Deviation rectifying method and equipment for amorphous strip processing device

A technology for amorphous strips and processing devices, which is applied in winding strips, transportation and packaging, thin material processing, etc., and can solve problems such as low deviation correction accuracy, high cost, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A deviation correction method for an amorphous strip processing device, the method comprising a sensor for monitoring the deviation of the amorphous strip and a deviation correction roller 1, the deviation correction roller 1 is arranged above or below the amorphous strip, and the deviation correction roller 1 There are two sets of rectifying components 4, which are respectively close to the two sides of the amorphous strip. The rectifying component 4 can press down or lift up the amorphous strip. When the sensor monitors the deflection of the amorphous strip, the deflection direction will The deviation correcting component 4 presses down or lifts up the amorphous strip, and after the amorphous strip is reset again, the deviation correcting component 4 resets.

[0025] When the length of the deflection or jack-up of the correction component 4 reaches the set distance based on the offset, based on the sensor monitoring the change of the offset of the amorphous strip, the ...

Embodiment 2

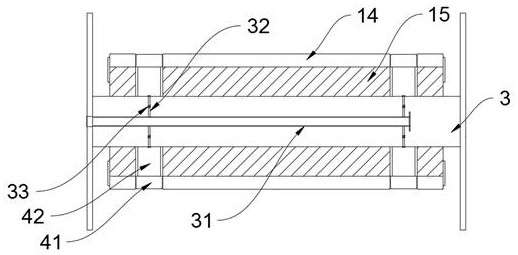

[0030] Such as Figure 1-3 As shown, a deviation correction device for an amorphous strip processing device includes a bracket 2 and a deviation sensor. The deviation correction roller 1 is connected to the inside of the bracket 2, and the deviation correction roller 1 includes a main roller 11 and an auxiliary roller. 12. A deviation correction assembly 4 is provided between the main roller 11 and the auxiliary roller 12, and the deviation correction assembly 4 may protrude from the upper end plane of the main roller 11 and the auxiliary roller 12.

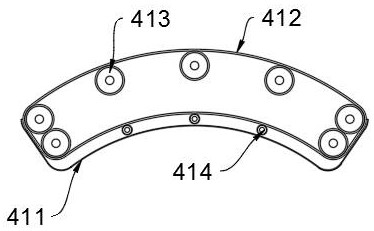

[0031] The deviation correction assembly 4 includes at least one set of arc-shaped top plates 41 , and the deviation correction assembly 4 includes a telescopic device, which drives the arc-shaped top plates 41 to protrude or retract into the surface of the deviation correction roller 1 . The telescopic device includes an outer pipe 42 and an inner rod 43, one end of the inner rod 43 is fixedly connected to the arc top plate 41, ...

Embodiment 3

[0036] Such as Figure 1-3 As shown, a deviation correction device for an amorphous strip processing device includes a bracket 2 and a deviation sensor. The deviation correction roller 1 is connected to the inside of the bracket 2, and the deviation correction roller 1 includes a main roller 11 and an auxiliary roller. 12. A deviation correction assembly 4 is provided between the main roller 11 and the auxiliary roller 12, and the deviation correction assembly 4 may protrude from the upper end plane of the main roller 11 and the auxiliary roller 12.

[0037] The deviation correction assembly 4 includes at least one set of arc-shaped top plates 41 , and the deviation correction assembly 4 includes a telescopic device, which drives the arc-shaped top plates 41 to protrude or retract into the surface of the deviation correction roller 1 . The telescopic device includes an outer pipe 42 and an inner rod 43, one end of the inner rod 43 is fixedly connected to the arc top plate 41, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com