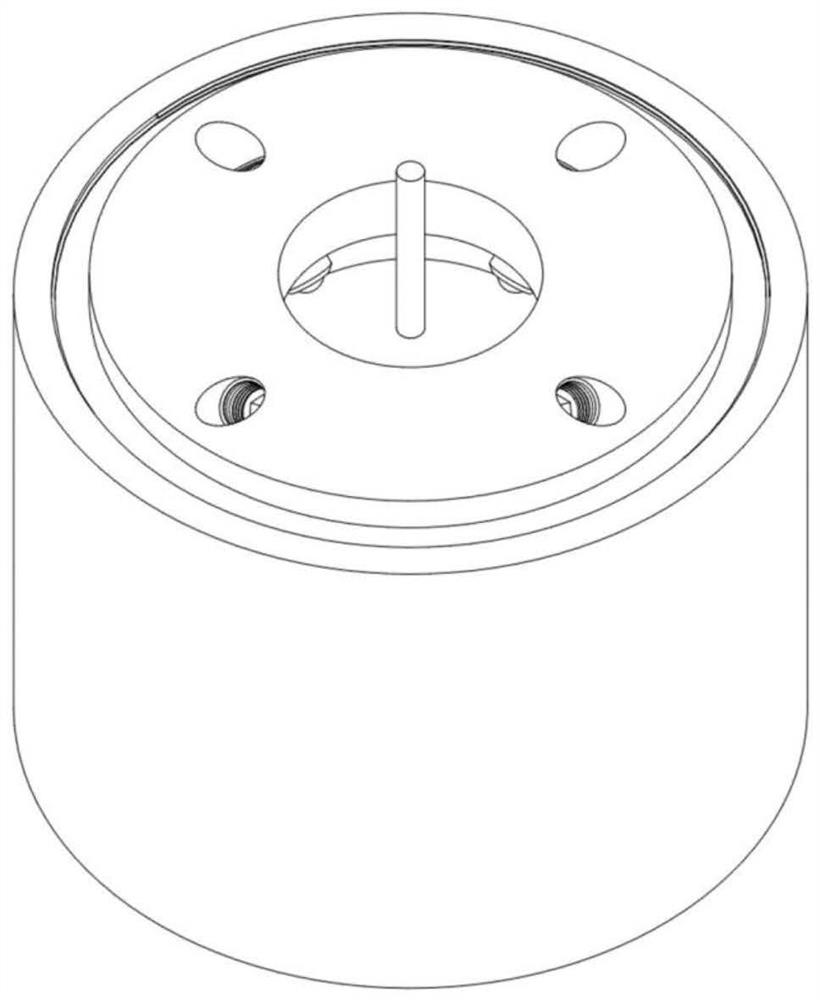

[0044] like figure 1 , figure 2 As shown, the present invention discloses a single-stator three-degree-of-freedom spherical ultrasonic motor, which includes a casing, an end cover, N ball-head plungers, a rotor, an output shaft, a stator and a piezoelectric drive module, where N is greater than or equal to 3 Natural number.

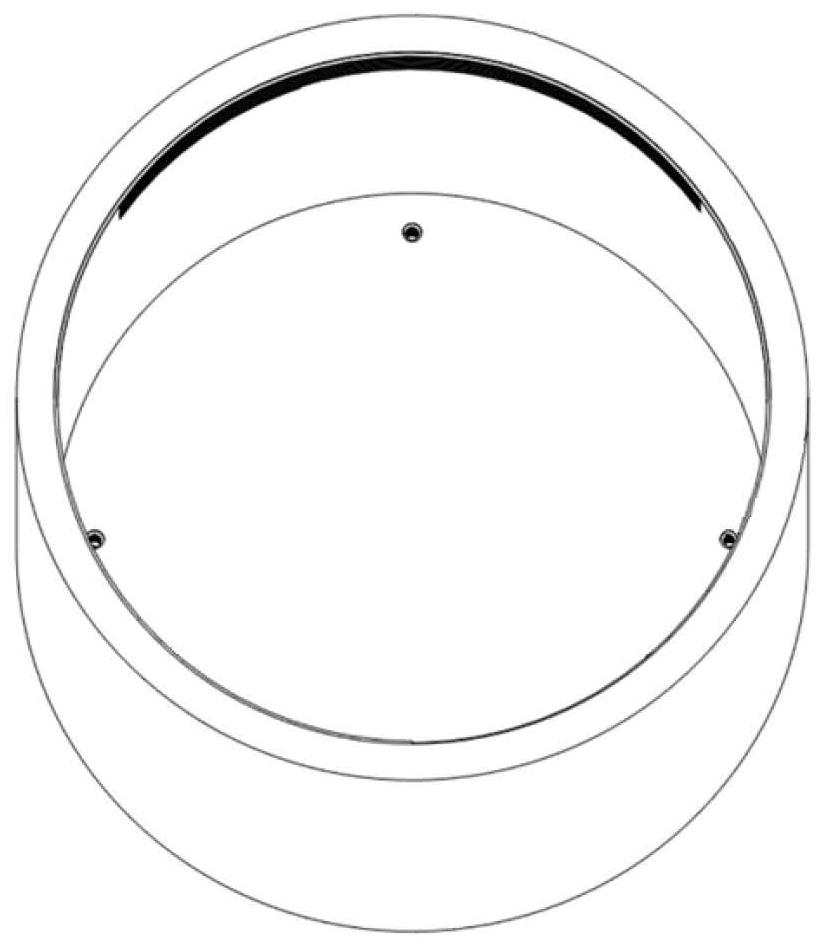

[0045] like image 3 As shown, the casing is a hollow cylinder with an open upper end, and the inner wall of the upper end of the side wall is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com