High-voltage interlocking detection circuit and fault detection method

A high-voltage interlock circuit and high-voltage interlock technology, applied in continuity testing, electrical connection testing, etc., can solve problems such as low detection efficiency, inability to accurately locate fault locations, and waste of manpower and material resources, so as to avoid sick work and improve The effect of troubleshooting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below with reference to the accompanying drawings.

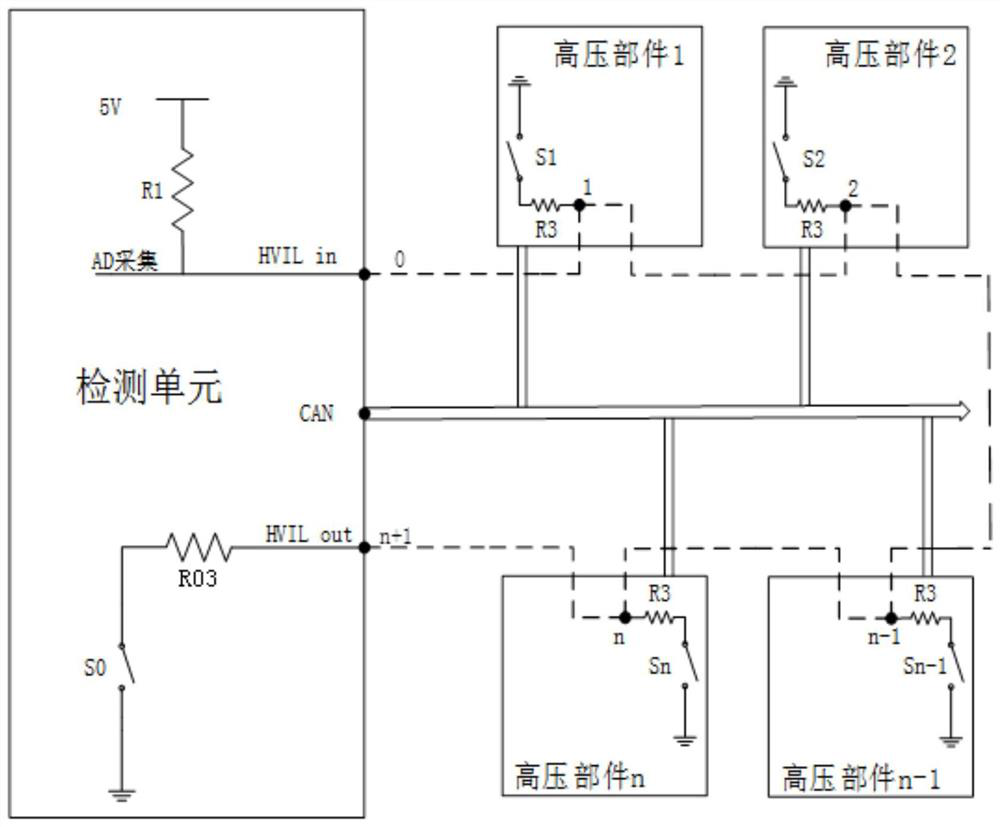

[0044] The high-voltage system circuit includes a CAN communication circuit and N detection switch circuits.

