Miniature roller bit suitable for indoor micro-drilling test in oil and gas drilling industry

A technology for oil and gas drilling and roller cone bits, which is applied in drill bits, drilling equipment, earth-moving drilling, etc., and can solve the problems of core waste, bottom hole pattern change, and low effective drilling depth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

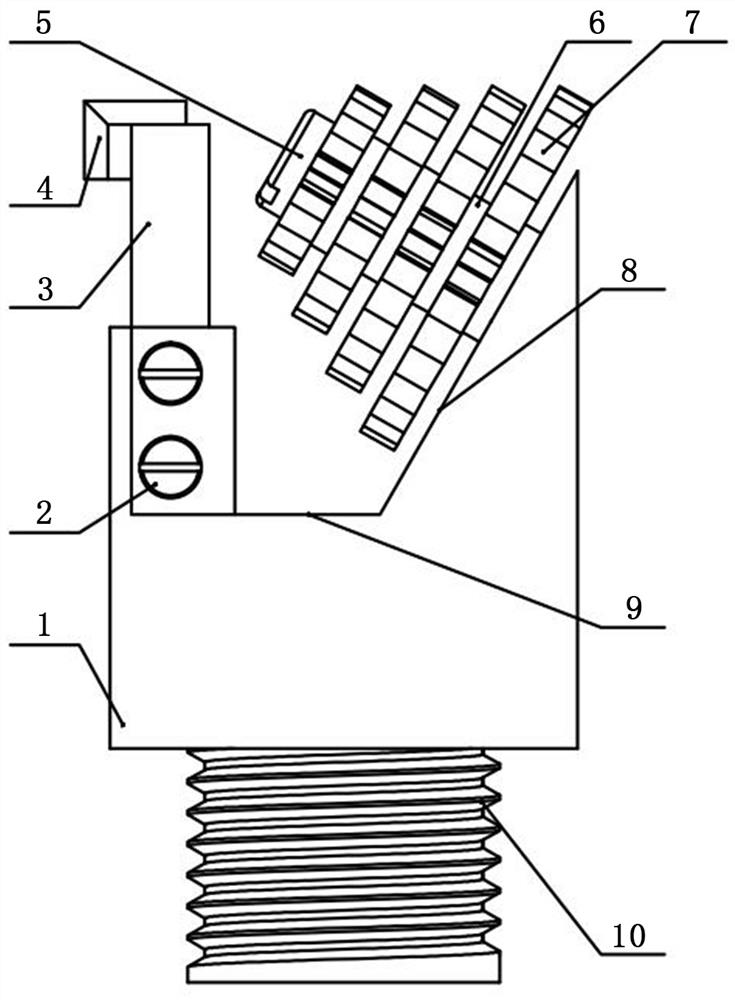

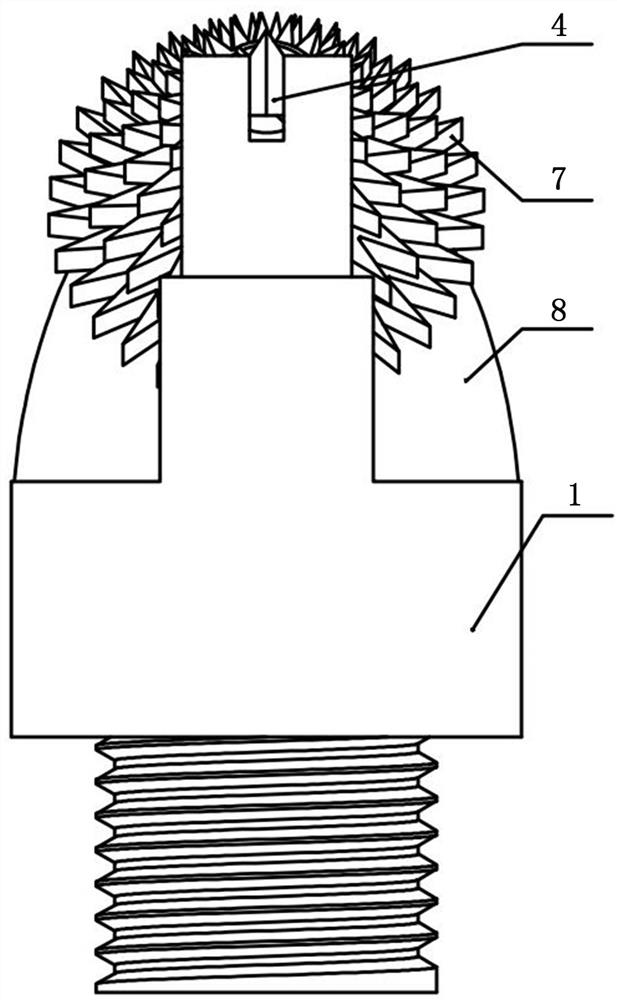

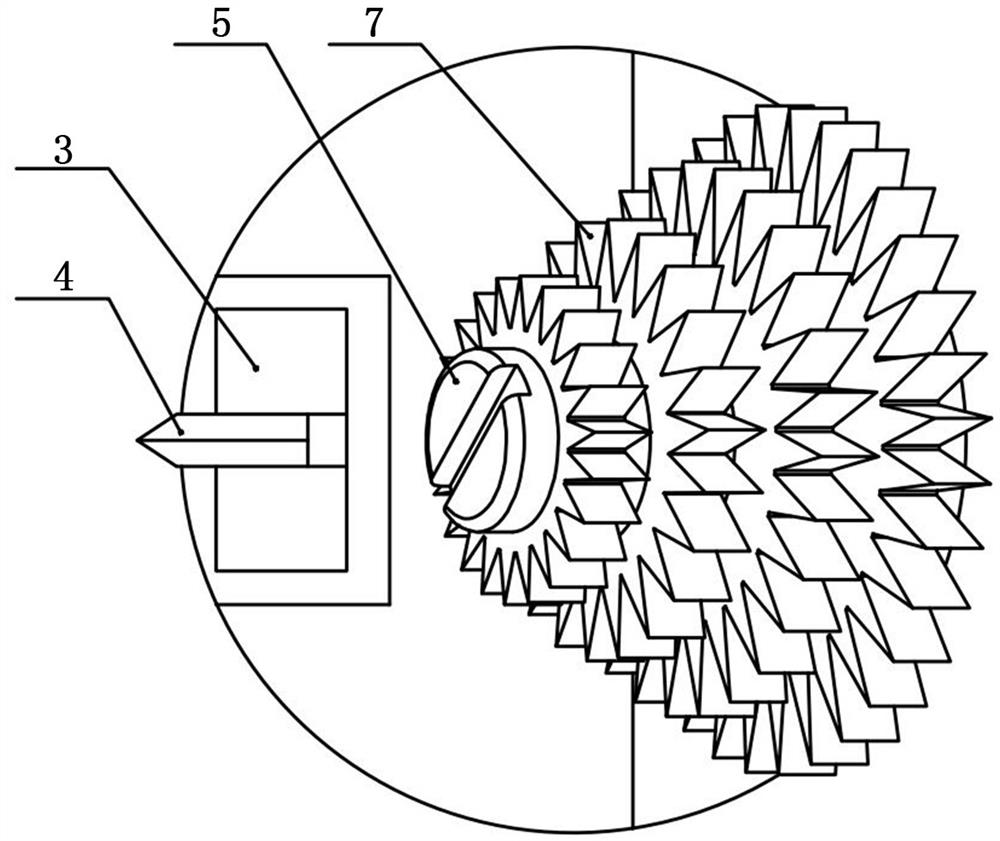

[0022] Such as Figure 1-Figure 4 As shown, a micro-cone bit suitable for indoor micro-drilling tests in the oil and gas drilling industry includes a bit seat 1, which is a cylinder with an appropriate diameter and height, and the drilling surface of the bit seat 1 is composed of an inclined surface 8 Constituted with a horizontal plane 9; a cone shaft 5 is fixed on the inclined plane 8, and the cone shaft 5 is perpendicular to the inclined plane 8, and a cone is installed on the cone shaft 5; an extension rod 3 is fixed on the horizontal plane 9, The extension rod 3 is connected with a gauge tooth 4, and the gauge tooth 4 is processed and formed using an alloy material with high hardness and high wear resistance. The diameter does not change.

[0023] As an optional embodiment, the cone includes four cutting blades 7 with unequal cutting radii, and the cutting blades 7 are all installed on the cone shaft 5, and the cutting blades 7 are laminated, which is convenient for the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com