High goods shelf goods taking device for logistics

A shelf and logistics technology, applied in the field of high-shelf pick-up devices for logistics, can solve problems such as cumbersome operation, inability to pick up goods, and limited volume of goods taken

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS As will be further detailed in connection with the accompanying drawings, the technical solution of the present invention is more readily understood and grasped.

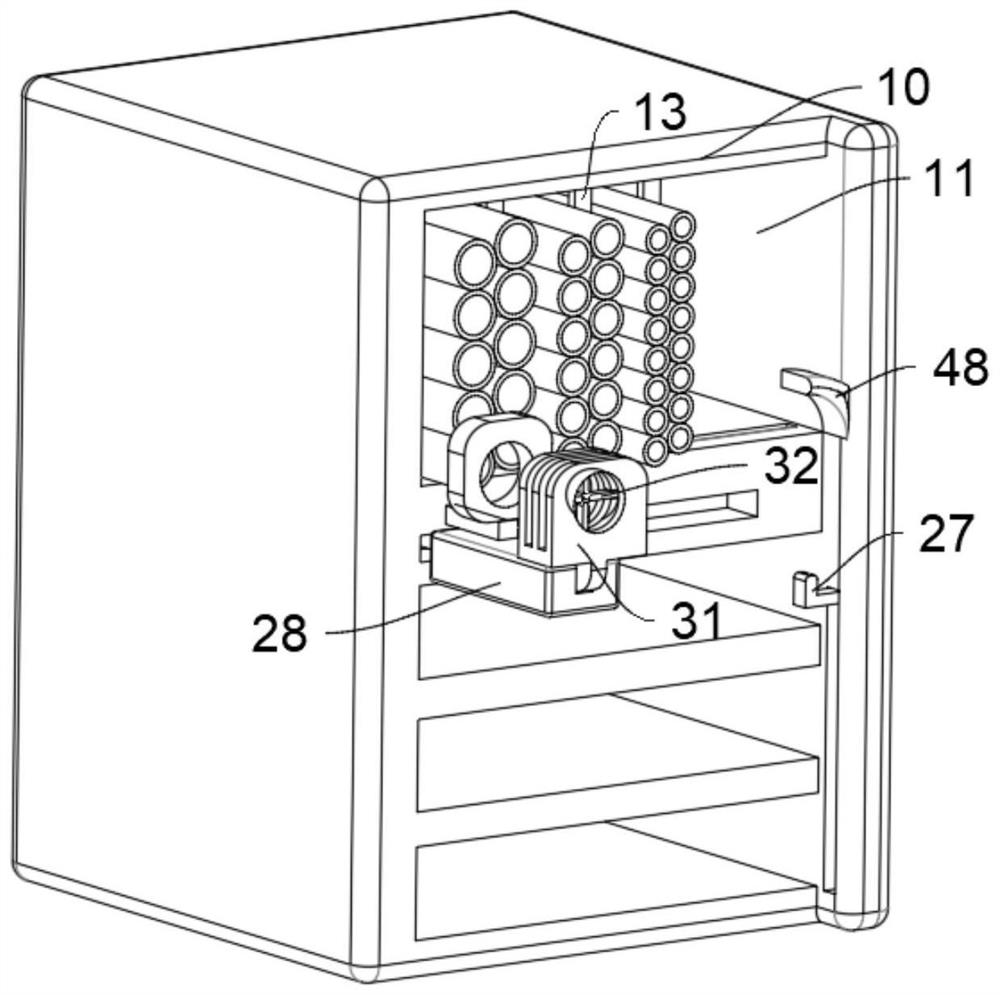

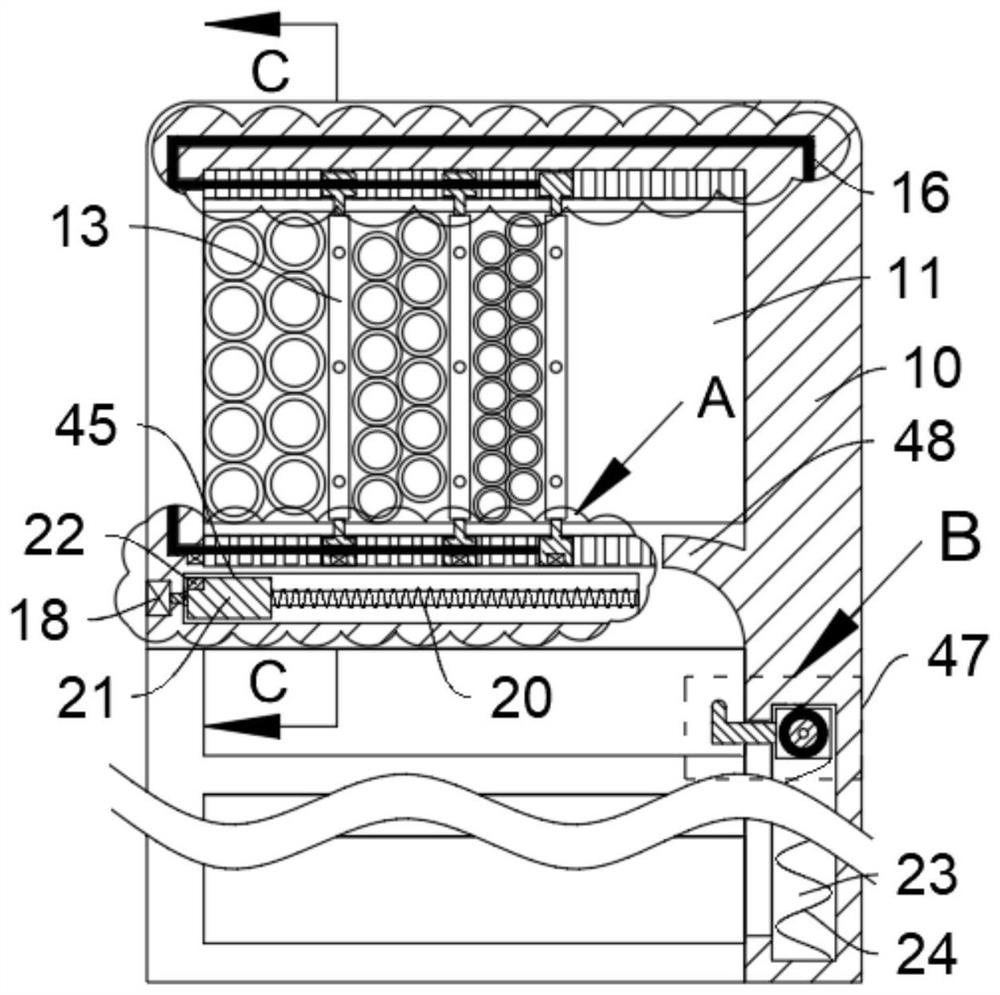

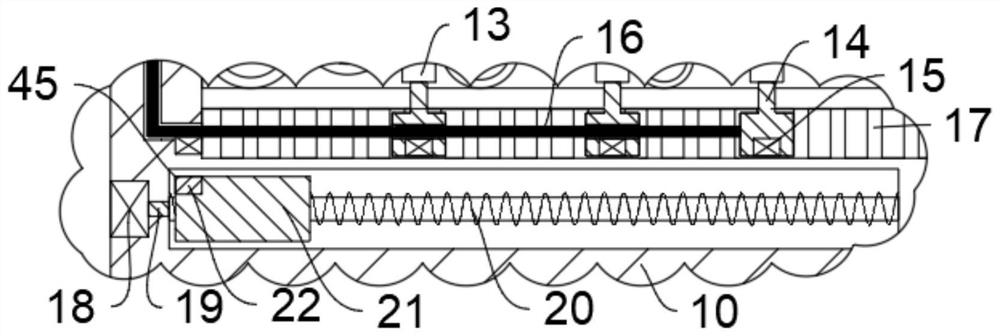

[0032] Refer figure 2 , image 3 and Figure 5 As shown, this embodiment provides a high shelf pick-up device for a logistics, which can be taken off for the designated pipe, and the remaining pipes can be organized.

[0033] Including shelf 10, at least one warehouse 11 is provided inside the shelf 10, wherein the shelf 10 is provided with a pipe 46 and a finishing mechanism 47 for taking a tube; a pipeline 47 is placed inside the tube 11; The tank 11 is slidable with a push plate 13, the push plate 13 for consolidating the pipe; the finishing mechanism 47 includes a constant mechanism and a drawn cord 16, the constant mechanism and the shelf 10 Vertically, the constant force mechanism is connected to the push plate 13 by the pull tope 16, which is removed from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com