Hardware paint spraying workbench with clamping function

A workbench and hardware technology, applied in the direction of spraying devices, etc., can solve the problems of heavy weight, complex surface shape, overhead fixing, etc., and achieve the effect of reducing workload, shortening operation time, and wide processing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: Please refer to Figure 1-Figure 5 , the specific embodiments of the present invention are as follows:

[0030] The invention provides a workbench for metal painting with clamping function, the structure of which includes a bracket 1, a placement platform 2, a controller 3, an air suction device 4, and a partition 5, and a placement platform 2 is welded on the top of the bracket 1 , the controller 3 is installed on the right end of the front of the support 1, the air suction device 4 is embedded and connected to the rear end above the placement table 2, and the partition 5 is provided with two pieces, and the two partitions 5 pass through the The glue solution is bonded to the left and right sides above the placement platform 2 .

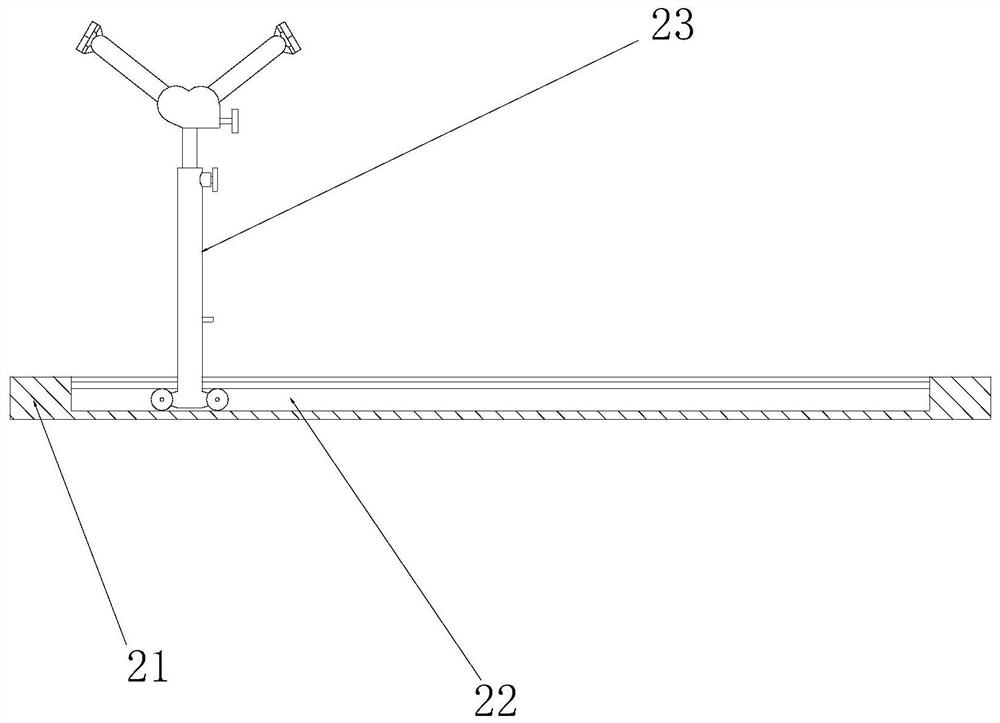

[0031] Described placement platform 2 is made up of plate body 21, slide rail 22, fixture 23, and described plate body 21 is provided with slide rail 22 inside, and slide rail 22 and plate body 21 are integrated structure, and des...

Embodiment 2

[0037] Example 2: Please refer to Figure 6-Figure 9 , the specific embodiments of the present invention are as follows:

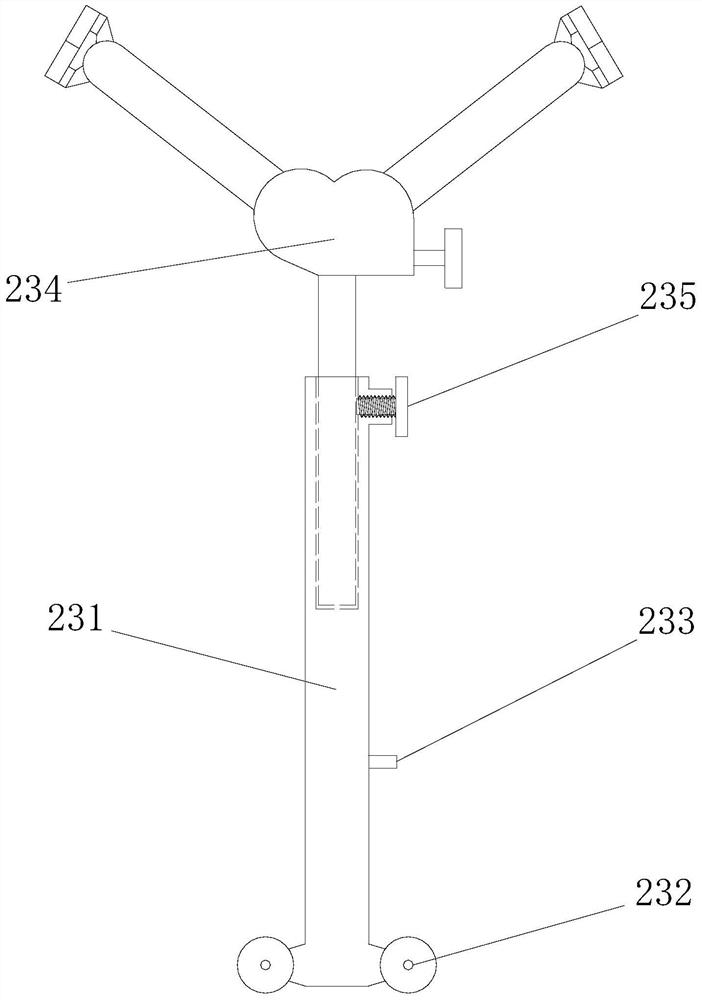

[0038] The present invention provides a workbench for metal painting with clamping function, the fixer 234 is composed of a support rod 341, an angle adjuster 342, and an index rod 343, and the upper part of the support rod 341 is welded and connected to the angle adjuster 342 Below, there are two indexing rods 343 , and the lower ends of the two indexing rods 343 are symmetrically installed inside the angle adjuster 342 .

[0039] The angle adjuster 342 is composed of a housing 421, a worm 422, a knob 423, a first gear 424, a second gear 425, and a movable groove 426. The lower end of the inner wall of the housing 421 is movably engaged with the worm 422, and the left end of the knob 423 is welded Connected to the right end of the worm 422, the outer ring of the first gear 424 meshes above the worm 422, the second gear 425 meshes with the first gear 424,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com