Automatic steamed bun production system and production process thereof

A technology for automatic production of steamed buns, applied in the field of steamed buns, which can solve the problems of tray deformation, affecting the steaming effect of steamed buns, and low utilization rate of heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

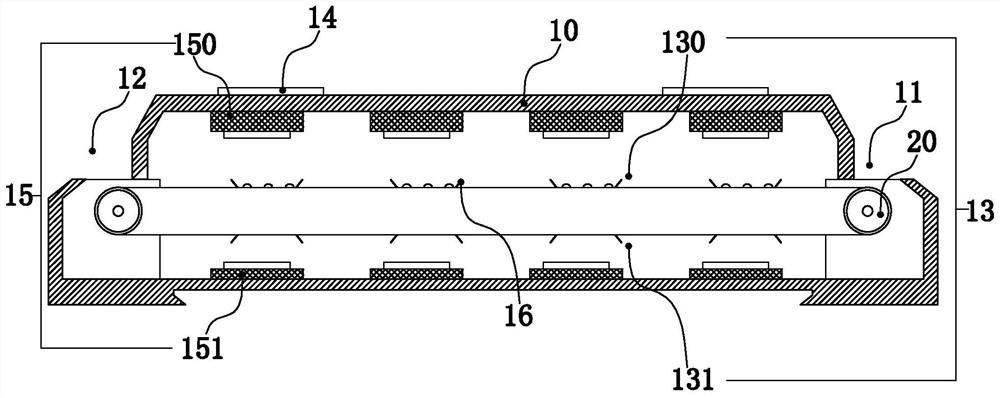

[0056] Such as figure 1 As shown, the present invention discloses an automatic production system for steamed buns, which includes an oven body 10, a baking channel 13 provided in the oven body 10 and having a discharge port 11 and a discharge port 12, and a baking channel 13 provided in the oven body 10. The humidity adjustment door 14 on the top, the heating module 15 provided in the baking channel 13 and the conveying device 20 provided in the baking channel 13 and used to transport the baked goods, in a specific embodiment of the present invention,

[0057] The conveying device 20 divides the baking tunnel 13 into a baking zone 130 and a preheating zone 131;

[0058] The heating module 15 includes a plurality of heating parts 150 arranged in the baking area 130 and arranged at intervals in the conveying direction of the conveying device 20 to heat the baked goods, and a plurality of heating parts 150 arranged in the preheating area 131 and The preheating section 151 arrang...

Embodiment 2

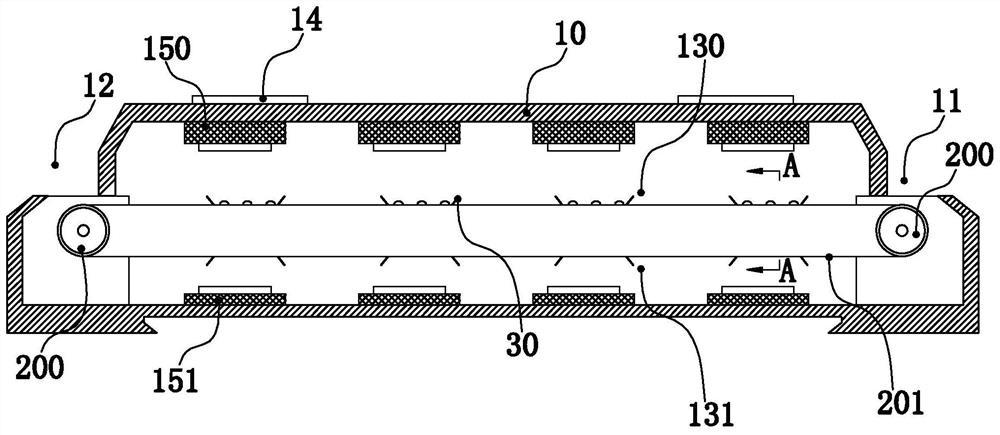

[0071] Embodiment 2, the difference with embodiment 1 is that

[0072] Such as Figure 2-Figure 4 As shown, in a specific embodiment of the present invention, the conveying device 20 includes a conveying wheel 200 installed at the discharge port 11 and the discharge port 12 and driven by a motor, and a conveyor belt 201 connected between the conveying wheels 200 And several tray devices 30 installed at intervals on the conveyor belt 201 for placing baked goods; the tray device 30 includes a tray body 300, a first air supply part 301 and a second air supply part 302;

