Optimum control method and system for temperature drop rate of lining concrete

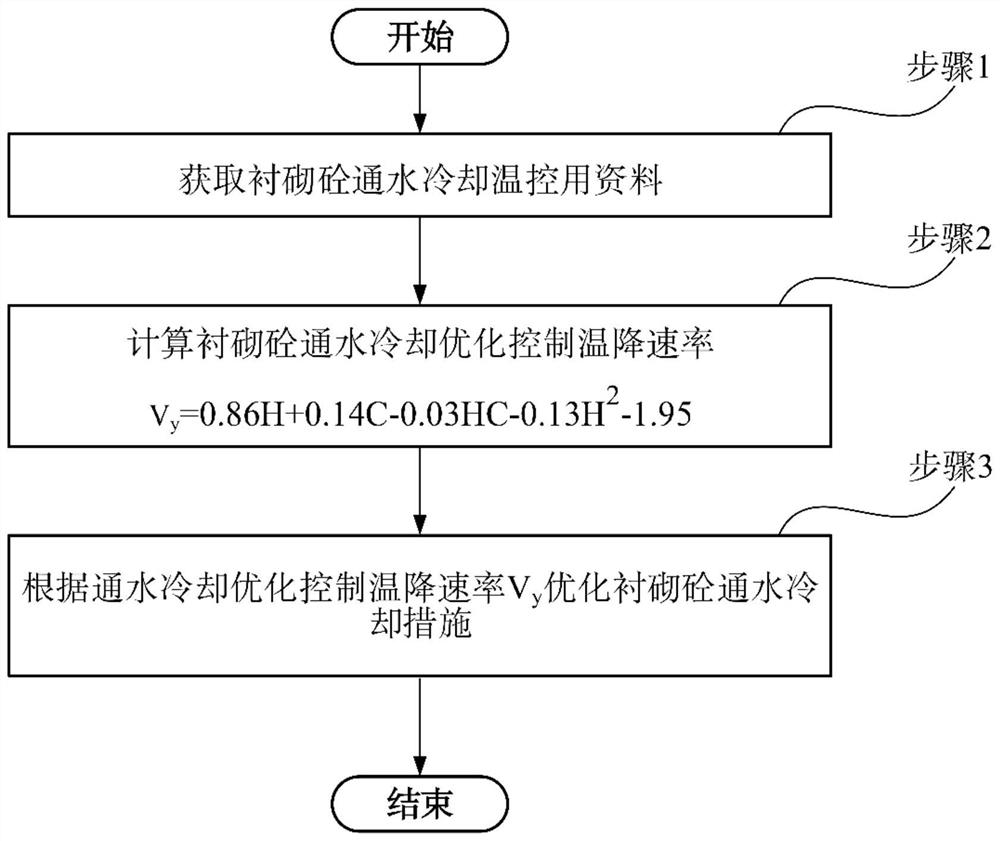

A technology of optimization control and rate reduction, applied in the direction of design optimization/simulation, calculation, computer-aided design, etc., can solve problems such as water cooling without calculation, and achieve the effect of ensuring temperature control and anti-cracking, scientific and good temperature The effect of controlling the anti-cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

