Barrel shear tester for soil-rock contact surface mechanics combined with 3D printing technology

A 3D printing and shearing test technology, applied in the direction of applying stable shear force to test the strength of materials, scientific instruments, instruments, etc., can solve the problems of reduced shear area and difficulty in obtaining residual strength, etc., to ensure shear Area, the effect of avoiding size effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

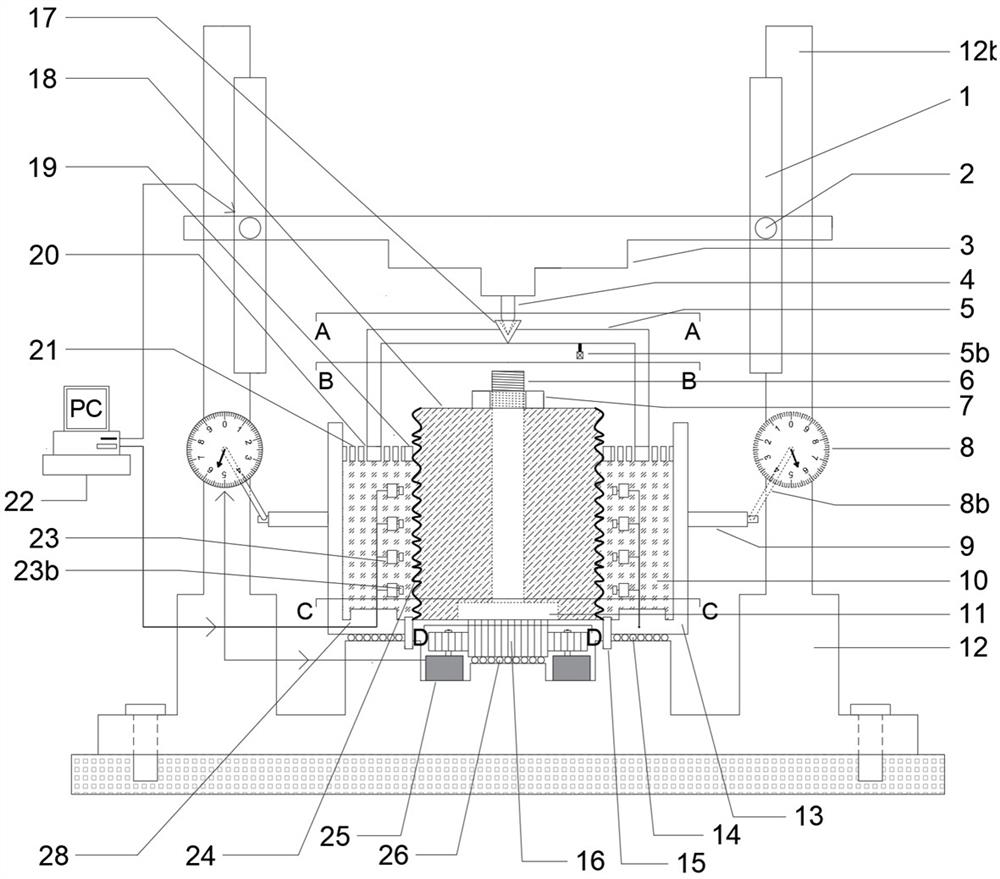

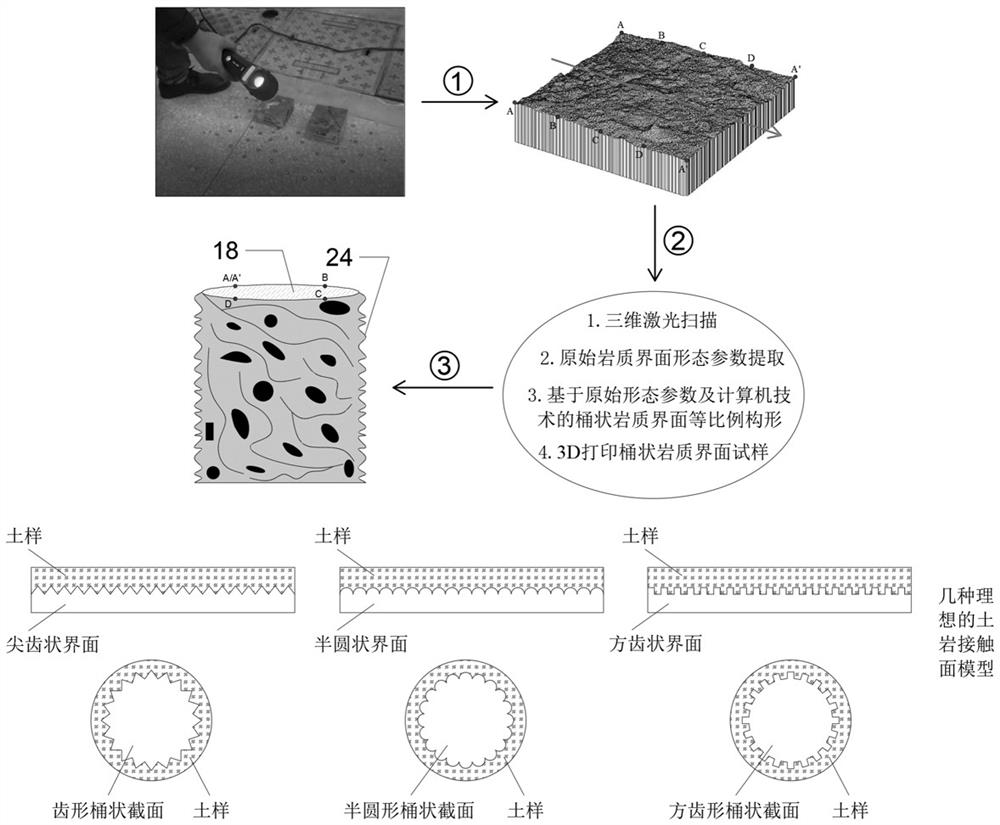

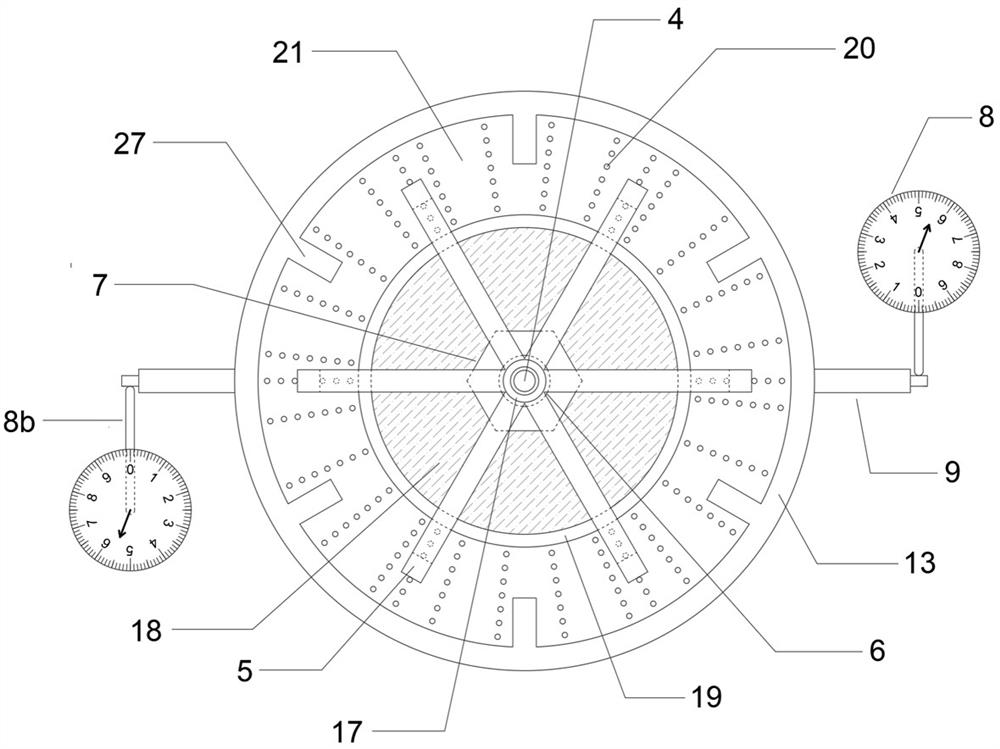

[0042]This embodiment is a soil-rock contact surface mechanics barrel shear tester combined with 3D printing technology, which mainly includes a frame, a rock sample fixing mechanism, a shear box 13, an axial compression mechanism, a rotary drive mechanism, and a shear monitoring mechanism. Mechanism and computer 22 for performing shear mechanics testing using barrel rock sample 18 and annular soil sample 10 formed around barrel rock sample 18 and in contact with the outer interface of barrel rock sample 18, wherein barrel rock sample 18 The outer rock interface 24 is formed by coordinate transformation and isometric configuration of the point cloud data obtained by 3D laser scanning of the natural rock interface, and then combined with 3D printing technology, the barrel-shaped rock sample 18 and its outer rock interface 24 are integrated. and print.

[0043] In this example, the rock sample fixing mechanism has a bolt 6, a strip gusset 11 and a nut 7, wherein the bolt 6 penet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com