Low-cycle fatigue composite test device

A composite test, low cycle fatigue technology, used in measuring devices, mechanical parts testing, machine/structural parts testing, etc. It can solve the problems of insufficient test power and efficiency, high cost, and inconvenient installation, and achieve easy batch production. The effect of experiment, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

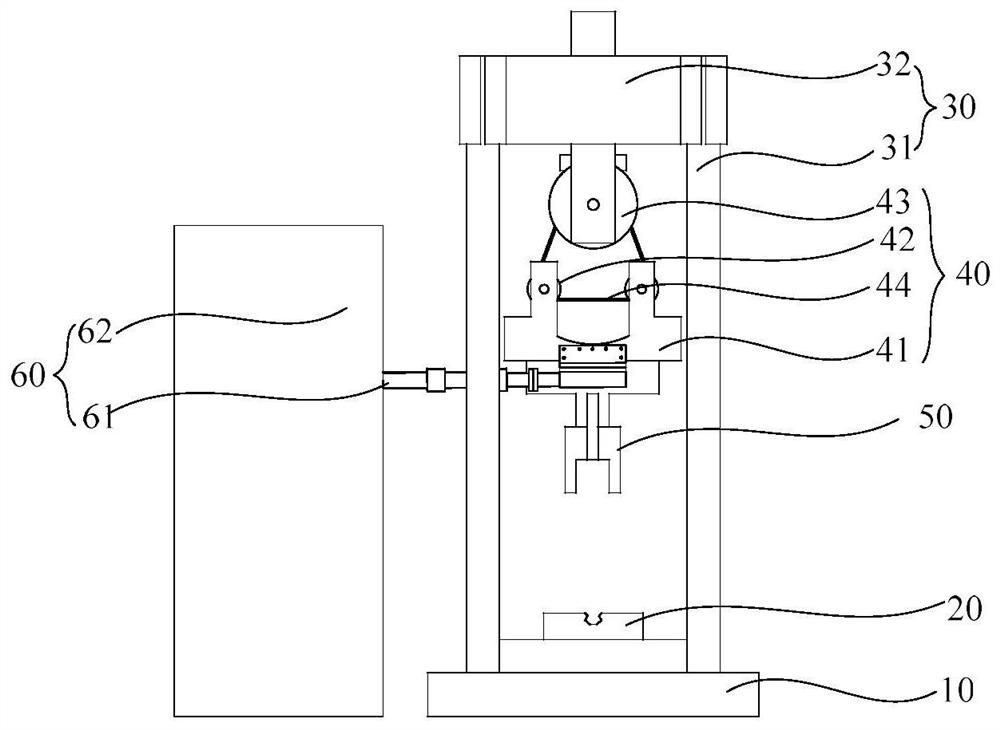

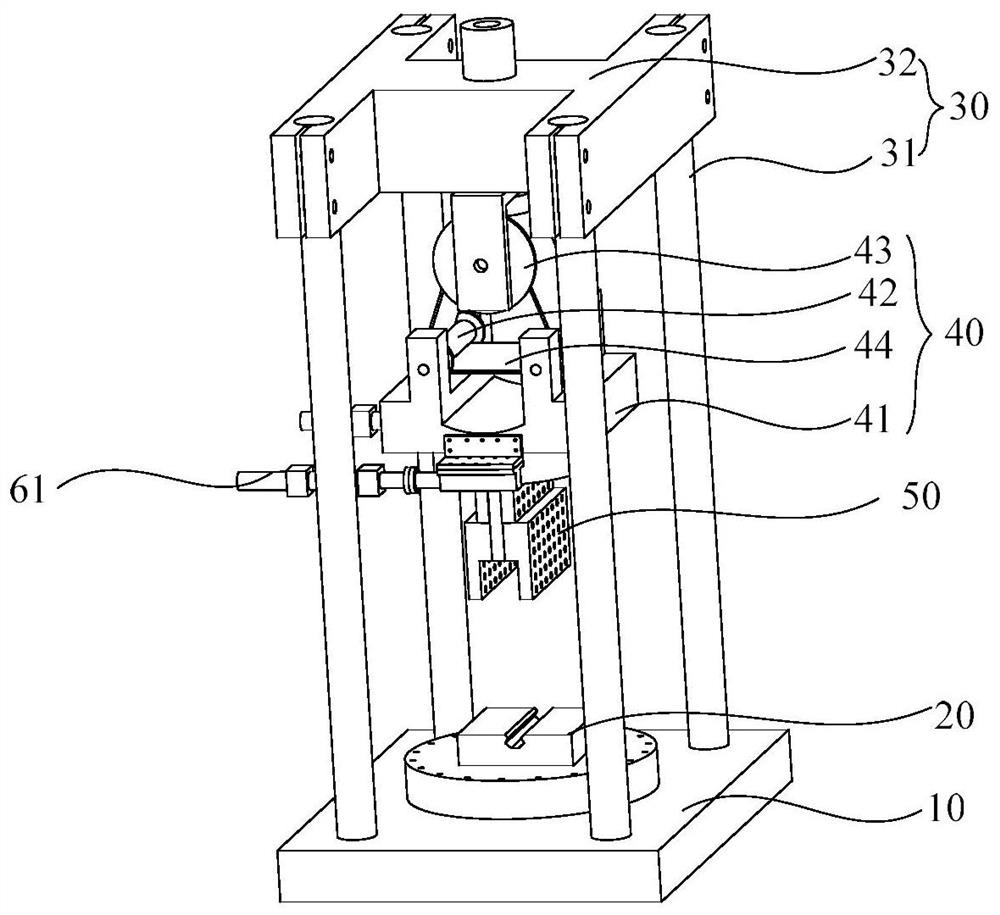

[0052] Such as Figure 4 As shown, in one embodiment of the present application, the horizontal moving device 40 includes: a sliding seat 41 , a plurality of rollers 42 , a fixed pulley 43 and a connecting belt 44 .

