Automatic root removing equipment for hydroponic vegetables

A technology for hydroponic vegetables and root equipment, applied in application, food processing, metal processing, etc., can solve the problems of complex operation and high labor cost, and achieve the effect of improving operation speed, reducing labor cost, and facilitating collection and processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

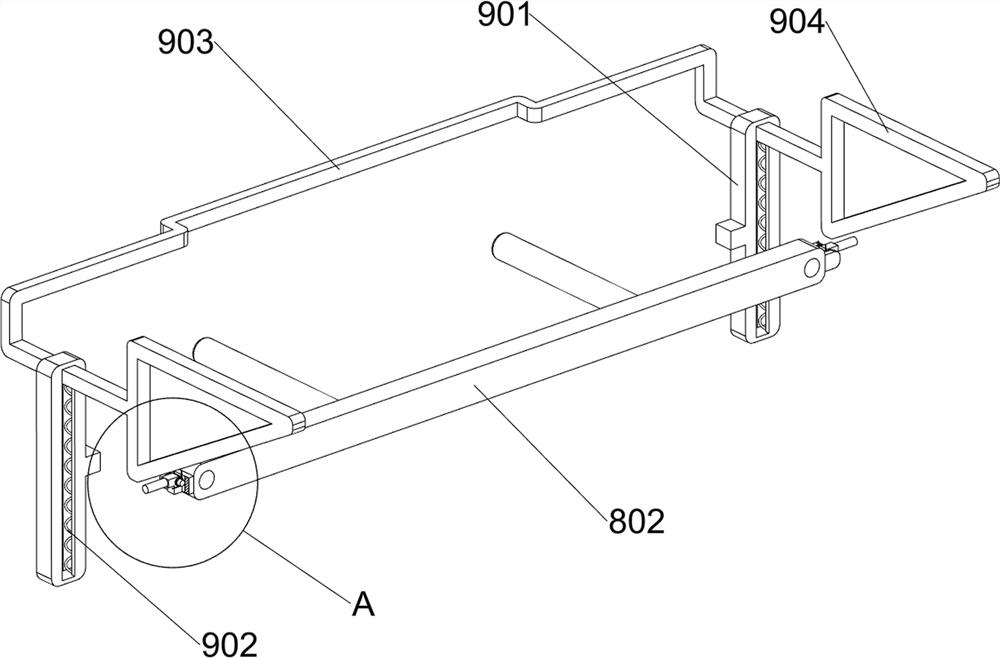

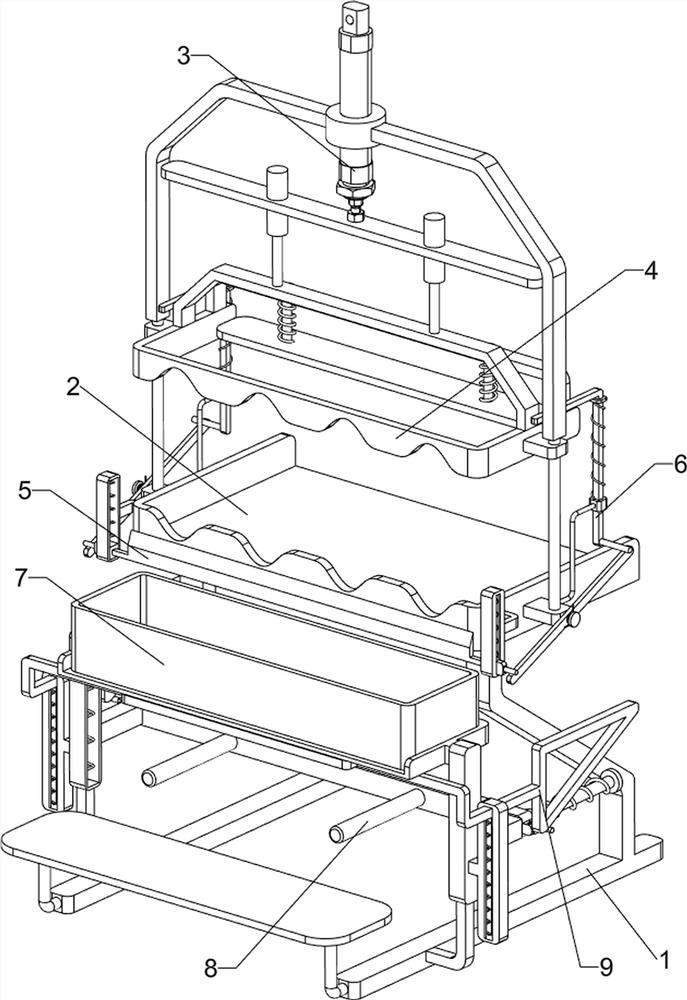

[0071] A kind of automatic derooting equipment for hydroponic vegetables, such as figure 1 and figure 2 As shown, it includes a first support frame 1, a placement plate 2, a pressing assembly 3, a clamping assembly 4 and a cutting assembly 5, and a placement plate 2 is connected between the upper sides of the first support frame 1 on the left and right sides, and the placement plate 2 A pressing assembly 3 is connected to the upper side, a clamping assembly 4 is connected to the lower side of the pressing assembly 3, and a cutting assembly 5 is connected to the left and right sides of the placing plate 2 .

