Plate edge thermal cutting process and device in production of ultra-thin float glass

A technology of float glass and cutting process, applied in the field of ultra-thin float glass, which can solve the problems of annealing of ultra-thin glass and low pass rate of cut finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

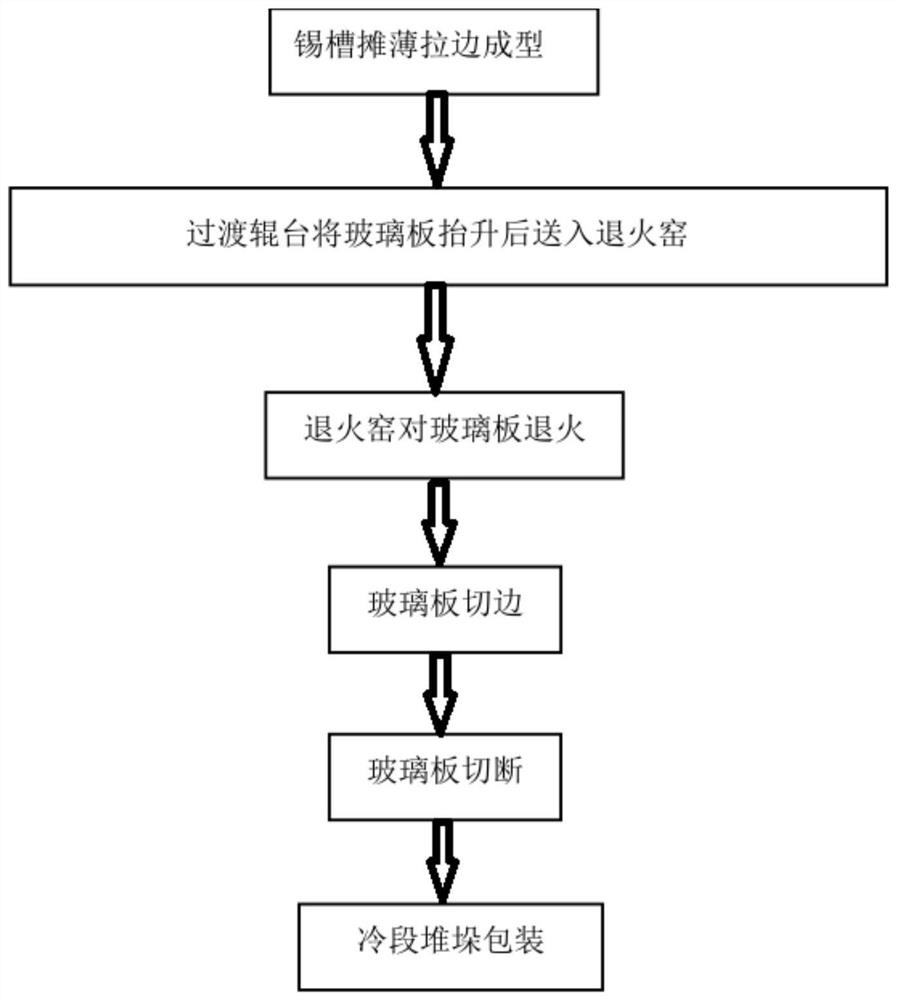

[0040] Such as figure 1 As shown, the above background technology has mentioned that the traditional production process of ultra-thin float glass, the steps are as follows:

[0041] Step 1: Mix quartz sand powder and sodium carbonate powder evenly, heat at high temperature, smelt into glass water, and then add calcium carbonate;

[0042] Step 2: Pour the liquid glass water into the tin liquid surface in the tin bath to dilute it naturally. After the glass water cools down, it will be in the shape of a glass plate. It will be pulled outward by the edge pulling machine at the edge of the glass plate or formed by itself in the middle of the glass plate. The outward expansion tension makes the middle of the glass sheet thinner and the edge of the glass sheet thicker;

[0043] Step 3: The glass plate formed in the tin bath is first sent to the annealing kiln for annealing through the transition roller table, and then the annealed glass plate is taken out of the annealing kiln.

[0...