[0053] The sliding seat 41 is connected with a load applying device 60 .

[0054] A plurality of roller shafts 42 are arranged on the sliding seat 41 and can rotate relative to the sliding seat 41 , and axes of the plurality of roller shafts 42 are located in the same parallel plane. In a specific embodiment of the present application, two roller shafts 42 are arranged on the sliding seat 41 , and there is an interval between the two roller shafts 42 , and the fixed pulley 43 and the two roller shafts 42 are arranged in a triangle.

[0055] The fixed pulley 43 is connected with the rotating device and can rotate relative to the rotating device, and the axis of the fixed pulley 43 is parallel to the parallel plane.

[0056] The connecting belt 44 is connected wi...

Embodiment 2

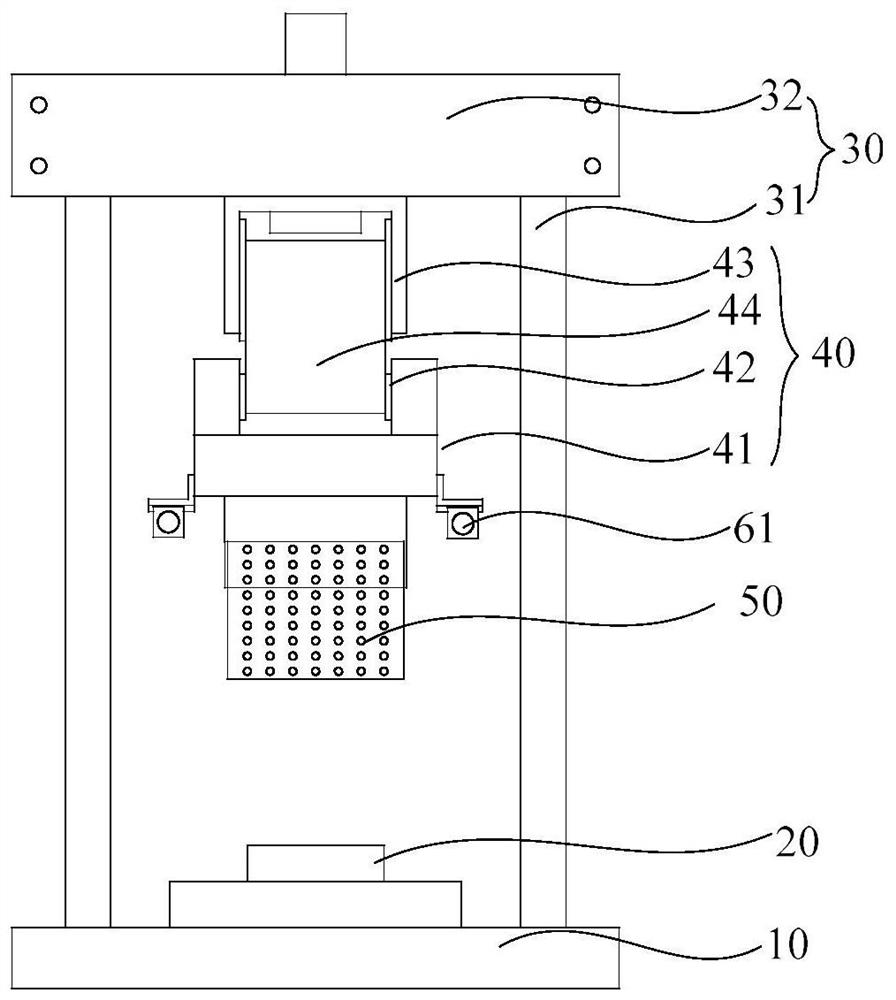

[0059] Such as Figure 5 and Figure 6 As shown, in one embodiment of the present application, the horizontal moving device 40 includes: a fixing part 45 and a sliding part 46 .

[0060] The fixing part 45 is connected with the rotating device, and a slide groove is arranged on the fixing part 45 .

[0061] The sliding part 46 is connected with the load applying device 60 , the sliding part 46 is provided with a slide rail, the sliding part 46 is connected with the fixed part 45 , and the slide rail is located in the slide groove, and the slide rail can move in the slide groove.

[0062] The load applying device 60 applies an external force to the sliding part 46, and through the cooperation of the chute and the slide rail, the sliding part 46 slides on the fixed part 45, so that the sliding seat 41 moves relative to the fixed pulley 43 and exerts an external force on the impeller in the horizontal direction .

[0063] In one embodiment of the present application, a plurali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com