[0072]When the device needs to be used, the user can place the vegetables on the placement plate 2, activate the pressing assembly 3, and the telescopic rod of the pressing assembly 3 is extended, so that the pressing assembly 3 moves downward, and the pressing assembly 3 moves downward. The movement drives the clamping assembly 4 to slide downward, and when the clamping...

Embodiment 2

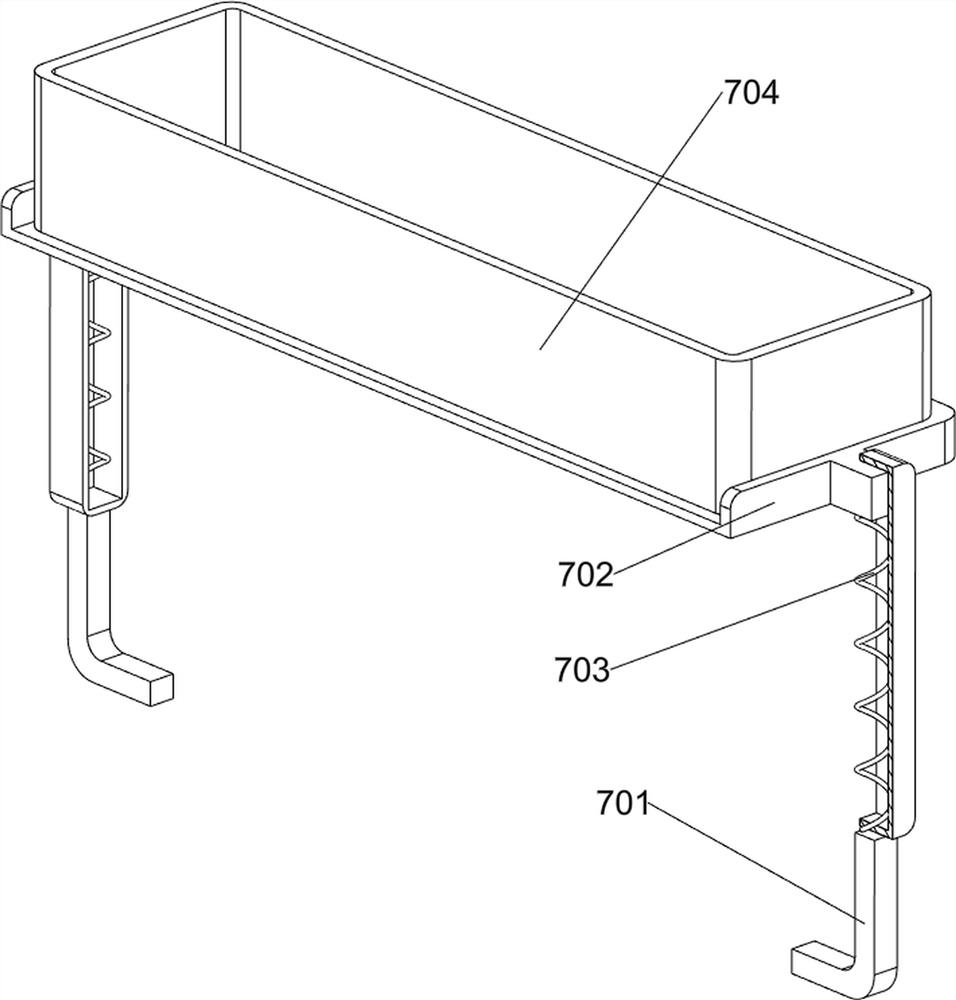

[0074] On the basis of Example 1, such as image 3 As shown, the pressing assembly 3 includes a second support frame 301, a cylinder 302, a first connecting rod 303, a first pressing rod 304 and a first spring 305, and the upper side of the placement plate 2 is connected with the second support frame 301, the second The inner side of the support frame 301 is connected with a cylinder 302, the end of the telescopic rod of the cylinder 302 is connected with a first connecting rod 303, and the first connecting rod 303 is slidably connected with a first pressure rod 304, and the upper side of the first pressure rod 304 is connected with the first First springs 305 are symmetrically connected between the top walls of the rods 303 .

[0075] When the device needs to be used, the user can place the vegetables on the placement plate 2, start the cylinder 302, the stretch rod of the cylinder 302 drives the first connecting rod 303 to move downward, and the downward movement of the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com