Double-wheel milling mixer knife rest hose switching protection frame device

A mixer and double-wheel milling technology, which is applied in the direction of earth mover/excavator, construction, etc., can solve the problems of serious wear, no transfer protection frame, lack of hose angle change, etc., to achieve simple installation and disassembly, and reduce wear , is conducive to the effect of guiding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

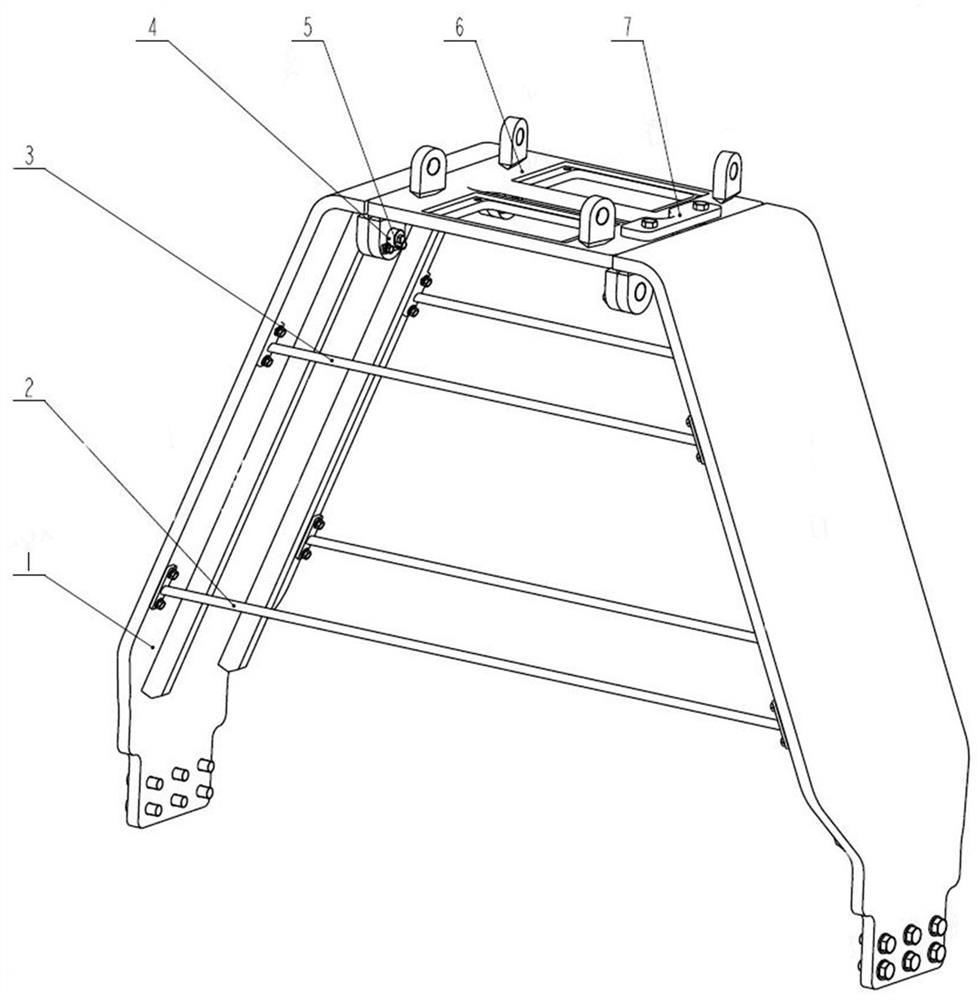

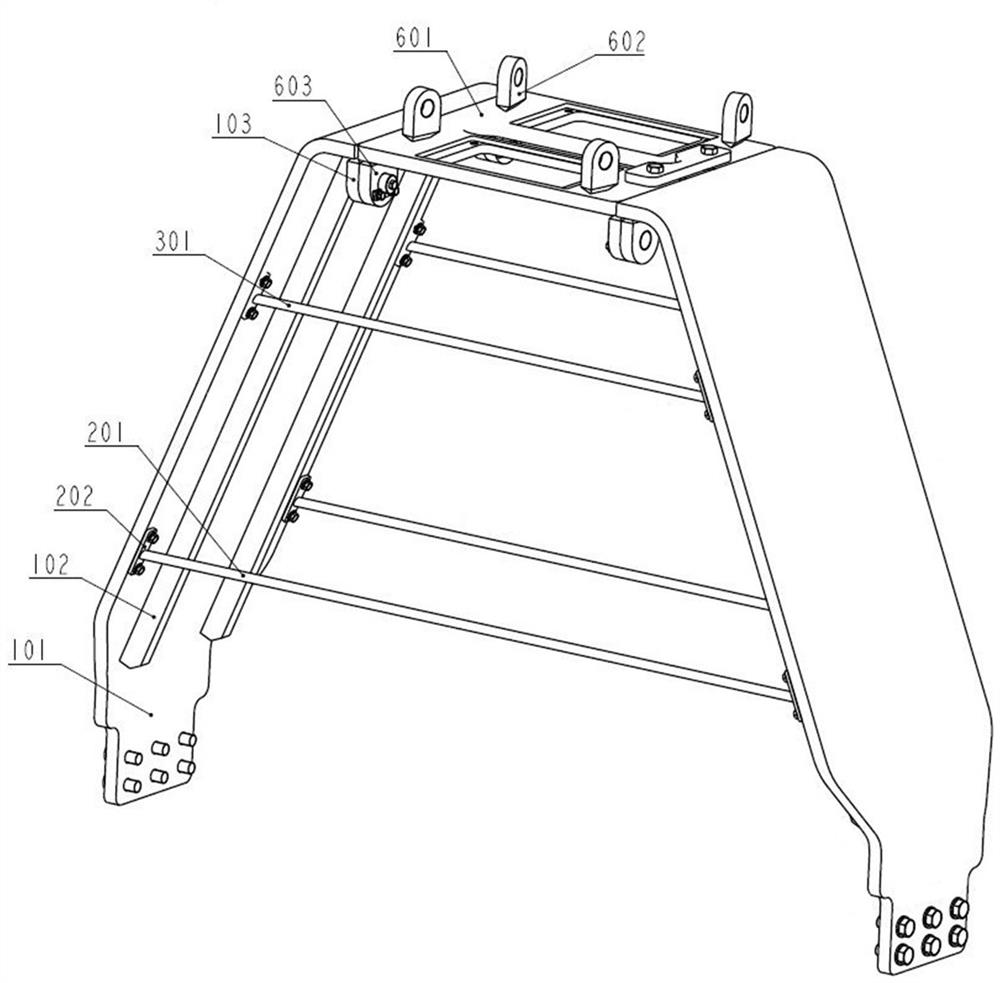

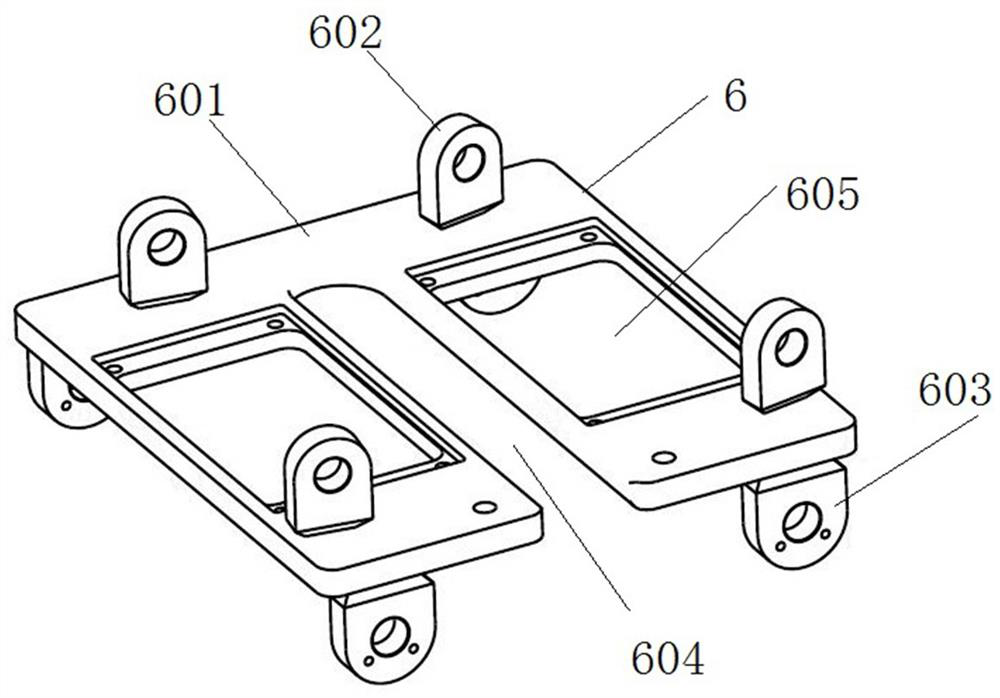

[0023] Such as Figure 1 to Figure 6 The shown one-wheel milling mixer tool holder hose transfer protection frame device includes two side support plates 1 symmetrically arranged on the tool holder 12, and the lower end of the side support plate 1 is fixed on the tool holder 12, The upper ends of the two side support plates 1 are connected together through a transfer transition frame 6, and the transfer transition frame 6 includes a 0° transfer transition frame and a 90° transfer transition frame, and the transfer transition frame 6 is provided with There is a middle groove 604 for passing the wire rope 8, and the transfer transition frame 6 is located on both sides of the middle groove 604, and there are side grooves 605 for installing the hydraulic transition valve block, and there is also a gap between the two side support plates 1 The upper protection tube 3 and the lower protection tube 2 are arranged symmetrically on both sides of the side support plate 1 . The double-w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com