Preparation method of anti-bioadhesion super-hydrophobic suspension

A suspension and super-hydrophobic technology, which is applied to biocide-containing paints, anti-fouling/underwater coatings, coatings, etc., can solve the problems of unfavorable super-hydrophobic surface preparation and application, expensive equipment, complicated methods and processes, etc., to achieve Facilitate large-scale preparation and application, reduce adhesion, and simple process equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

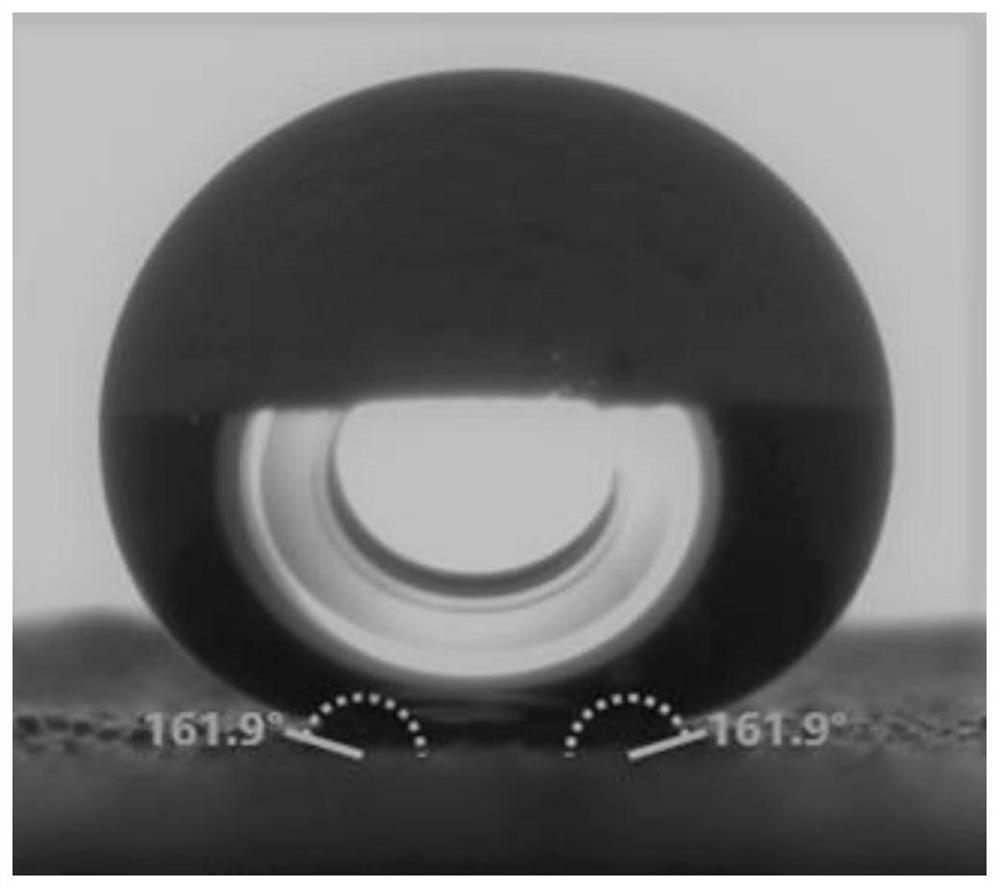

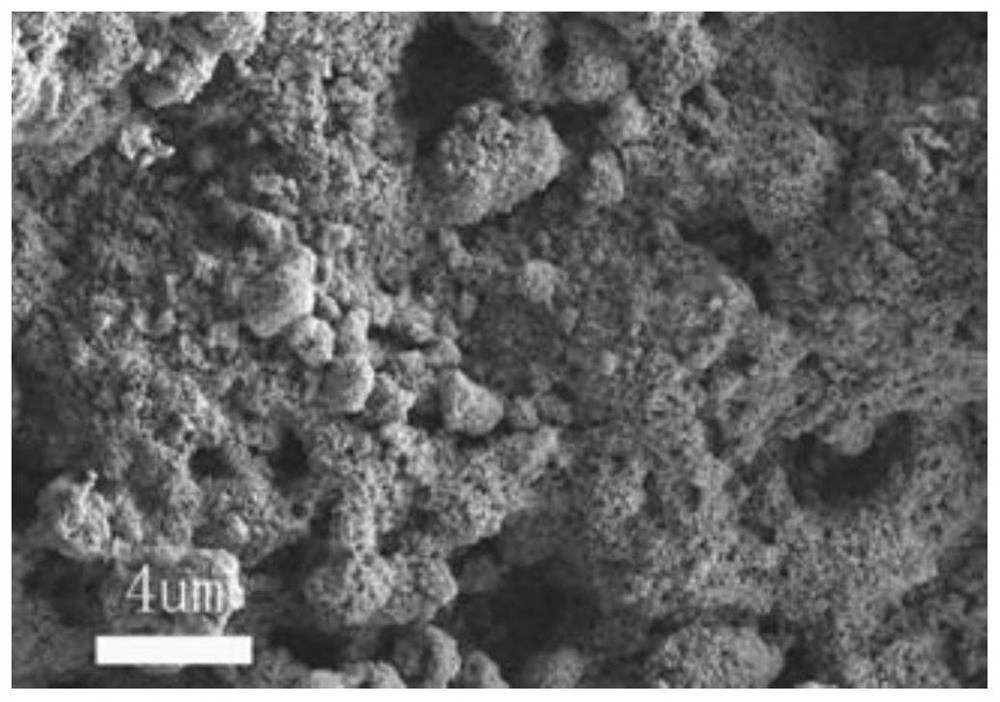

Embodiment 1

[0035] A preparation method of anti-bioadhesion superhydrophobic suspension, comprising the steps of:

