Lining concrete temperature drop rate optimization control method and system

An optimized control and rate reduction technology, applied in design optimization/simulation, special data processing applications, computer-aided design, etc., can solve problems such as uncalculated water cooling, to ensure the effect of temperature control and anti-cracking, strong scientific , Good temperature control and anti-cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

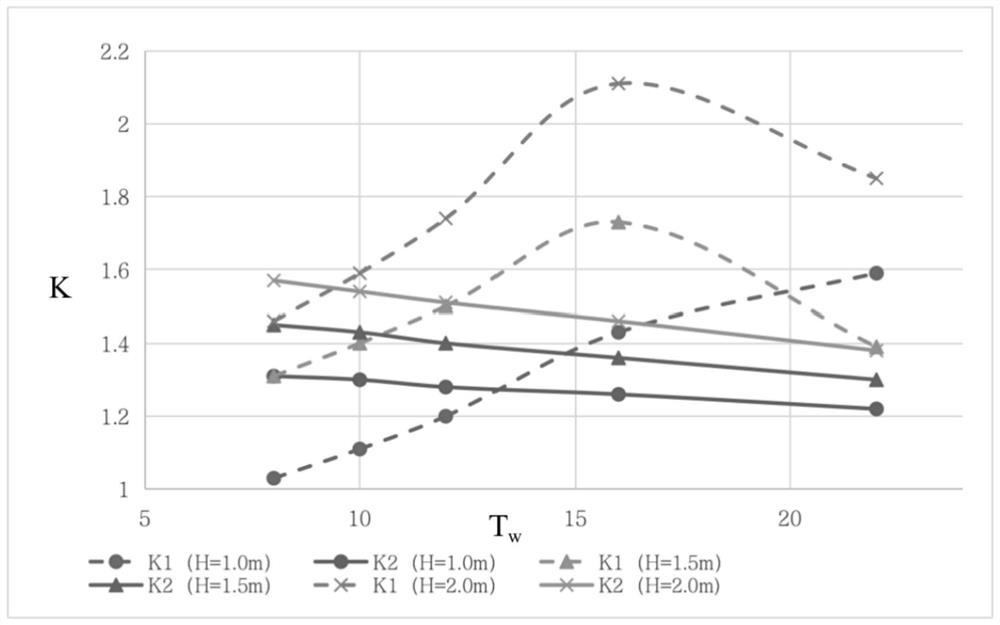

[0059] 3 # Calculation of Optimal Temperature Drop Rate for Concrete Water Cooling Control in No.1 Warehouse Roof Arch Lining in No-pressure Section