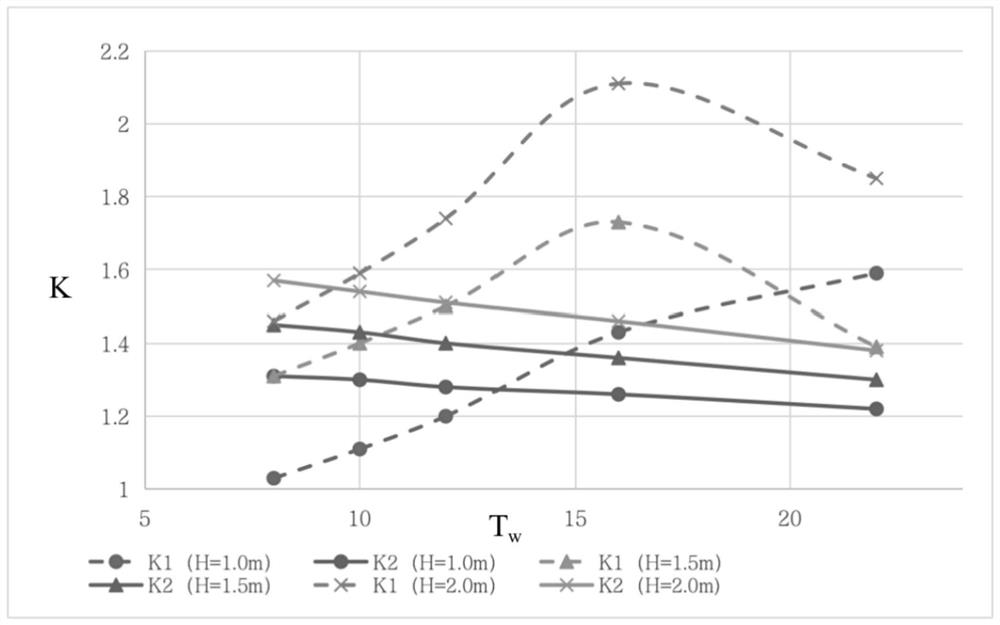

Method used

Image

Examples

Embodiment Construction

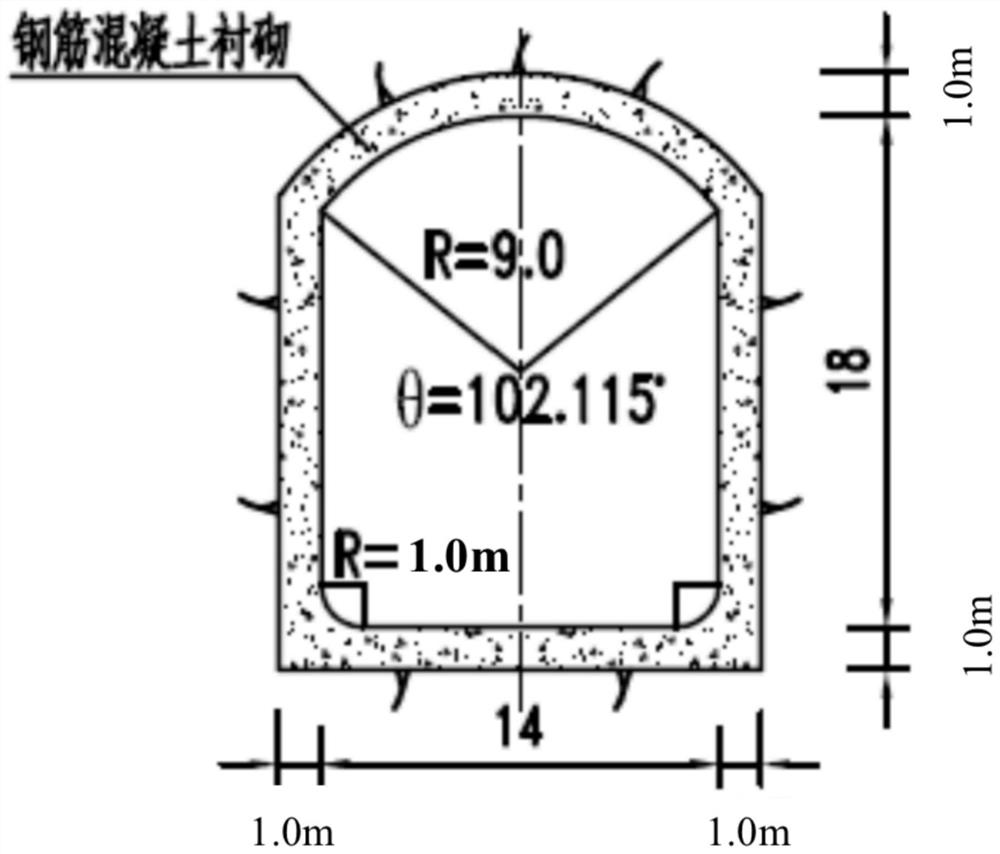

[0045] Hereinafter, with reference to the accompanying drawings, taking the lining concrete of the flood discharge tunnel of Wudongde Hydropower Station as an example, the specific implementation scheme of the method and system for optimizing the temperature drop rate of the lining concrete involved in the present invention will be described in detail.

[0046]

[0047] Wudongde Hydropower Station is mainly used for power generation, taking into account the functions of flood control, shipping and sand retention. The installed capacity of the power station is 10200MW. The dam is a concrete double-curvature arch dam, and the flood discharge adopts the main flood discharge of the dam body, supplemented by the flood discharge tunnel on the bank. The three flood discharge tunnels all adopt a pressure tunnel followed by a door tunnel, which is composed of a water inlet, a pressure tunnel section, a working gate room, a non-pressure tunnel section, an exit section, and an energy d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com