Predictive maintenance model and maintenance method for wave-activated generator

A generator, predictive technology, used in forecasting, electrical digital data processing, CAD numerical modeling, etc., can solve problems such as loss, and achieve the effect of overcoming strong subjectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] Embodiment 1 provides a wave generator predictive maintenance model, including:

[0089] Z c =w * x c ;

[0090] Among them, Z c for the current data as x c at w * The value obtained after vector axis projection;

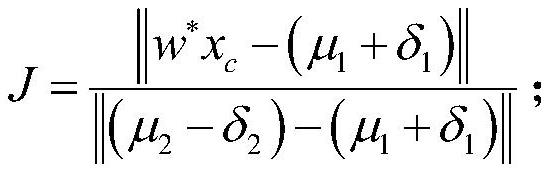

[0091] Then the current health degree J of wave generator operation is:

[0092] When Z c ≤μ 1 +δ 1 When , the health degree J of wave generator operation is 0;

[0093] When Z c ≥ μ 2 -δ 2 , the health degree J of the wave generator is 1;

[0094] when μ 1 +δ 1 ≤Z c ≤μ 2 -δ 2 When , the health degree J of wave generator operation is:

[0095]

[0096] w * is the best transformation vector; μ 1 works fine for class data in w * Mean value of the data obtained after vector axis projection; μ 2 For the data of the failure category in w * The mean value of the data obtained after vector axis projection; δ 1 works fine for class data in w * The standard deviation of the data obtained after vector axis projection; δ 2 For the data of ...

Embodiment 2

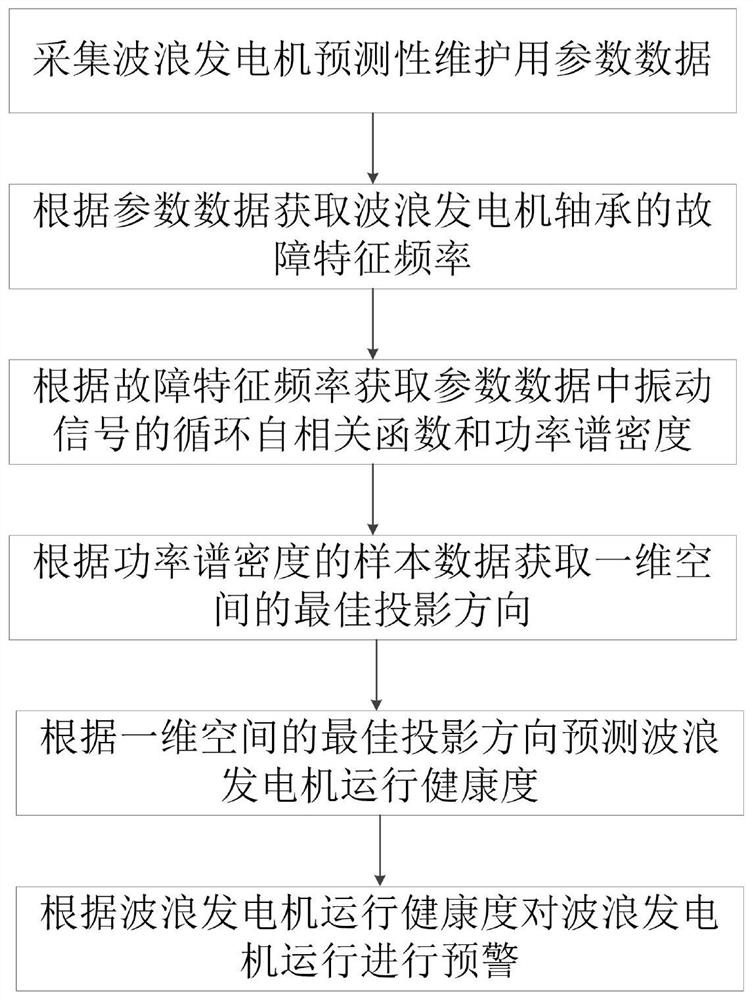

[0099] figure 1 It is a flow chart of the wave generator predictive maintenance method involved in the present invention.

[0100] like figure 1 As shown, on the basis of embodiment 1, this embodiment 2 provides a method for predictive maintenance of wave generators, including: collecting parameter data for predictive maintenance of wave generators; acquiring fault characteristics of wave generator bearings according to parameter data Frequency; obtain the circular autocorrelation function and power spectral density of the vibration signal in the parameter data according to the fault characteristic frequency; obtain the best projection direction of one-dimensional space according to the sample data of power spectral density; predict the wave according to the best projection direction of one-dimensional space Generator operation health; and early warning of wave generator operation based on wave generator operation health, which realizes prediction and early warning of wave ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com