Gear convenient to lubricate

A technology of gears and gear teeth, which is applied in the field of gears that are easy to lubricate, can solve problems such as inability to lubricate gears, poor smooth performance, and low use strength, and achieve the effects of simple structure, uniform lubrication, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

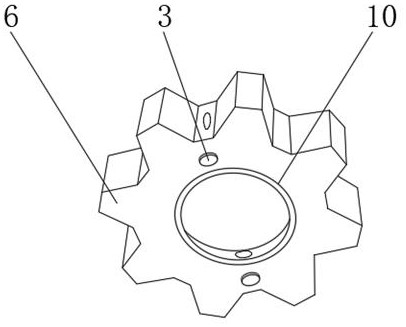

[0029] Such as Figure 1-4 As shown, a gear that is convenient for lubrication includes a rotating gear 1, a driving gear 6 and a gear body 9, a rotating shaft 8 is arranged between the driving gear 6 and the gear body 9, and a lubricating oil adding pipeline mechanism is positioned on the inner wall of the driving gear 6 3. The outer side of the driving gear 6 is fixedly connected with the No. 2 gear tooth 5, the inner wall of the rotating gear 1 is provided with a gear wall 2, the outer side of the rotating gear 1 is fixedly connected with the No. 1 gear tooth 4, and the outer surface of the rotating gear 1 is fixedly connected with an anti-corrosion The derusting strengthening mechanism 7, a bearing 10 is arranged between the drive gear 6 and the rotating shaft 8;

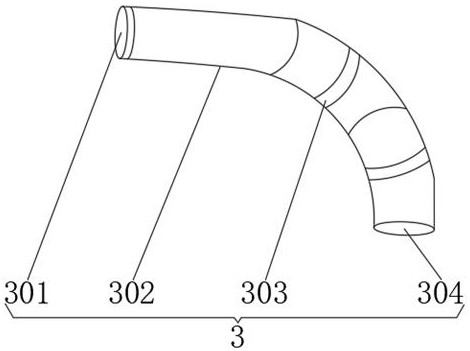

[0030] The lubricating oil adding pipeline mechanism 3 includes a sliding cover 301, a pipeline 302, a retaining member 303, an oil outlet 304, a sealing ring 305, and a drip irrigation port 306. The sliding cov...

Embodiment 2

[0034] Such as Figure 1-4 As shown, a gear that is convenient for lubrication includes a rotating gear 1, a driving gear 6 and a gear body 9, a rotating shaft 8 is arranged between the driving gear 6 and the gear body 9, and a lubricating oil adding pipeline mechanism is positioned on the inner wall of the driving gear 6 3. The outer side of the driving gear 6 is fixedly connected with the No. 2 gear tooth 5, the inner wall of the rotating gear 1 is provided with a gear wall 2, the outer side of the rotating gear 1 is fixedly connected with the No. 1 gear tooth 4, and the outer surface of the rotating gear 1 is fixedly connected with an anti-corrosion The derusting strengthening mechanism 7, a bearing 10 is arranged between the drive gear 6 and the rotating shaft 8;

[0035] The anti-corrosion and rust-removing strengthening mechanism 7 comprises an anti-corrosion layer 701, a rust-removing layer 702, a reinforcement layer 703, a wear-resistant layer 704, and a connecting lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com