Improved unwinding device of fabric cutting machine for producing garments

A technology of unwinding device and cloth cutting machine, which is applied in the direction of winding strips, transportation and packaging, thin material processing, etc., and can solve problems such as cloth falling to the ground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

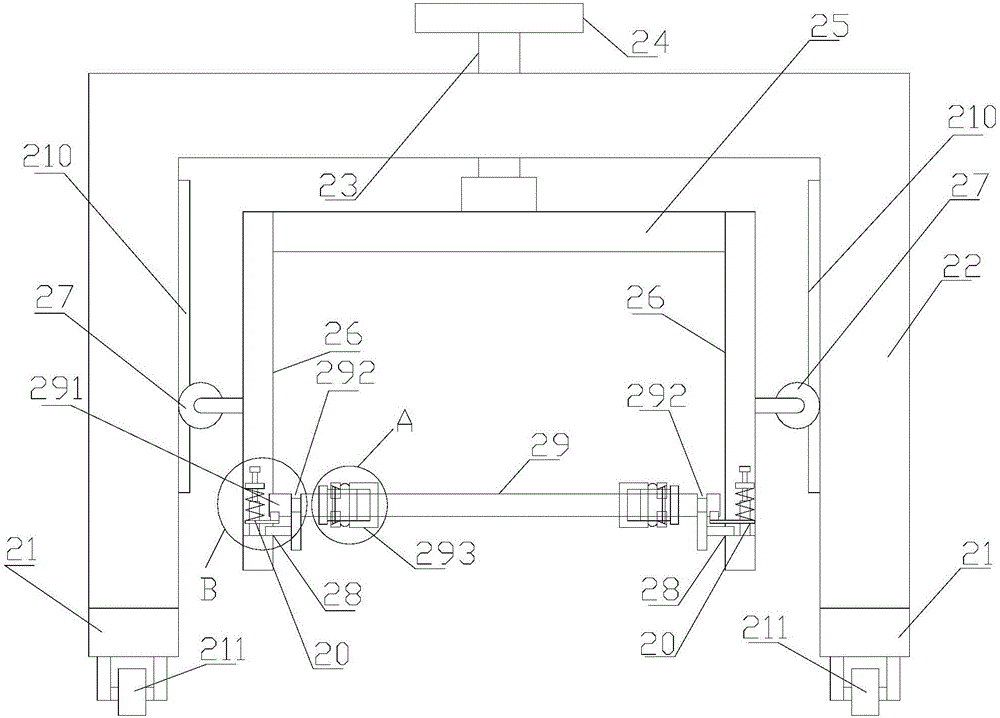

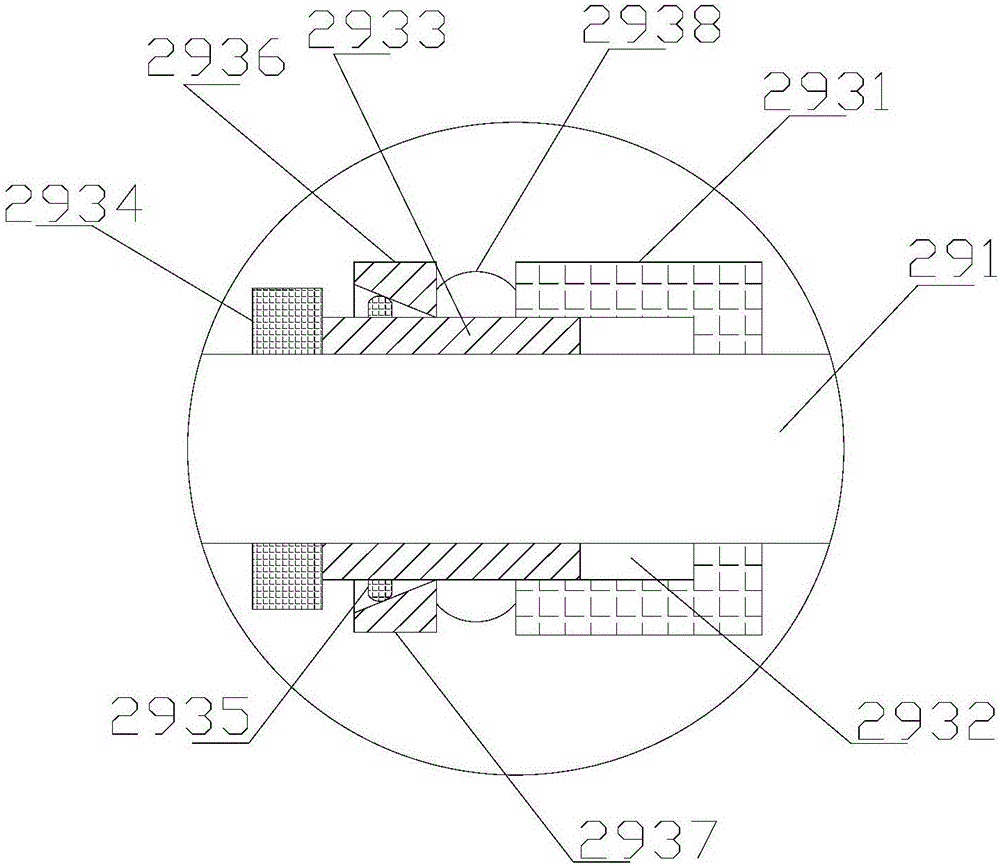

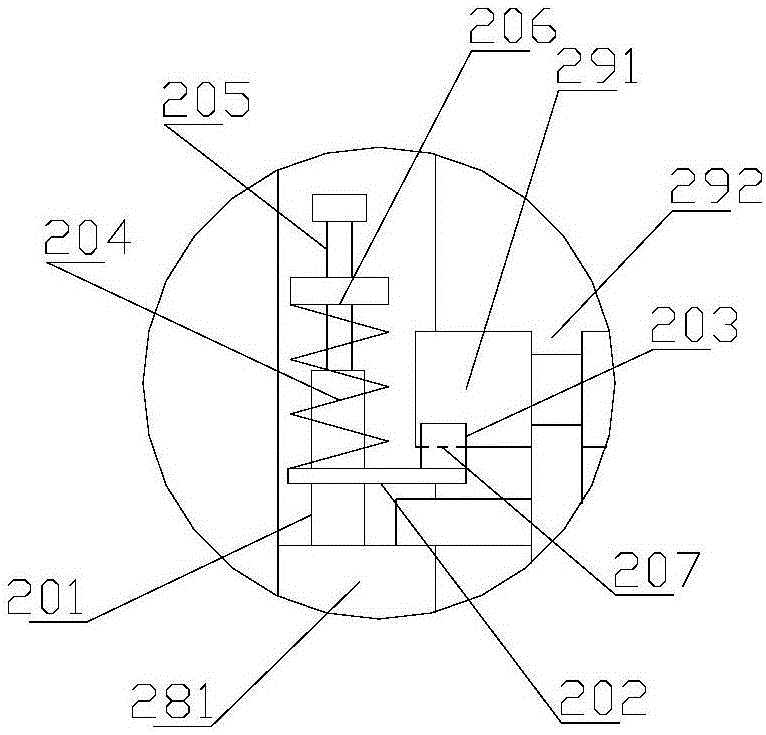

[0017] refer to figure 1 , figure 2 and image 3 , the present invention is an improved unwinding device for a cloth cutting machine for producing garments, comprising two bases 21, a gantry frame 22, a screw rod 23, an adjusting disc 24, a crossbeam 25, two connecting bodies 26, two shelving seats 28 and Unwind the reel 29, the lower ends of the two columns of the gantry 22 are respectively provided with a base 21, the beam body of the gantry 22 is threaded with a threaded screw 23, and the upper end of the screw 23 is provided with an adjusting disc 24 The lower end of the screw rod 23 is provided with a rotatably connected beam 25, and both ends of the beam 25 are provided with a connecting body 26, and the connecting body 26 is slidably connected with the column of the corresponding gantry frame 22. The lower end of the connecting body 26 is provided with a shelving seat 28, and the unwinding shaft 29 is placed on the shelving seat 28, and the unwinding shaft 29 include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com