Microminiature two-degree-of-freedom ultrasonic motor and driving method thereof

A technology of ultrasonic motor and driving method, which is applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., and can solve the problem of low noise, limiting the practical application development and structure of micro ultrasonic motor complex design issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The details of the present invention and the specific embodiments of the present invention will be further described below with reference to the accompanying drawings.

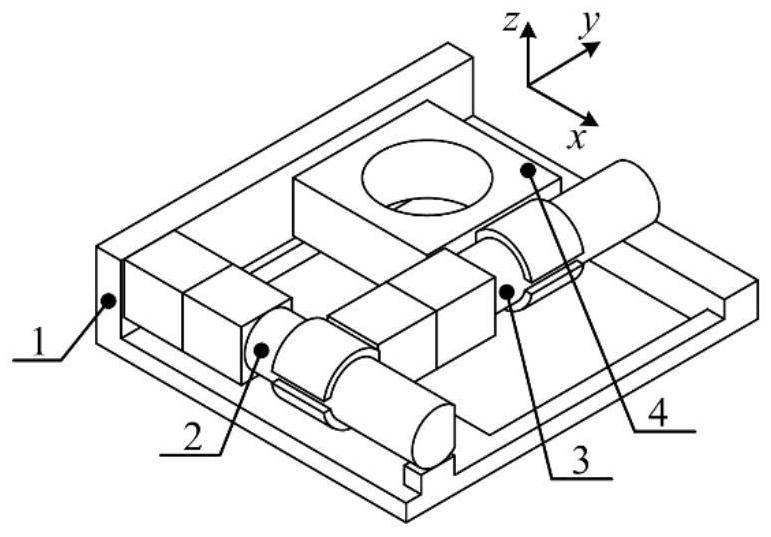

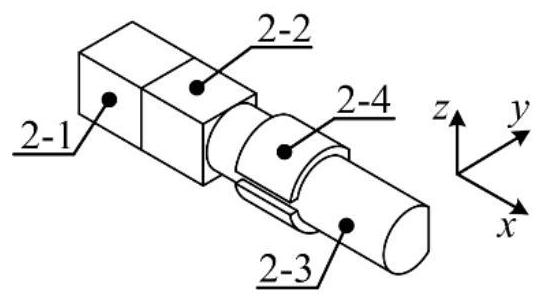

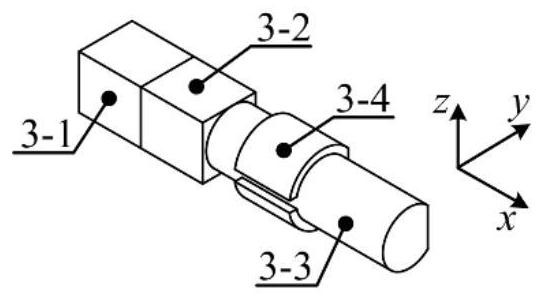

[0020] See Figure 1 to 4 As shown, a small two-degree-of-freedom ultrasonic motor is characterized in that the base 1, the X-axis moving unit 2, the Y-axis moving unit 3, and the stage 4; the X-axis moving unit 2 passes The stack A2-1 is fixed to the base 1; the Y-axis moving unit 3 is fixedly attached to the driven parts A2-4 of the X-axis moving unit 2 by a piezoelectric stack C3-1; The stage 4 is fixed to the slave B3-4 of the Y-axis moving unit 3; the stage 4 can be formed into an external rectangle, an interior hollow ring structure to mount a micro camera, and a micro camera Small two-degree-of-freedom ultrasound motors are set to mobile phones, drones, etc., which can realize imaginative functions.

[0021] The base 1 is composed of a boss A1-1, a hollow cavity 1-2, a boss B1-3, and the action of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com