Flood drainage method for construction period and operation period of channel type waste slag field

A technology for waste slag yard and operation period, which is applied in the field of flood discharge during the construction period of channel-type waste slag yard and during operation period, can solve the problem that the design elevation of the slag yard does not match the actual slag heap elevation, the construction of the flood discharge channel is difficult, and the two sides Steep mountain terrain and other problems, to achieve the effect of reducing soil erosion, low cost, and reducing disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

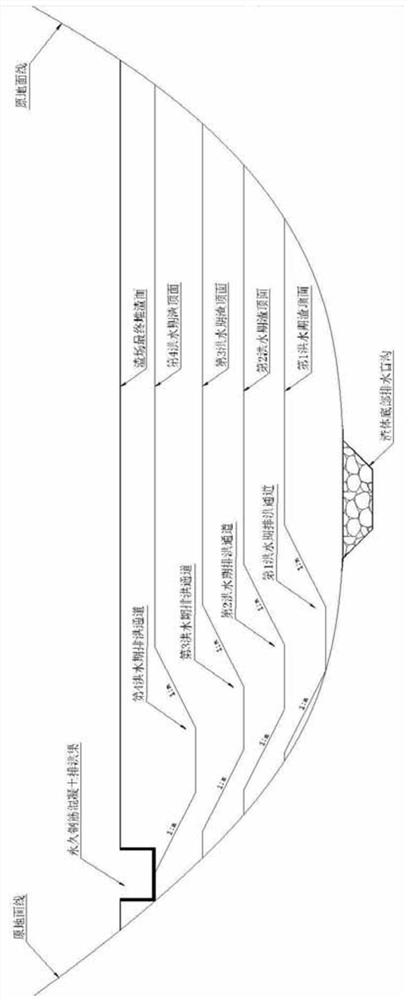

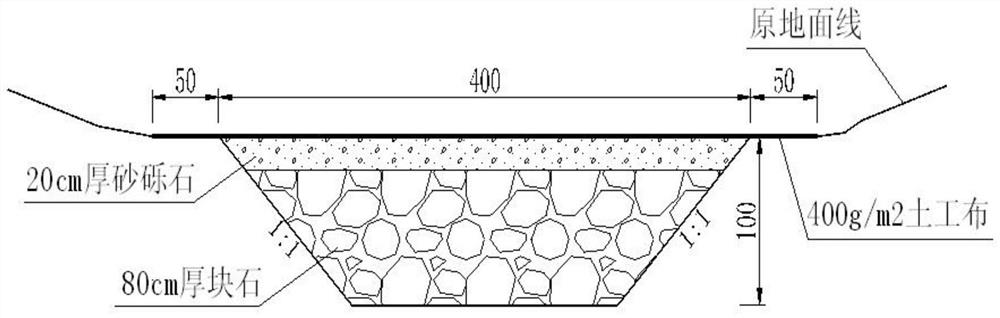

[0063] (1) Drainage blind ditch at the bottom of the slag body

[0064] Before slag stacking, a drainage blind ditch is arranged at the bottom of the slag body. The blind ditch is arranged along the lowest part of the original ditch ground. Considering the convenience of construction, the blind ditch has a trapezoidal cross-section and is filled with block stones and gravels. The bottom width is 2.0m and the slope ratio is 1:1. , 1.0m high, 0.8m block stone + 0.2m gravel, 400g / m wrapped at the top of the blind ditch 2 Non-woven fabric to prevent the blind ditch from being blocked by fine earth and rocks;

[0065](2) Temporary flood discharge channels

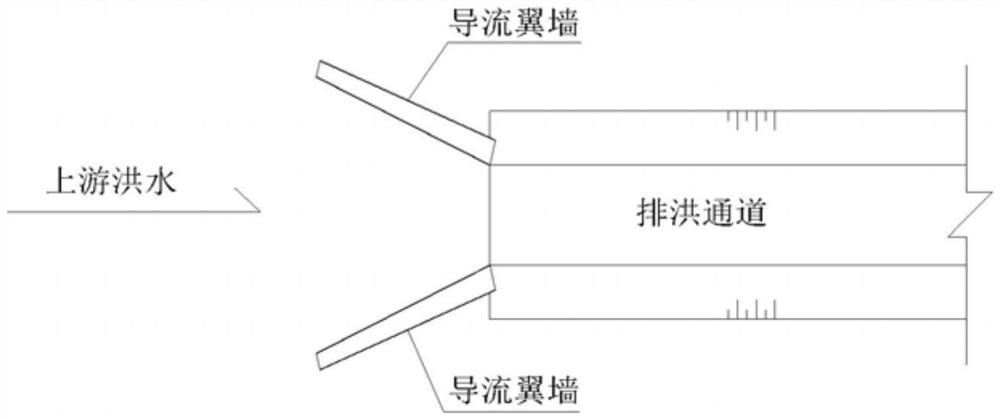

[0066] (1) Layout of temporary flood discharge channels

[0067] During the period of slag stacking in the slag yard, reserve a flood discharge channel for the first flood period on the slag surface near the hillside on the side of the slag yard, and use 400-700g / m 2 The PVC waterproof coated canvas is used for lining, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com