Novel continuous mining machine power cable take-up and pay-off device

A technology for power cables and retractable devices, which is applied to cable suspension devices, mining devices, cable installations, etc., can solve the problems of high labor intensity, electric leakage, increased risk of electric shock, and scratches on power cables, and reduces labor costs. The effect of labor intensity, reducing the risk of climbing work, eliminating the possibility of scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

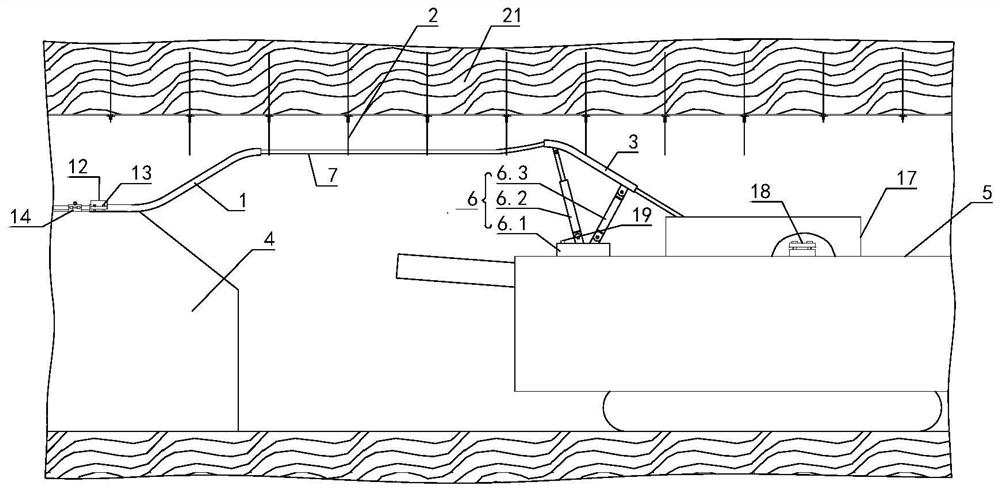

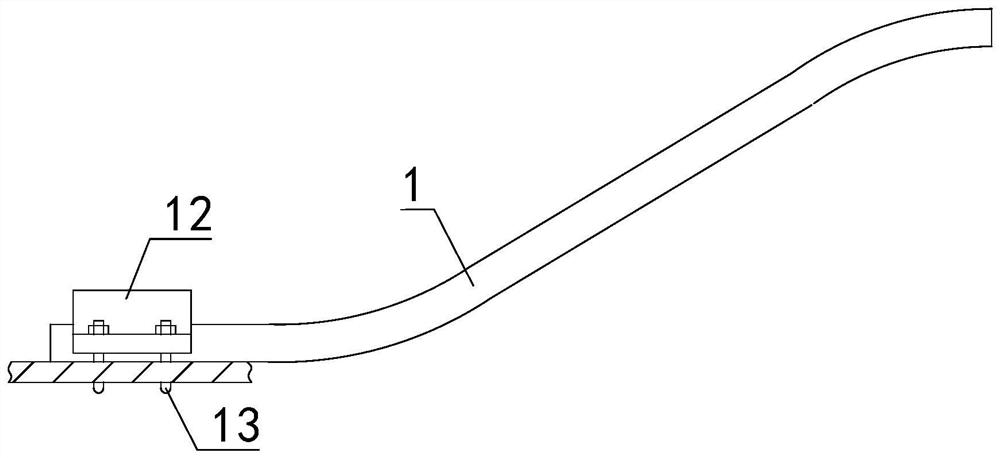

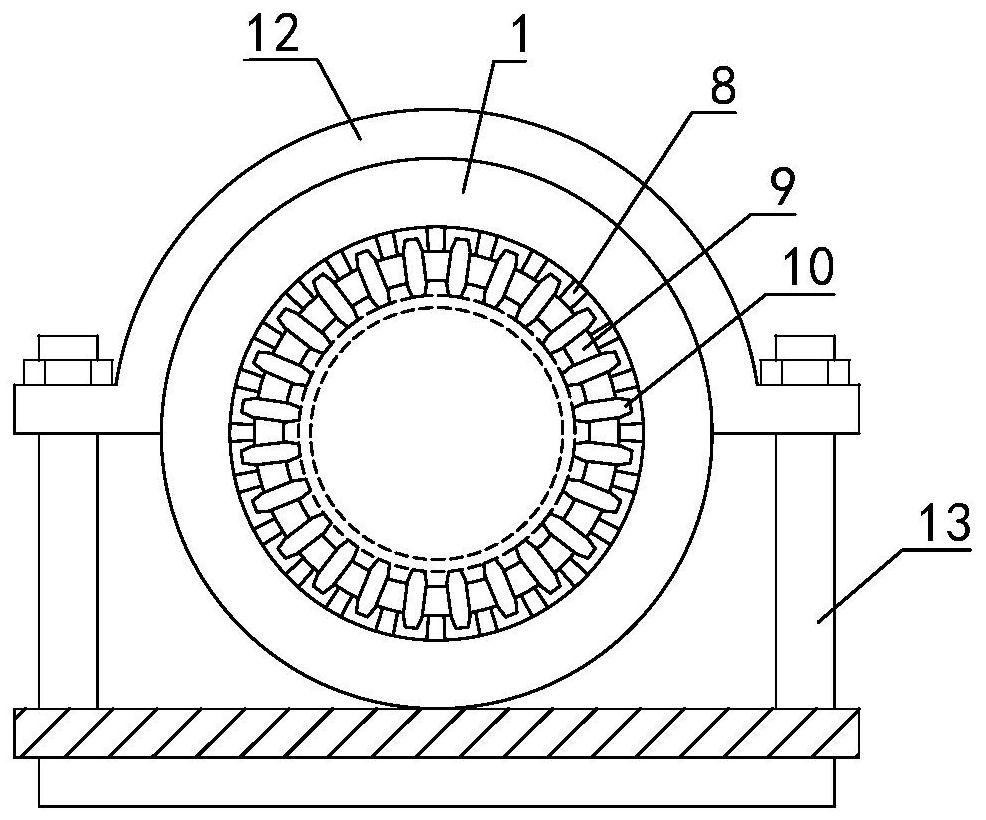

[0028] Embodiment 1: as Figure 1 to Figure 7 As shown, a new type of continuous mining machine power cable retracting device, which includes a crusher suspension slideway 1, a cable hook 2 and a continuous mining machine suspension slideway 3; Crusher suspension slideway 1 that is bent upward in the direction of mining machine 5, the wire inlet end of crusher suspension slideway 1 fits with the top cover of crusher 4 and the cover is provided with a compression hoop plate 12, which passes through The U-shaped bolt 13 is fixedly connected with the top cover of the crusher 4, which is convenient for disassembling and assembling the suspended slideway 1 of the crusher; The lower hoop plate of the first hoop 14 is fixedly connected with the top cover of the crusher 4 through bolts, and one side of the upper hoop plate of the first hoop 14 is rotatably connected with the corresponding side wall of the lower hoop plate through the hinge 15, and the first hoop 14 is fixed with a ca...

Embodiment 2

[0038] Embodiment 2: as Figures 1 to 4 , 7 to 11, a new type of continuous mining machine power cable retracting device, its overall structure is basically the same as that of Embodiment 1, the difference is that the cable pressing device 16 is a lock, and the upper part of the first clamp 14 The hoop plate is connected to the lower hoop plate of the first hoop 14 through a lock; when the continuous miner 5 is moving forward to the excavation, the power cable 7 is locked on the upper hoop plate and the lower hoop plate of the first hoop 14 through the lock During the excavation operation of the continuous miner 5, the lock is loosened so that the first hoop 14 on the crusher 4 should always be kept in a loose state. Under traction, the pulling power cable 7 is sent in from the first clamp 14 to increase the length of the power cable 7 from the crusher 4 to the excavation face.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com