A kind of water-resistant plastering mortar and preparation method thereof

A plastering mortar and water-resistant technology, applied in the field of mortar materials, can solve the problems of reduced compressive strength and poor durability, and achieve the effects of improved strength, improved water resistance, and good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

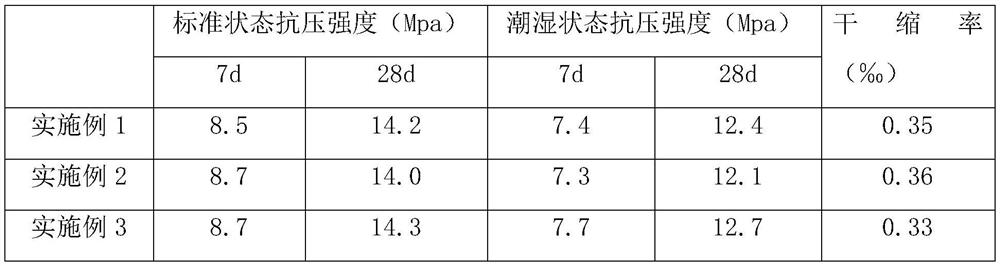

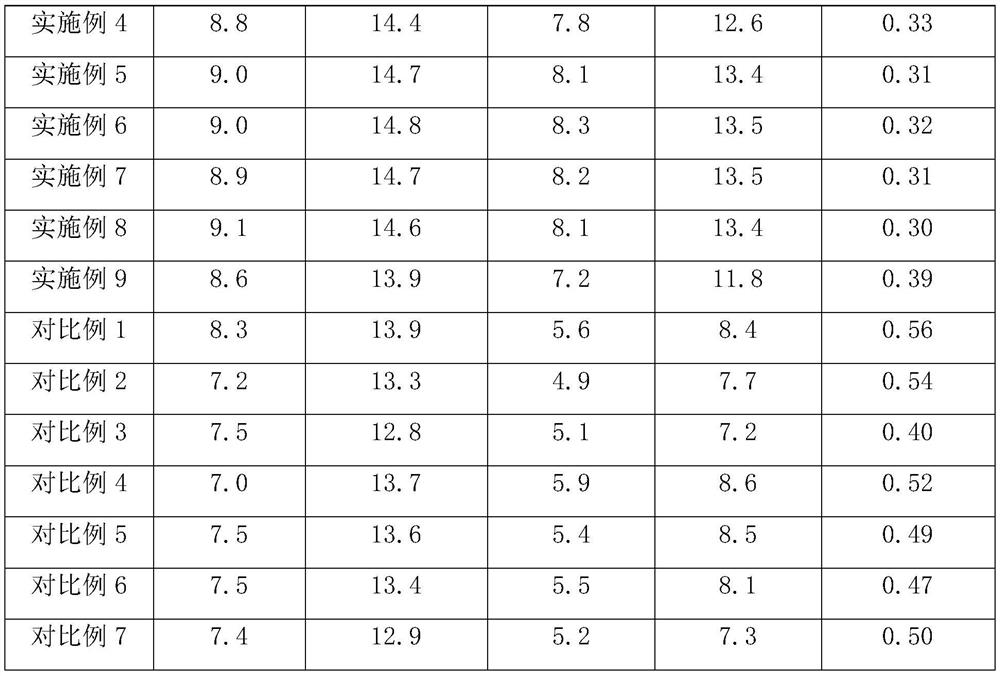

Examples

Embodiment 1-5

[0055] S1, the polyacrylic acid of 10.5kg, the tributyl phosphate of 3kg and the hydroxypropyl methylcellulose of 3.6kg are mixed, and the mass ratio of polyacrylic acid, tributyl phosphate, hydroxypropyl methylcellulose is 3.5: 1:1.2, the stirring speed is 120r / min, the temperature is raised to 65°C during the stirring process and the temperature is kept constant for 45min to obtain the microcapsule core liquid;

[0056] S2, take 9kg of microcapsule core liquid and mix with 5kg of diatomite, that is, the mass ratio of diatomite to mortar microcapsule core liquid is 1:1.8, mix and stir for 20min at a stirring speed of 120r / min, mix well and place 18h, obtain microcapsules;

[0057] S3. Mix epoxy resin, plasticizer and microcapsules in the amount shown in Table 2, and mix and stir for 15min at a stirring speed of 120r / min to obtain a microcapsule mixture;

[0058] S4. Add cement, aluminosilicate zeolite powder, admixture and half of the water to the microcapsule mixture, and m...

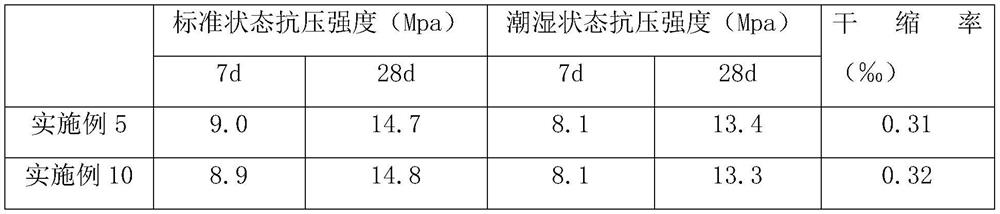

Embodiment 6

[0064] The difference from Example 5 is only that: 13.8 kg of microcapsule core liquid is mixed with 6 kg of diatomite, that is, the mass ratio of diatomite to microcapsule core liquid is 1:2.3 to obtain microcapsules.

Embodiment 7

[0066] The only difference from Example 5 is: 11kg of polyacrylic acid, 2kg of tributyl phosphate and 3.4kg of hydroxypropyl methylcellulose are mixed, that is, polyacrylic acid, tributyl phosphate, hydroxypropyl methylcellulose The mass ratio was 5.5:1:1.7, and the microcapsule core liquid was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com