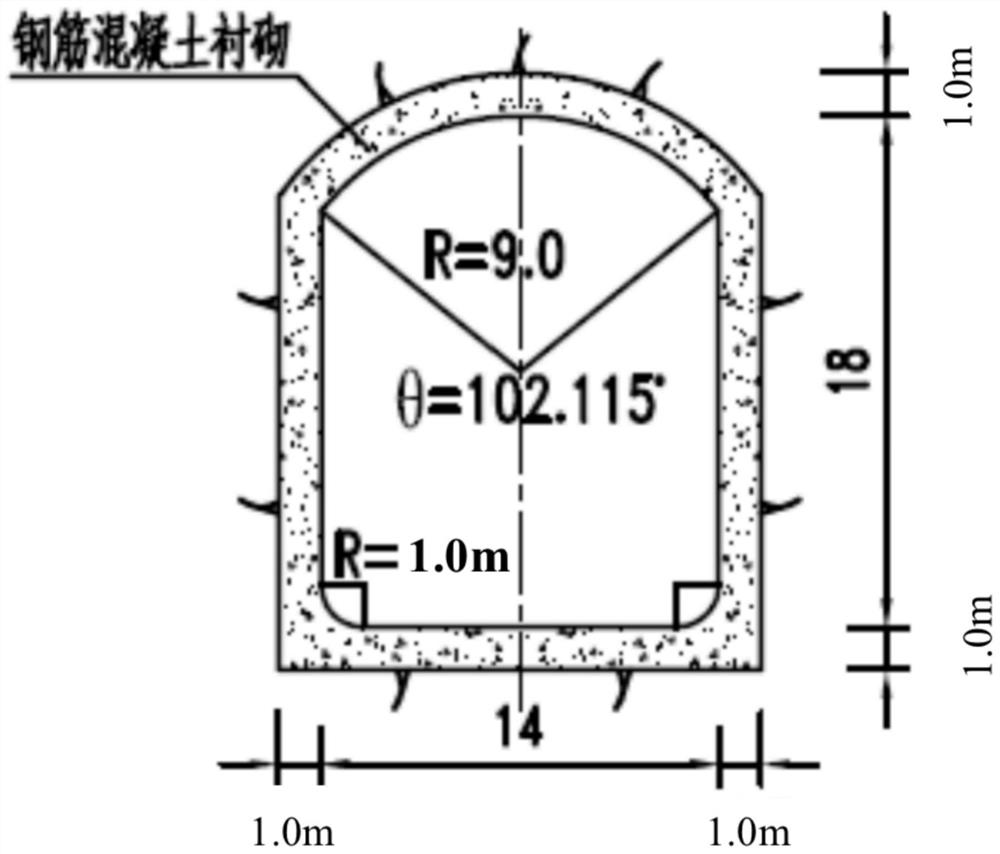

[0060] 3 # The first storehouse of the unpressurized section of the tunnel, the gate-shaped lining, the thickness of the side wall lining is 0.8m, and the circumferential construction joints are set every 9m along the axis of the flood discharge tunnel, the surrounding rock is class II, and the bottom plate and side wall of the lining structure are C 90 40 Concrete, top arch C 90 30W8F150 concrete, such as Figure 5 shown. The concrete is poured in two phases: first the side arch, and then the floor. Will be poured in May. Here we introduce the calculation of the optimal temperature drop rate for side-roof arch lining concrete pouring water cooling control. The basic temperature control information is the same as above. Use normal temperature tap water for moisturizing and curing for 28 days, and water cooling to control...

Embodiment 2

[0071] 3 # Calculation of Optimal Temperature Drop Rate for Concrete Lining of Side Wall of No.22 Warehouse in No-pressure Section of Cavern by Water Cooling Control

[0072] 3 # The 22nd storehouse in the unpressurized section of the tunnel, the gate-shaped lining, the thickness of the side wall lining is 1.5m, and the circumferential construction joints are set every 9m along the axis of the flood discharge tunnel. 90 40 Concrete, top arch C 90 30W8F150, such as Figure 7 shown. The concrete is poured in two phases: first the side arch, and then the floor. Will be poured in September. Here we introduce the calculation of the optimal temperature drop rate for side-roof arch lining concrete pouring water cooling control. The basic temperature control information is the same as above. Use normal temperature tap water for moisturizing and curing for 28 days, and water cooling to control the internal temperature of the concrete.

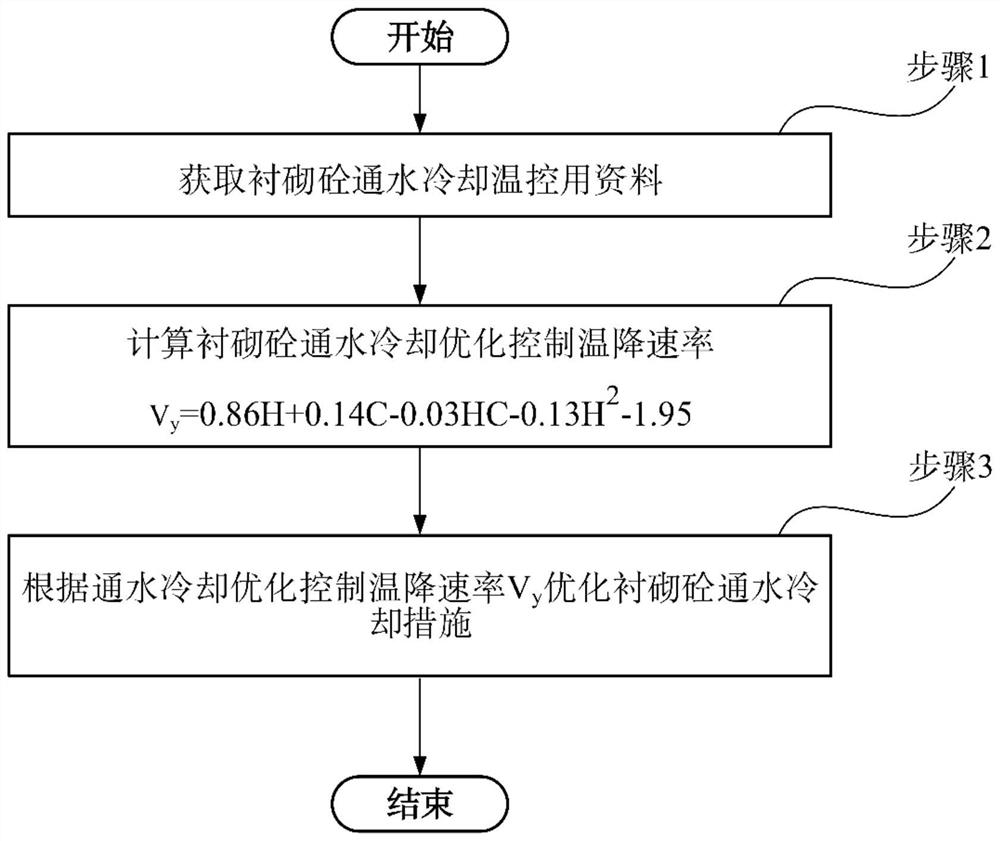

[0073] like figure 2 As shown, the opti...

Embodiment 3

[0084] Optimal control system for temperature drop rate of lining concrete

[0085] This embodiment provides a system capable of automatically implementing the above method for optimal control of the temperature drop rate of lining concrete. The system includes: an input display unit, a storage unit, a calculation unit, a water cooling unit, and a control unit.

[0086] The input and display part is used for allowing the operator to input the collected data for temperature control of lining concrete through water cooling according to the prompt, and can perform corresponding display according to the operation instruction input by the operator. For example, the input and display unit can optimize the temperature drop rate V calculated by the calculation unit for cooling through water according to the operation instruction. y The display can also display the water cooling measures performed by the water cooling unit according to the operation instructions.

[0087] The storage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com