Control device for paper printing or film laminating

A control device and lamination technology, which can be applied to general parts of printing machinery, printing, printing machines, etc., and can solve problems such as being easily touched by mistake.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

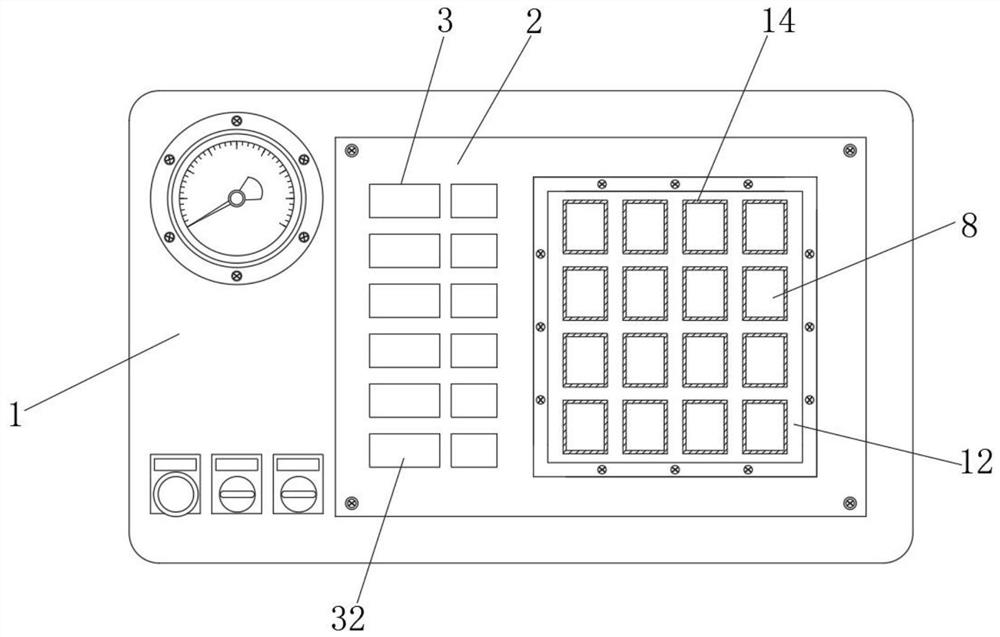

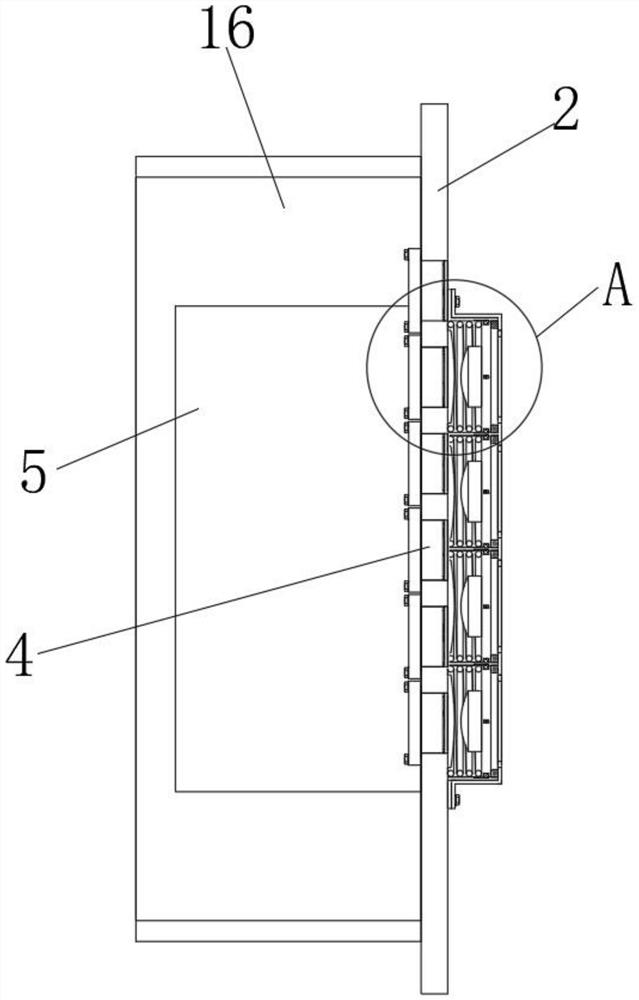

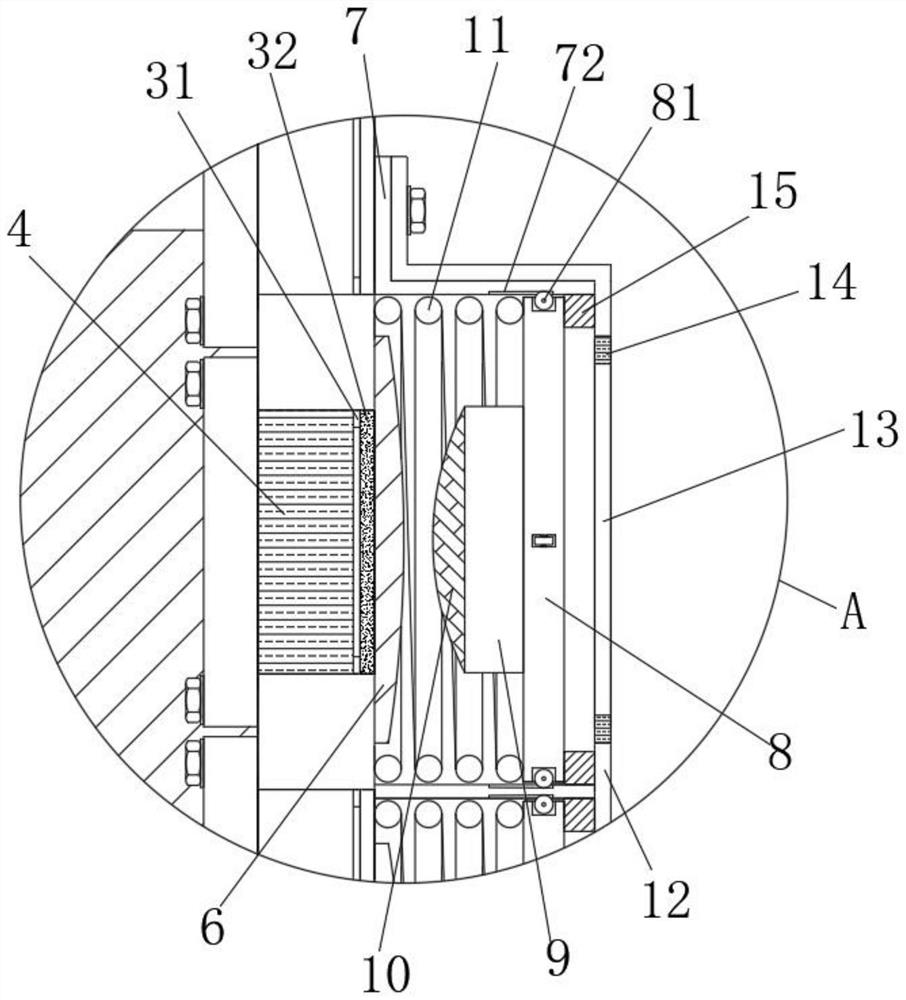

[0036] Example 1, see Figure 1-6, the control device for paper printing or laminating of the present invention includes a control cabinet 1 and a control device, the control device includes a controller mounting plate 2, an LED digital tube 4 and a digital input device 5, and the controller mounting plate 2 is fixed by screws Connected to the front of the control box 1, the front of the controller mounting plate 2 and near the left side are provided with a digital tube installation slot 3 for installing the LED digital tube 4 at equal distances along the vertical direction, and the LED digital tube 4 is installed from the digital tube installation slot 3 is inserted in the back and fixed with the back of the controller mounting plate 2 by screws, and the digital input device 5 is fixedly connected to the back of the controller mounting plate 2 and near the right side by screws, and the front of the controller mounting plate 2 is connected to the digital input device Button 6 ...

Embodiment 2

[0042] Embodiment 2: Different from Embodiment 1, the inside of the through hole 13 is glued and fixedly connected with a silicone gasket 14. The front view of the silicone gasket 14 is rectangular, which can prevent people's fingers from colliding with the inside of the through hole 13. played a protective role.

Embodiment 3

[0043] Embodiment 3: Different from Embodiment 1, a fixed frame 31 is integrally formed on the inside of the nixie tube installation groove 3 and near the front, and the front of the fixed frame 31 is glued and fixed with a transparent glass 32, and the front of the transparent glass 32 is connected to the digital The fronts of the tube mounting groove 3 are on the same horizontal plane, which can protect the LED digital tube 4 while not affecting people's observation of the numbers displayed by the LED digital tube 4 .

[0044] Working principle: When the staff needs to operate the button 6, they only need to press the pressure plate 8 with the corresponding text mark with their fingers. After the pressure plate 8 is under pressure, the return spring 11 will be compressed until the silicone protrusion 10 on the pressure plate 8 presses the button 6 times, at this time, the staff can confirm the success of the input by observing the changes in the numbers displayed on the LED d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com