Safety protection device for mine and using method

A safety protection device and mine technology, applied in safety devices, components of pumping devices for elastic fluids, dust prevention, etc., can solve problems such as increased maintenance costs, increased labor workload of staff, and coal silicosis in miners , to achieve the effects of reducing production costs and later maintenance costs, improving economic practicability, and improving air quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

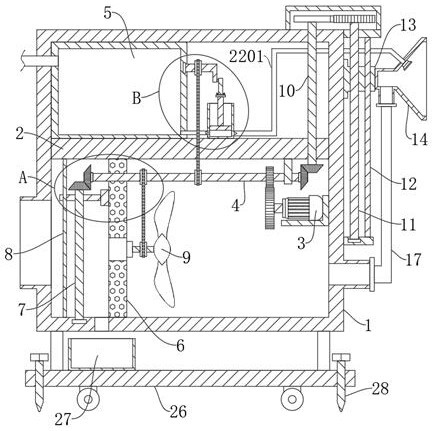

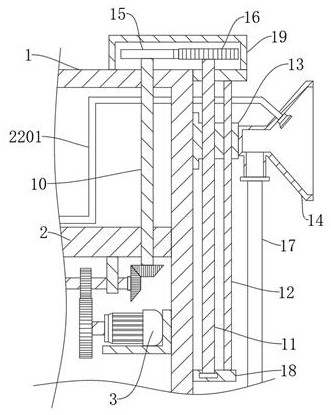

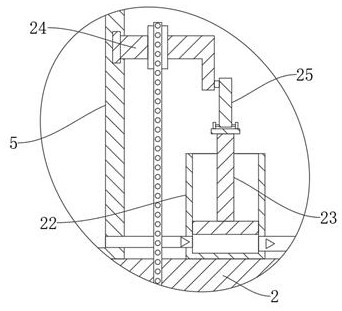

[0033] refer to Figure 1-5, a safety protection device for mines, including a box body 1, also includes: a fixed plate 2, fixedly connected in the box body 1; a transmission assembly, connected to the fixed plate 2; a motor 3, fixedly connected in the box body 1 , used to drive the transmission assembly to rotate; the filter plate 6 is fixedly connected to the side of the box body 1 near the air inlet; the impeller 9 is rotatably connected to the filter plate 6 and connected to the transmission assembly; the dust removal mechanism is connected to the transmission assembly, Used to remove dust on the filter plate 6; the air outlet cover 14 is connected to the air outlet of the box body 1 through the air pipe 17; the lifting mechanism is connected to the transmission assembly and is used to drive the air outlet cover 14 to move; the water tank 5 is fixedly connected to the On the fixed plate 2; the water spray mechanism is connected with the transmission assembly, and is used t...

Embodiment 2

[0036] refer to Figure 1-5 , a safety protection device for mines, which is basically the same as Embodiment 1, furthermore: the transmission assembly includes a first transmission shaft 4, a second transmission shaft 10, the output end of the motor 3 is fixedly connected with a first gear, the second A transmission shaft 4 is fixedly connected with a second gear meshed with the first gear, a fixed block is fixedly connected with the fixed plate 2, the first transmission shaft 4 is connected to the fixed block in rotation, and the first transmission shaft 4 is far away from the motor 3 One end runs through the filter plate 6 and is connected to the power input end of the dust removal mechanism. The second transmission shaft 10 is connected to the side of the box body 1 close to the motor 3. The end of the first transmission shaft 4 close to the motor 3 is fixedly connected with a first Bevel gear, the second transmission shaft 10 is fixedly connected with the second bevel gea...

Embodiment 3

[0038] refer to figure 1 and Figure 4 , a safety protection device for mines, which is basically the same as that of Embodiment 1, furthermore: the dust removal mechanism includes a first reciprocating screw rod 7, a moving rod 20, and a scraper 21, and the first reciprocating screw rod 7 is rotatably connected to the box One end of the body 1 near the air inlet, the moving rod 20 is rotatably connected with the first reciprocating screw rod 7 through threads, the scraper 21 is slidably connected to the filter plate 6, and is fixedly connected with the moving rod 20, and the first transmission shaft 4 is close to the first One end of the reciprocating screw mandrel 7 is fixedly connected with the third bevel gear, and the first reciprocating screw mandrel 7 is fixedly connected with the fourth bevel gear meshed with the third bevel gear. When the first transmission shaft 4 rotates, the third bevel gear can be driven. The bevel gear rotates, the third bevel gear drives the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com