Multi-layer lifting and transverse-moving garage based on comb tooth parking robot and using method

A lifting and traversing, robot technology, which is applied to the buildings, building types, buildings, etc. where cars are parked, can solve the problems of low utilization rate of the lifting and traversing three-dimensional garage, the need for special personnel to manage, and the inapplicability of comb-type parking robots.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

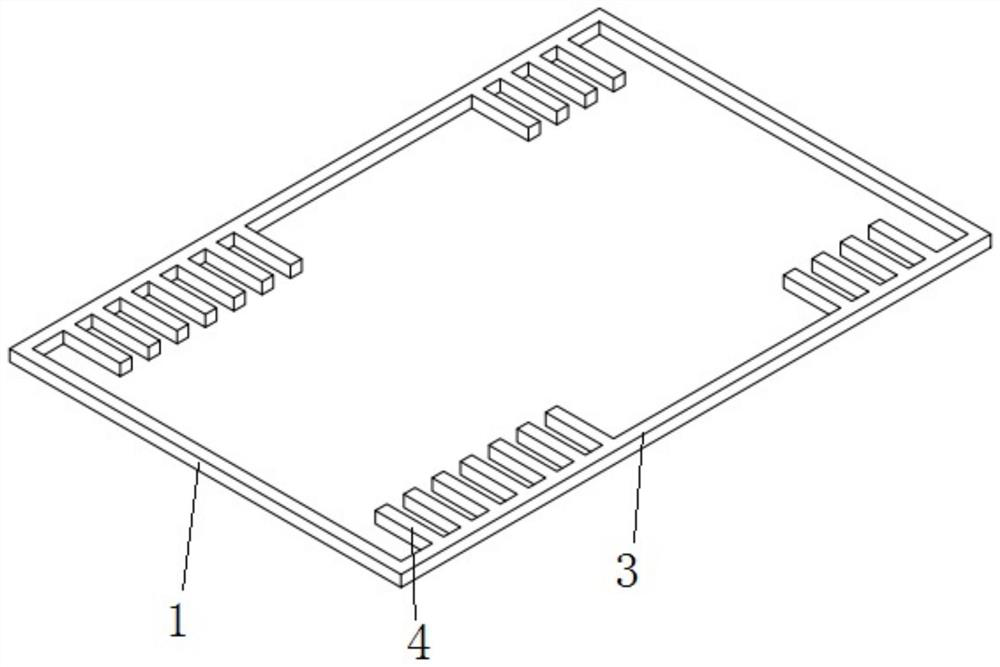

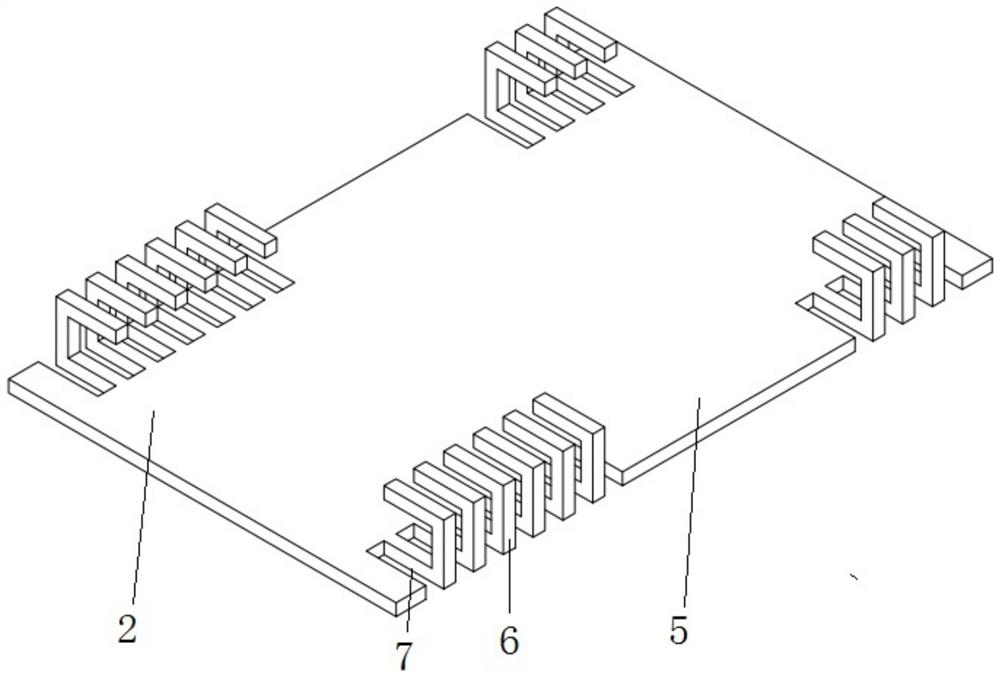

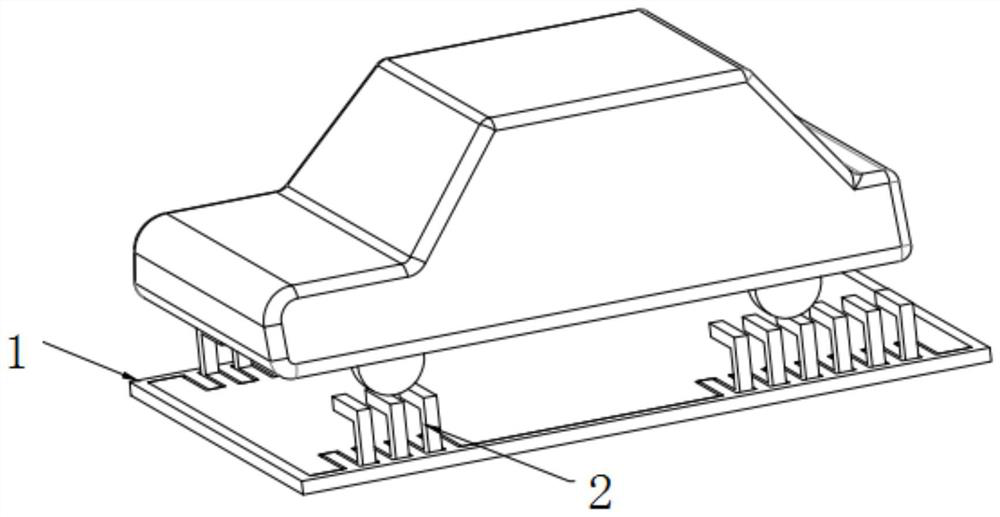

[0044] This embodiment relates to a multi-storey lifting and traversing garage based on a comb-toothed parking robot, such as Figure 1-5 As shown, the multi-storey lifting and traversing garage can park three layers of vehicles, including a frame 8, a bottom parking frame 9, an intermediate layer parking frame 10 and a top floor parking frame 13. Described bottom parking frame 9 is the fixed comb frame 2 that is fixedly installed on the parking space of low floor. The top floor parking frame 13 is installed on the top of the frame 8 and includes a movable comb frame 1 and a lifting device 12 thereof. Described middle floor parking rack comprises traversing device 11, movable comb rack 1 and lifting device 12, wherein, the lifting device 12 of movable comb rack 1 is installed on the traversing device 11, and is connected with movable comb rack 1. 1 connected. The racks 4 of the movable comb frame 1 and the fixed racks 6 of the fixed comb frame 2 are arranged alternately. Th...

Embodiment 2

[0070] This embodiment relates to a double-deck lift garage suitable for a comb-toothed parking robot. The difference between the double-storey lifting garage in this embodiment and the three-story lifting and traversing garage in Embodiment 1 is that the three-story lifting and traversing garage in this embodiment also includes a temporary parking comb rack. The temporary parking comb frame is a mobile comb frame driven by a steering wheel and is located outside the frame.

[0071] This embodiment also relates to the method for accessing and withdrawing vehicles in the above-mentioned three-story lifting and traversing garage. The difference between the car access method in this embodiment and the car access method in Embodiment 1 lies in steps S4 and S9. Step S4 in this embodiment is: the comb-toothed parking robot transports other vehicles on the corresponding bottom parking rack to the parking exchange position of the unparked vehicle, the unoccupied bottom parking rack o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com