Refrigerant recovery machine intelligent control recovery method

A technology of intelligent control and refrigerant recovery, applied in the direction of refrigerators, refrigerants, refrigeration components, etc., can solve the problems of easily damaged recovery machines, safety accidents, and large impacts, so as to achieve low human impact, high recovery efficiency, and improved use. safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

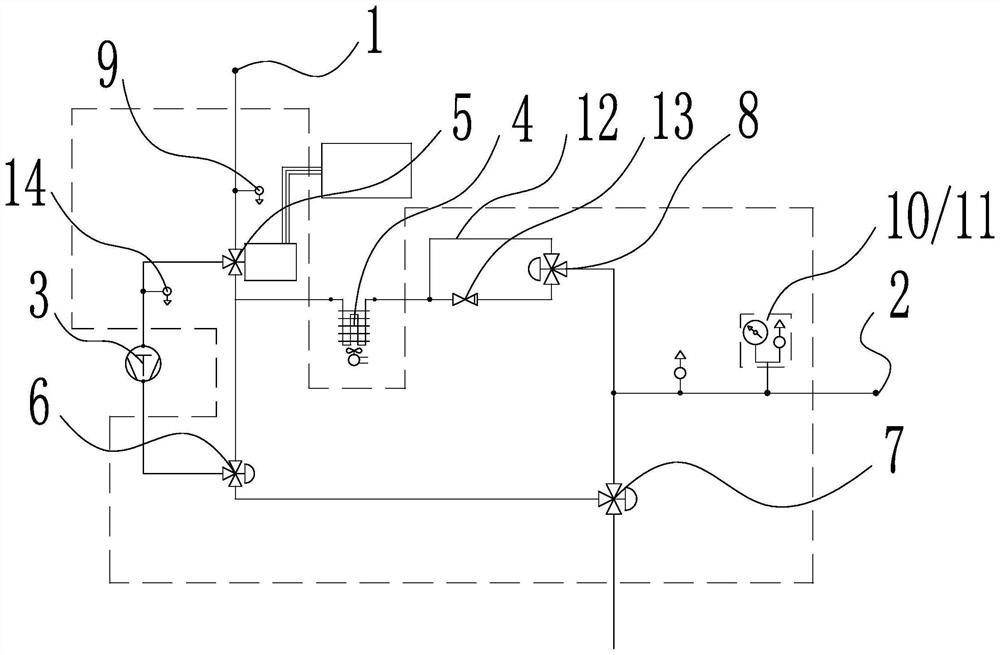

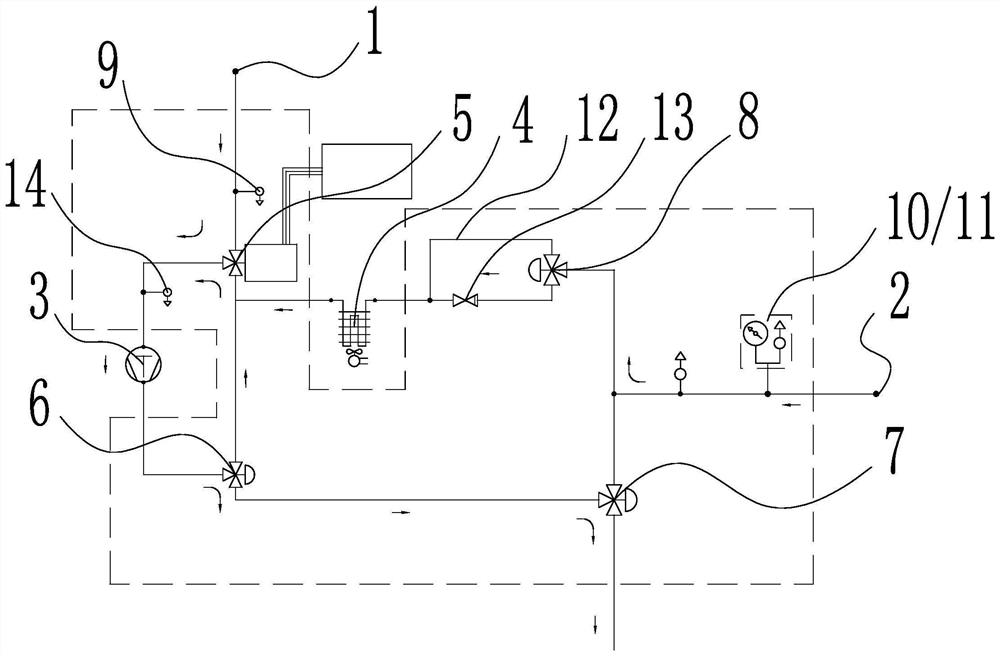

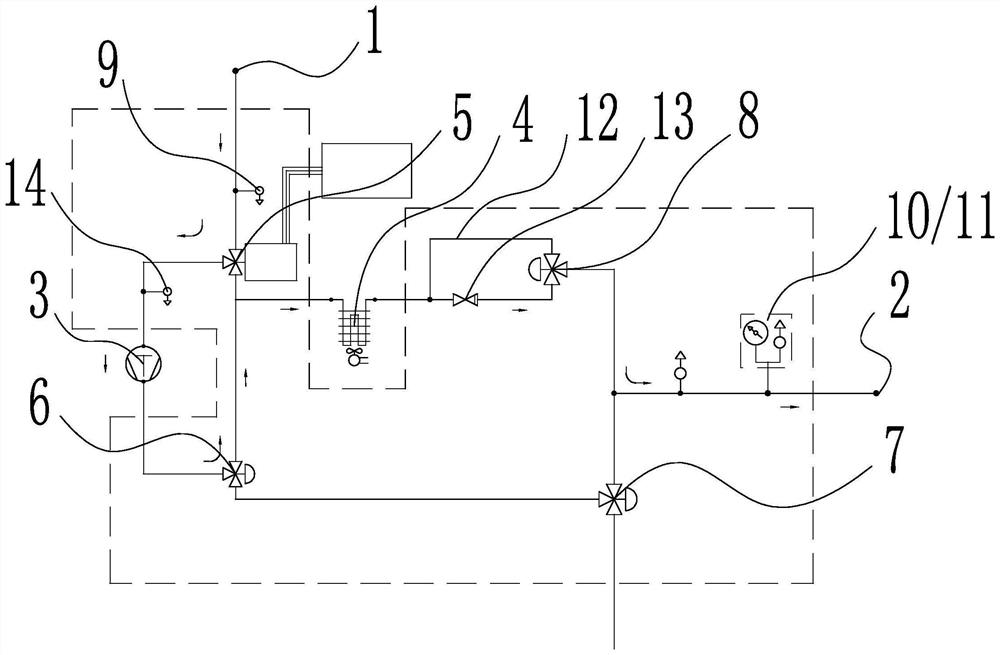

[0038] like figure 1 As shown, the intelligent control pipeline structure of a refrigerant recovery machine of the present invention includes a compressor 3 and a condenser 4 connected in parallel between the air inlet 1 and the air outlet 2, and the compressor 3 and the condenser 4 pass through the main valve. 5 is connected to the intake port 1, the compressor 3 is connected to the exhaust port 2 through the first synchronization valve 6 and the air release valve 7 in turn, the condenser 4 is connected to the exhaust port 2 through the third synchronization valve 8, and the main The valve 5 is connected to the first synchronizing valve 6 through the intermediate pipeline, wherein the main valve 5, the first synchronizing valve 6, the third synchronizing valve 8 and the air bleed valve 7 are all three-way valves. A low pressure sensor 9 is installed on the corresponding pipeline between the valves 5, a high pressure sensor 10 and a high pressure switch 11 are installed on the...

Embodiment 2

[0057] like figure 1 As shown, the intelligent control pipeline structure of a refrigerant recovery machine of the present invention includes a compressor 3 and a condenser 4 connected in parallel between the air inlet 1 and the air outlet 2, and the compressor 3 and the condenser 4 pass through the main valve. 5 is connected to the intake port 1, the compressor 3 is connected to the exhaust port 2 through the first synchronization valve 6 and the air release valve 7 in turn, the condenser 4 is connected to the exhaust port 2 through the third synchronization valve 8, and the main The valve 5 is connected to the first synchronizing valve 6 through the intermediate pipeline, wherein the main valve 5, the first synchronizing valve 6, the third synchronizing valve 8 and the air bleed valve 7 are all three-way valves. A low pressure sensor 9 is installed on the corresponding pipeline between the valves 5, a high pressure sensor 10 and a high pressure switch 11 are installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com