Embodiment 2

[0047] Such as Figure 4 , 5 As shown, the shaped glass plate 6 is divided into a glass plate edge portion 61 and a glass plate middle portion 62 (glass plate after trimming), the thickness of the glass plate edge portion 61 is within the range of 5mm, and the thickness of the glass plate middle portion 62 is Below 1 mm, the thickness of the glass plate middle part 62 is 0.3 mm, and the present invention mainly makes the glass plate edge part 61 on the glass plate 6 and the glass plate middle part 62 separate and carry out the cutting.

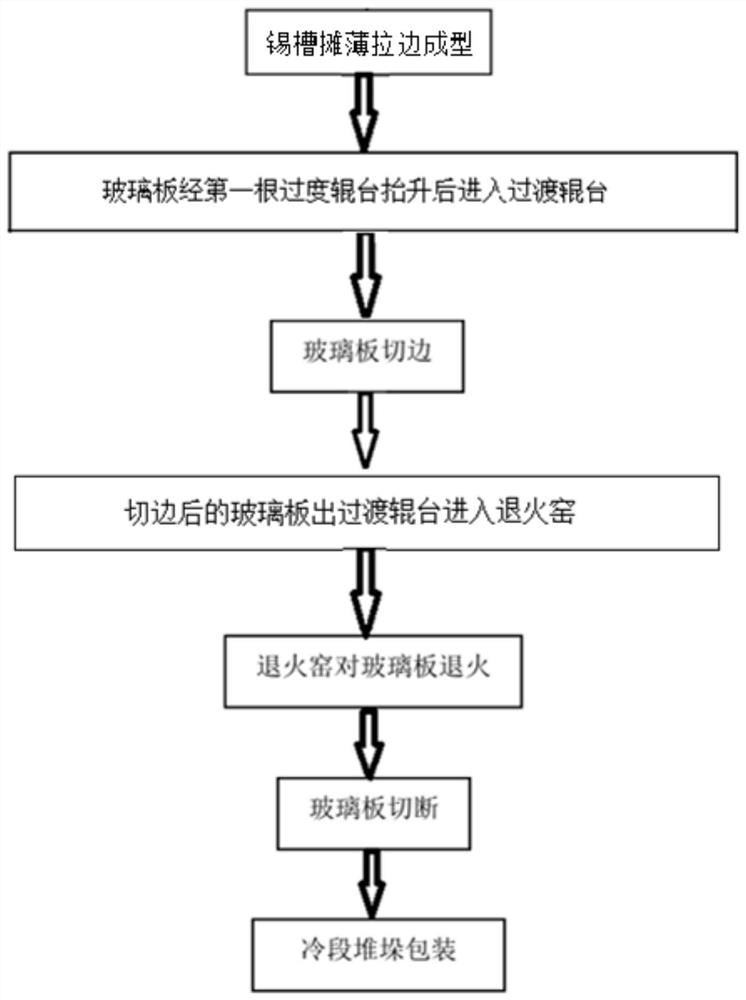

[0048] Such as figure 2 As shown, the present embodiment is a preferred embodiment, which provides a plate edge thermal cutting process in the production of ultra-thin float glass, including the following steps:

[0049] Step S101: passing the thinned shaped glass sheet 6 through the first transition roller 4 of the transition roller table 7 in the tin bath 5, elevating the shaped glass sheet 6 and sending it into the transition roller tabl...

Embodiment 3

[0063] Such as Figure 3-4 As shown, the present embodiment provides a plate edge thermal cutting process device in the production of ultra-thin float glass, including a liquid-cooled cutting device 2, a tin bath 5, a transition roller table 7 and an annealing kiln 8, and the transition roller table 7 has The first transition roller 4, transmission roller 3 and lehr 8 have an annealing kiln transmission roller 1 (the number of the annealing kiln transmission roller 1 is many), and the annealing kiln 8 is positioned at the front side of the transition roller table 7, and the tin tank 5 is located at The rear side of the transition roller table 7, the left and right sides of the transition roller table 7 or the left and right sides of the annealing kiln 8 are hung with a liquid-cooled cutting device 2 (not specifically shown), and the liquid-cooled cutting device 2 is connected or hung on the On the hanger or slide rail (not shown in the figure), the liquid-cooled cutting device...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com