[0073] When the tray device 30 is located in the baking area 130, the first air supply part 301 on the tray device 30 guides part of the airflow in the baking area 103 to flow around the outer wall of the tray body 300, and at the same time, all the air supply parts on the tray device 30 The second air supply part 302 guides part of the air flow from the baking zone 103 to the tray body 300 in the preheating zon...

Embodiment 3

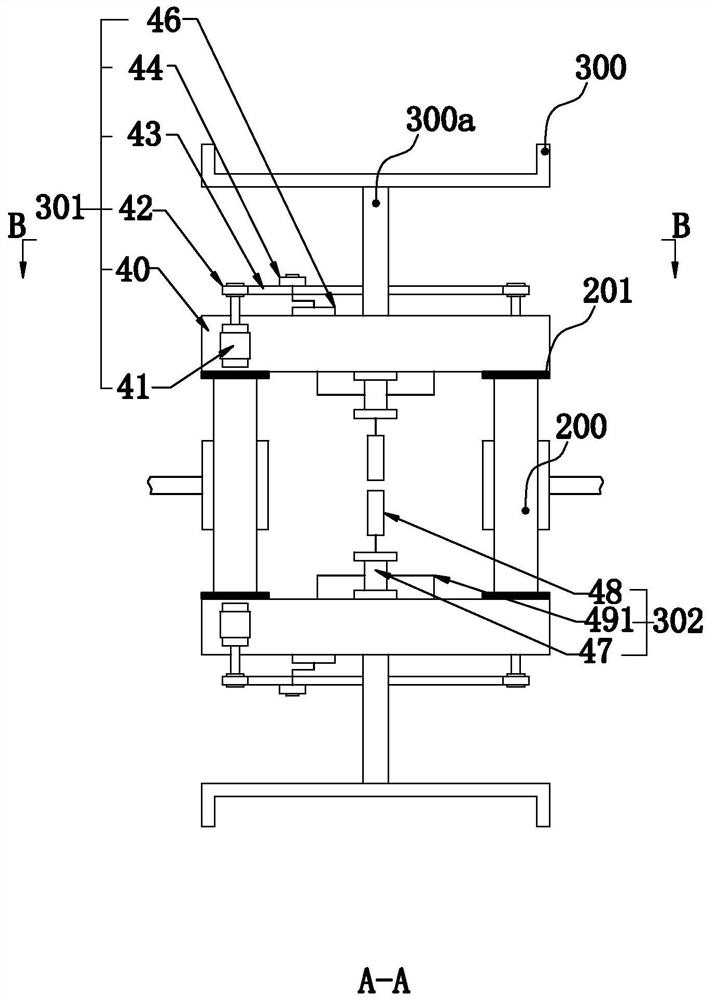

[0089] Embodiment 3, the difference with embodiment 2 is that

[0090] Such as Figure 5-Figure 6 As shown, in a specific embodiment of the present invention, the tray body 300 includes a support shaft 300a with one end connected to the center of the base plate 40, an outer barrel 300b installed at the free end of the support shaft 300a, and an outer barrel 300b disposed on the outer barrel 300b. The inner disc body 300c is arranged at a distance from the inner wall of the outer barrel 300b and can be driven by a motor to rotate. Through holes are distributed on the inner wall and the outer wall of the inner tray body 300c. The outer barrel 300b has an integrally formed first split body 3001b and The second split body 3002b, wherein, the cross-section of the second split body 3002b is arc-shaped with a radian larger than a semicircle, the cross-sectional shape of the first split body 3001b is rectangular and has at least two drainage walls 3003b, the first split body 3001b Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com