Paste spraying equipment capable of continuously spraying

A spraying equipment and pulping technology, applied in auxiliary molding equipment, clay preparation device, control device, etc., can solve the problems of continuous spraying, uncontrollable water-cement ratio, etc., and achieve the effect of accurate control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

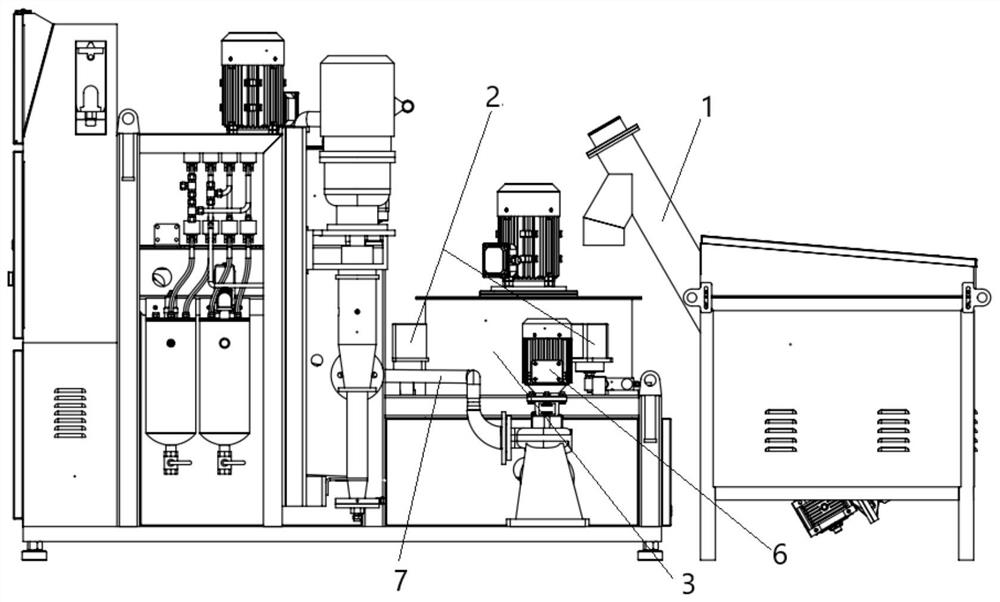

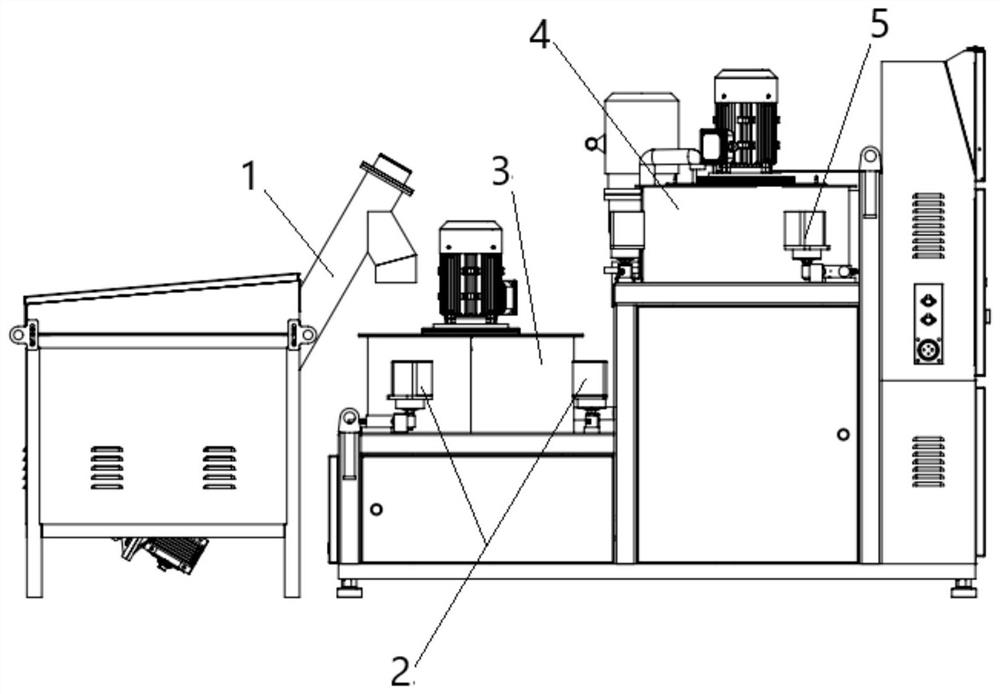

[0019] Below, the present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

[0020] A slurry spraying equipment for continuous spraying, including a feeding structure, a pulping structure and a spraying structure, and a host computer; the pulping structure includes a pulping barrel and a slurry storage barrel, and the bottom of the pulping barrel There is a pouring pump 6, the inlet end of the pouring pump is connected to the pulping barrel, and the outlet end of the pouring pump is connected to the top of the stocking barrel through a pipeline 7; the bottom of the stocking barrel and the bottom of the stocking barrel Both are equipped with weighing sensors; both the pulping barrel and the pulp storage barrel are equipped with stirring blades, and the stirring blades of the two are respectively driven by a pulping motor and a pulp storage motor;

[0021] The feeding structure includes a water feeding structure and a ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com