Autoclaved lightweight aerated concrete product manufacturing and processing system

A technology of aerated concrete and processing system, which is applied in the directions of manufacturing tools, auxiliary molding equipment, supply devices, etc., can solve the problems of inconvenient production and processing, inability to adjust the length of the inner core, and adjustment of the pouring block.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

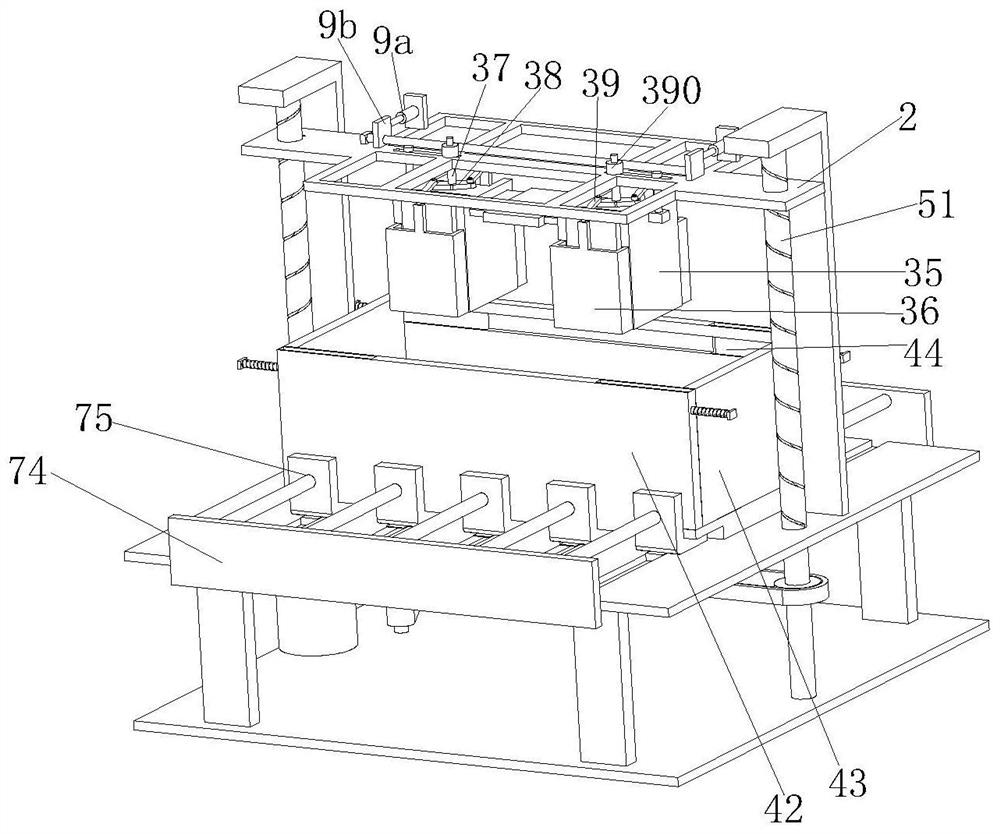

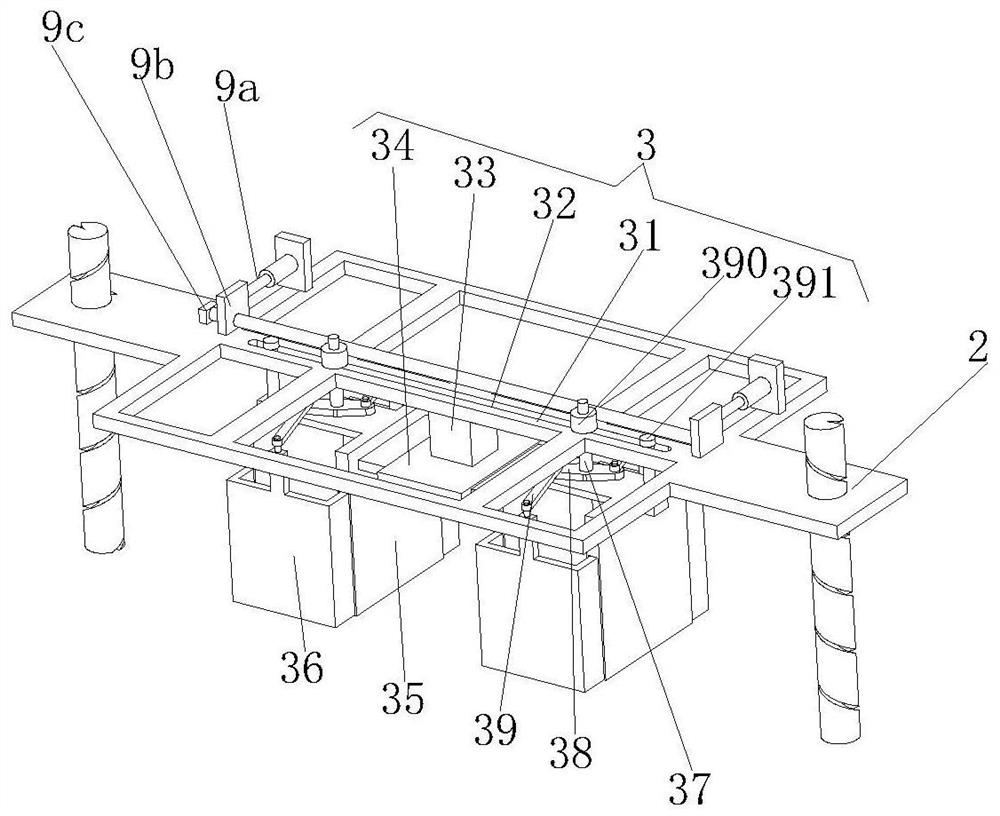

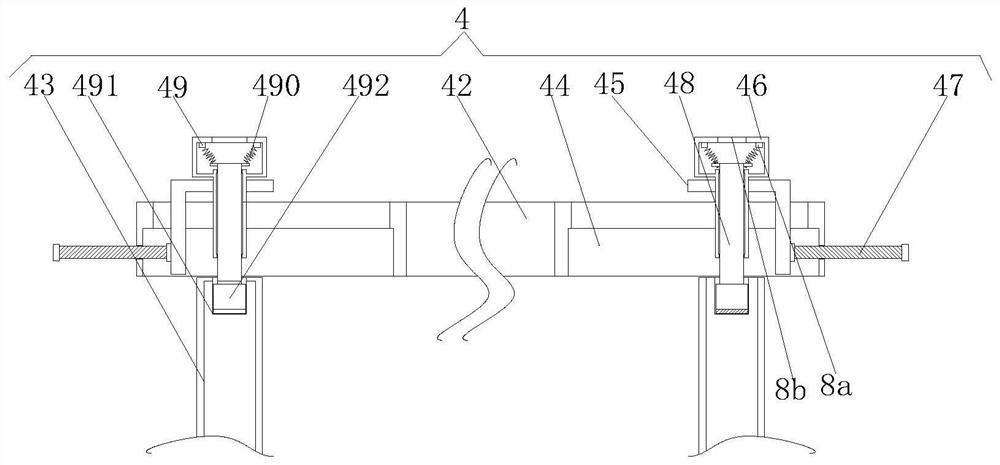

[0026] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 8 , to further elaborate the present invention.

[0027] An autoclaved lightweight aerated concrete product manufacturing and processing system, including a base 1, a support frame 2, an adjustment device 3, a moving device 4 and a lifting device 5, the upper surface of the base 1 is provided with a support frame 2, and the support frame 2 is provided with an adjustment device 3, and below the adjustment device 3 is provided a mobile device 4 connected to the base 1:

[0028]The adjustment device 3 includes a beam 31, an adjustment groove 32, a support column 33, a two-way telescopic plate 34, an inner core support frame 35, an inner core adjustment frame 36, an adjustment shaft 37, an adjustment wheel 38, a connecting rod 39, a worm wheel 390, a balance Rod 391 and leveling unit 6, crossbeam 31 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com