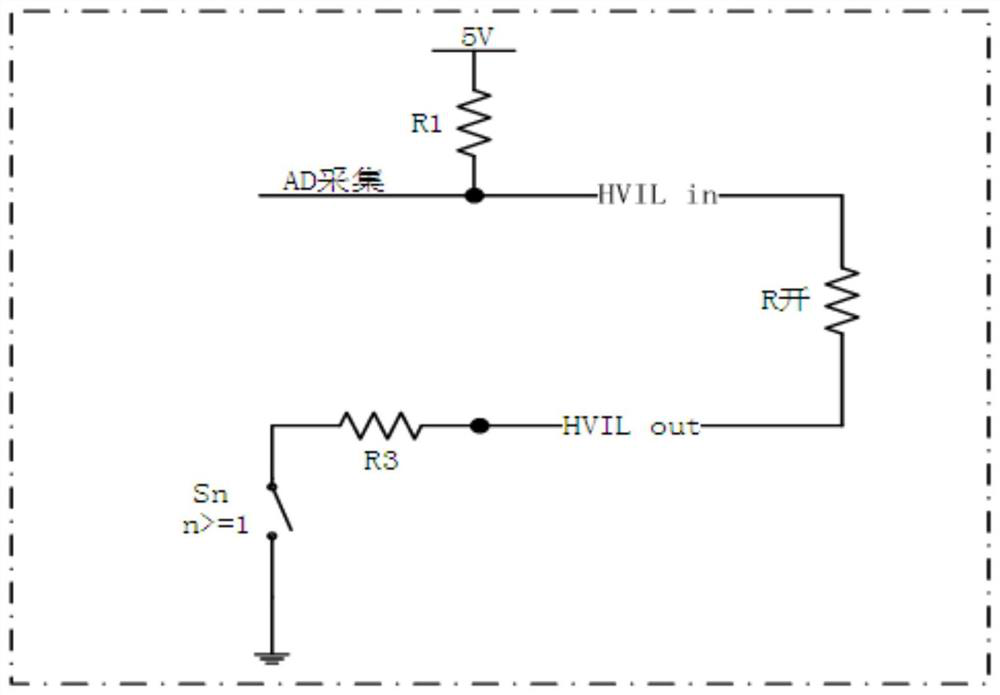

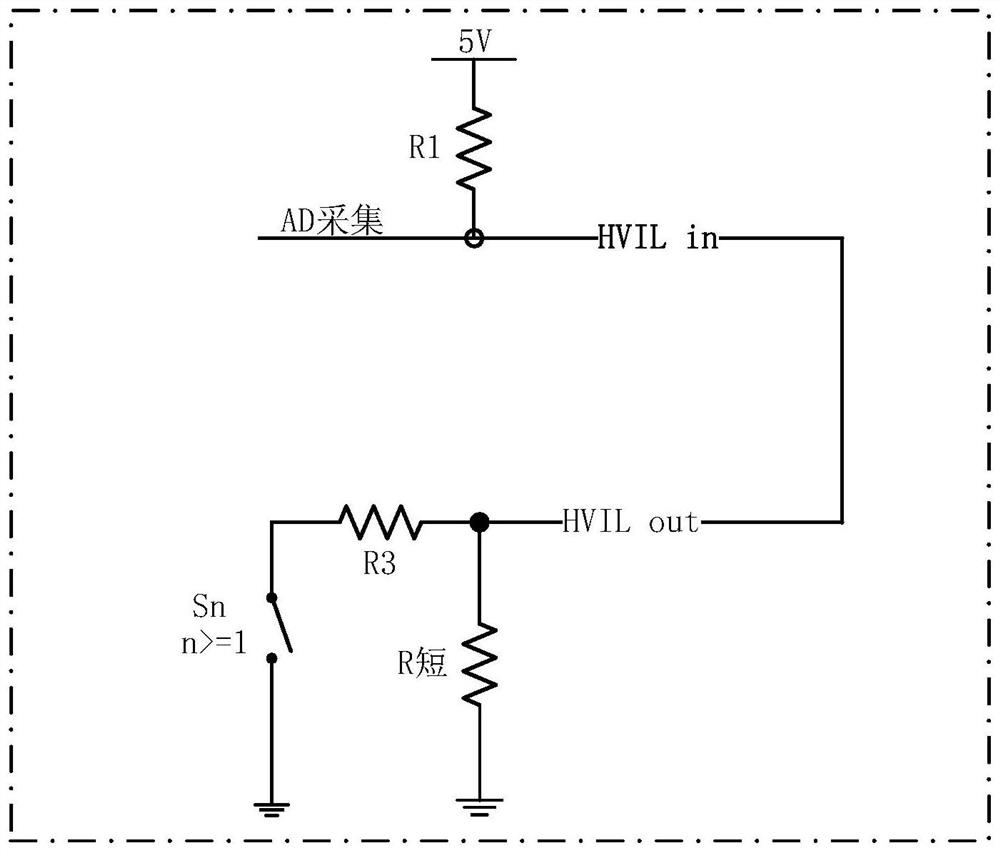

[0045] The detection switch circuit includes a voltage dividing resistor R3 and a controllable switch; the lower end of the voltage dividing resistor R3 is used in series with a high-voltage component, and then connected in series with the upper end of the controllable switch, and the lower end of the controllable switch is grounded; the voltage dividing resistors of N detection switch circuits The upper ends of R3 are electrically connected to each other; the N detection switch circuits include a first detection switch circuit 1, a second detection switch circuit 2, a third detection switch circuit 3, up to the Nth detection switch circuit n; the first detection switch circuit 1 includes The piezoresistor R3 and the first controllable switch S1, the second de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com