Intelligent self-checking electro-hydraulic servo valve

An electro-hydraulic servo valve, servo valve technology, applied in the direction of servo motor components, valve details, multi-way valves, etc., can solve the problems of no oil pressure self-adaptation, lack of valve core usage status monitoring function, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

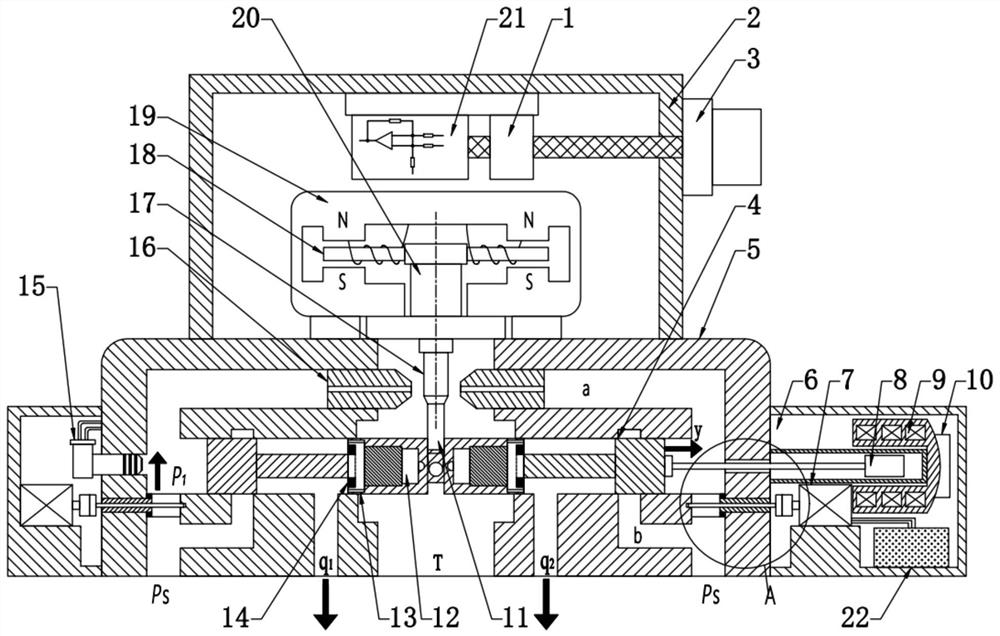

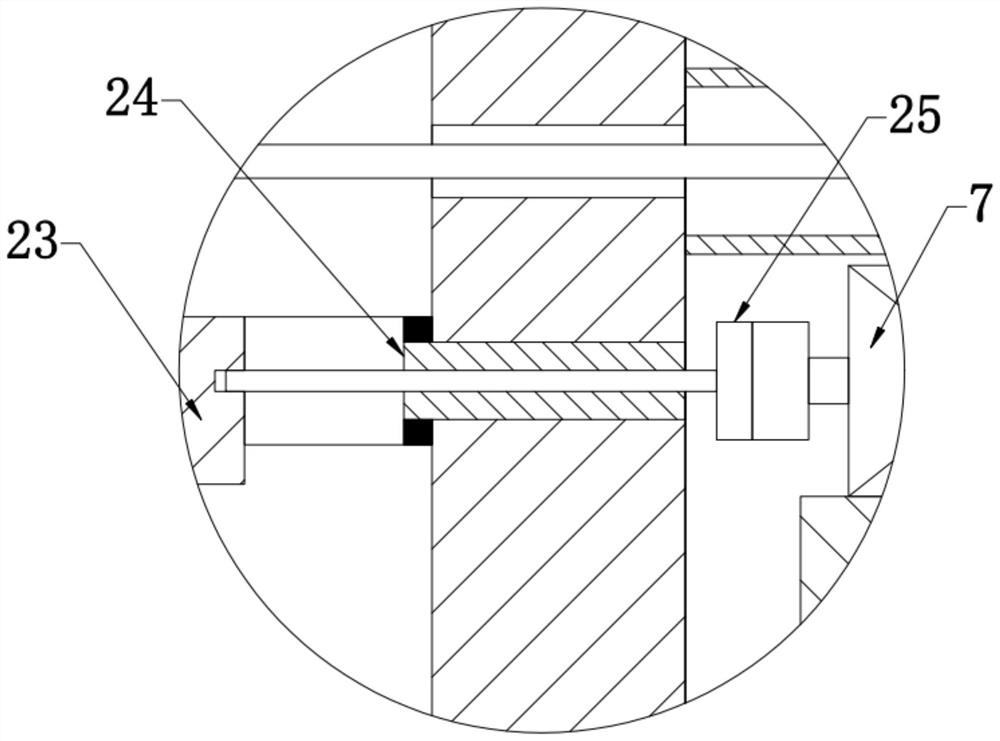

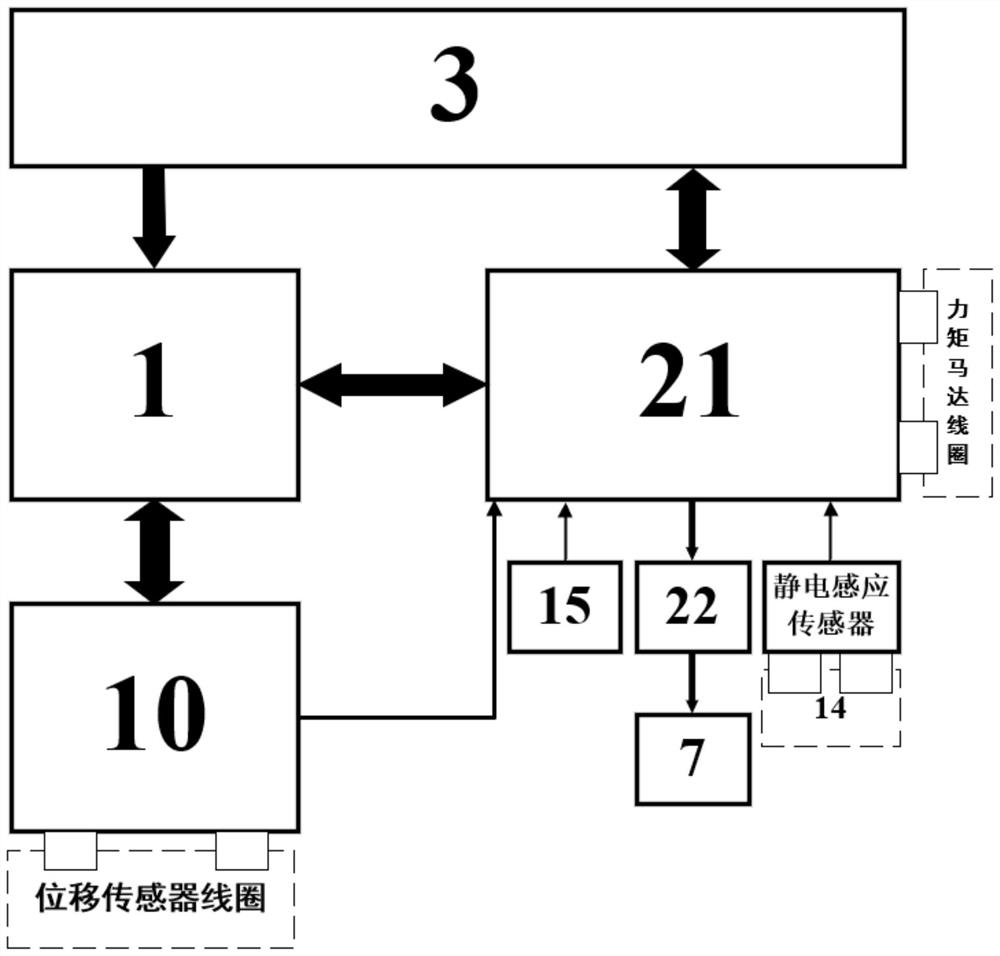

[0018] Such as figure 1As shown, an intelligent self-test electro-hydraulic servo valve includes a valve body 5, an upper shell 2, a torque motor 19, an armature 18, a servo valve controller 21, a double nozzle baffle 17, a pressure transmitter 15, and a feedback rod 11 , LVDT displacement sensor 9, displacement sensor circuit 10, slide valve assembly and orifice opening adjustment assembly; upper casing 2 and valve body 5 are fixed; servo valve controller 21 is fixed in upper casing 2; torque motor 19 is placed in upper casing 2, and fixed with the valve body 5, controlled by the servo valve controller 21; one end of the double nozzle baffle 17 is fixed with the spring tube 20, and the other end is fixed with the end of the feedback rod 11; the armature 18 is set on the two ends of the torque motor 19 Inside the armature coil; the spring tube 20 is fixed to the middle of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com