[0036] (1) Preparation of nano-zinc oxide mixed solution: disperse 2.0 g of zinc oxide with a particle diameter of 30 nanometers and 2.0 g of zinc oxide with a particle diameter of 90 nanometers in 50 mL of absolute ethanol, then add 5 mL of deionized water dropwise, and stir Evenly, disperse with ultrasonic vibration at 40°C for 30 minutes to form the nano-zinc oxide mixture;

[0037](2) Dispersion modification of the nano-zinc oxide mixed solution: add 200 μL of γ-aminopropyltriethoxysilane (dispersion modifier) to the above-mentioned nano-zinc oxide mixed solution, and use a collector type constant temperature heating magnetic stirring Stir magnetically at a speed of 600rpm at 45°C for 1 hour to form a dispersed modified nano-zinc oxide mixture;

[0038] (3) Hydrophobic modification of the nano-zinc oxide mixed solution: Add 200 μL of perfluorooctyltrimethoxysilane (hy...

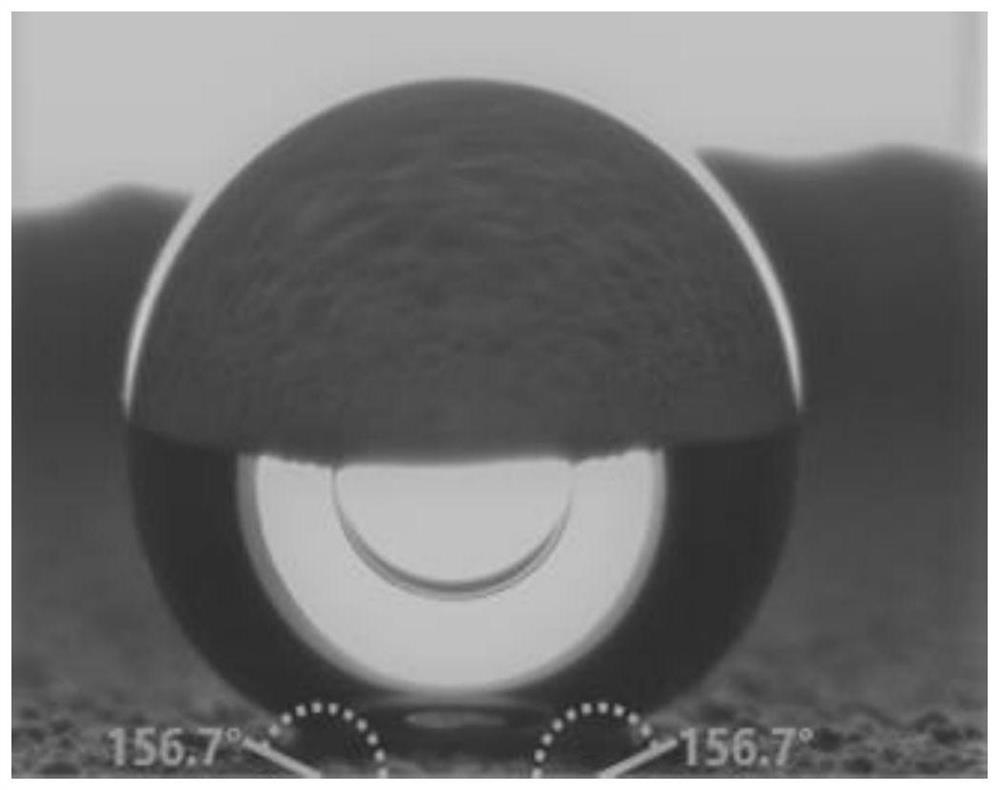

Embodiment 2

[0044] A preparation method of anti-bioadhesion superhydrophobic suspension, comprising the steps of:

[0045] (1) Preparation of nano-zinc oxide mixed solution: disperse 2.0 g of zinc oxide with a particle diameter of 30 nanometers and 1.0 g of zinc oxide with a particle diameter of 90 nanometers in 40 mL of absolute ethanol, then add 2 mL of deionized water dropwise, and stir Uniformly, disperse with ultrasonic vibration at 30°C for 25 minutes to form the nano-zinc oxide mixture;

[0046] (2) Dispersion modification of nano-zinc oxide mixed solution: add 100 μL of γ-aminopropyltriethoxysilane (dispersion modifier) to the above-mentioned nano-zinc oxide mixed solution, and use a water-bath magnetic stirrer at 35 ° C Under magnetic stirring at a speed of 800rpm for 2 hours, form a dispersed modified nano-zinc oxide mixed solution;

[0047] (3) Hydrophobic modification of the nano-zinc oxide mixed solution: Add 400 μL of perfluorooctyltrimethoxysilane (hydrophobic modifier) ...

Embodiment 3

[0053] A preparation method of anti-bioadhesion superhydrophobic suspension, comprising the steps of:

[0054] (1) Preparation of nano-zinc oxide mixed solution: disperse 2.5g of zinc oxide with a particle diameter of 30 nanometers and 2.5g of zinc oxide with a particle diameter of 90 nanometers in 60mL of absolute ethanol, then add 10mL of deionized water dropwise, and stir Evenly, disperse with ultrasonic vibration at 50°C for 30 minutes to form the nano-zinc oxide mixture;

[0055] (2) Dispersion modification of the nano-zinc oxide mixed solution: add 400 μL of γ-aminopropyltriethoxysilane (dispersion modifier) to the above-mentioned nano-zinc oxide mixed solution, and use a collector type constant temperature heating magnetic stirring The device was magnetically stirred at a speed of 500rpm at 45°C for 0.5 hours to form a dispersion-modified nano-zinc oxide mixed solution;

[0056] (3) Hydrophobic modification of the nano-zinc oxide mixed solution: add 100 μL of perfluo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com