Alginate fiber blended fabric and dyeing method thereof

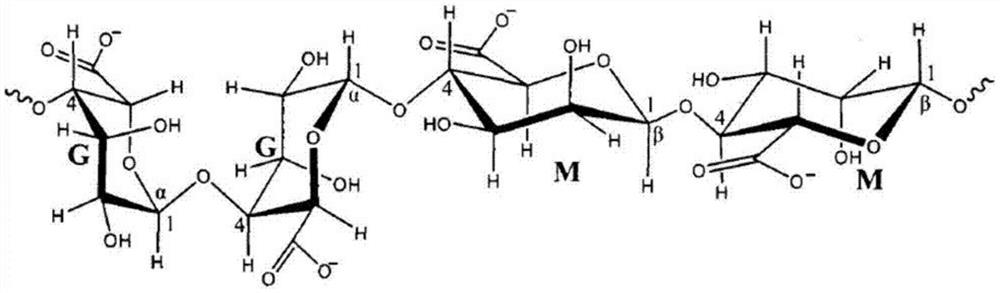

A technology of seaweed fiber and blended fabrics, which is applied in dyeing, textiles and papermaking, and can solve problems such as difficult dyeing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

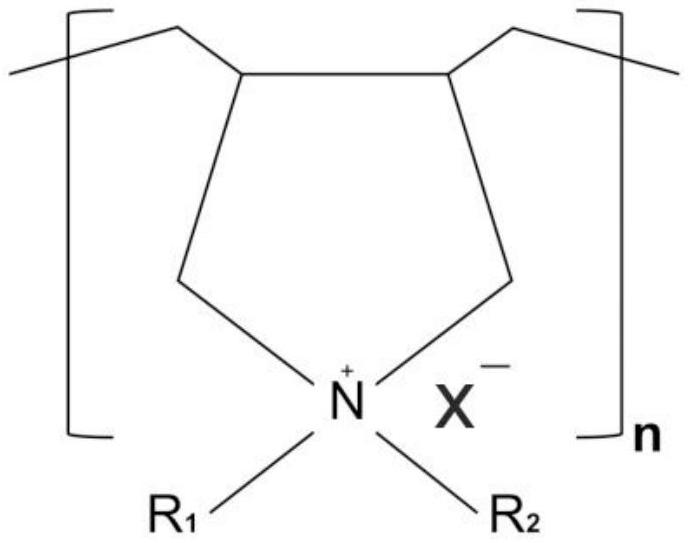

[0117] Prepare an aqueous solution of five-membered ring quaternary ammonium salt polymer with a mass percent concentration of 10% as a treatment solution, and add it to the pretreatment bath according to 2% of the weight of the seaweed fiber blended fabric, and the bath ratio of the pretreatment bath is 1:15. Put the seaweed fiber / cotton blended fabric to be dyed into the above pretreatment solution, shake it at 30°C for 10 minutes, and then rinse the pretreated fabric with water at 30°C for 5 minutes.

[0118] Weigh direct scarlet 4BS as a dye according to 2% of the weight of the seaweed fiber / cotton blended fabric, weigh distilled water according to a bath ratio of 1:30, and add the weighed direct dye to distilled water to prepare a dye liquor. Dyeing at room temperature, heating up to 80°C at a rate of 1°C / min, and dyeing for 60 minutes. Then soak the dyed seaweed fiber / cotton blended fabric in a neutral detergent with a concentration of 5g / l, shake it at 90°C for 10 minut...

Embodiment 2

[0120] Prepare an aqueous solution of five-membered ring quaternary ammonium salt polymer with a mass percent concentration of 10% as a treatment solution, and add it to the pretreatment bath according to 5% of the weight of the seaweed fiber blended fabric, and the bath ratio of the pretreatment bath is 1:15. Put the seaweed fiber / cotton blended fabric to be dyed into the above pretreatment solution, shake it at 30°C for 10 minutes, and then rinse the pretreated seaweed fiber blended fabric with 30°C water for 5 minutes.

[0121] Weigh direct yellow RS as a dye according to 3% of the weight of the seaweed fiber / cotton blended fabric, weigh distilled water according to a bath ratio of 1:30, and add the weighed direct dye to distilled water to prepare a dye liquor. Dyeing at room temperature, heating up to 80°C at a rate of 1°C / min, and dyeing for 60 minutes. Soak the dyed seaweed fiber / cotton blended fabric in a neutral detergent with a concentration of 5g / l, shake it at 90°C ...

Embodiment 3

[0123] Prepare a five-membered ring quaternary ammonium salt polymer aqueous solution with a concentration of 10% by mass as a treatment solution, and add it to the pretreatment bath according to 7% of the weight of the seaweed fiber blended fabric, and the bath ratio of the pretreatment bath is 1:15. Put the seaweed fiber / cotton blended fabric to be dyed into the above pretreatment solution, shake it at 30°C for 10 minutes, and then rinse the pretreated seaweed fiber blended fabric with 30°C water for 5 minutes.

[0124] Weigh direct blue 3RL as a dye according to 4% of the weight of the seaweed fiber / cotton blended fabric, weigh distilled water according to a bath ratio of 1:30, and add the weighed direct dye to distilled water to prepare a dye liquor. Dyeing at room temperature, heating up to 80°C at a rate of 1°C / min, and dyeing for 60 minutes. Soak the dyed seaweed fiber / cotton blended fabric in a neutral detergent with a concentration of 5g / l, shake it at 90°C for 10 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| soaping fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com