Low-loss ratooning rice harvester and method thereof

A technique for ratooning rice and harvesting machines, which is applied to the harvesters, the chassis of agricultural machinery, agricultural machinery and machinery, etc. It can solve the problems affecting the output and loss of rice in the second season, and achieve the reduction of subsidence depth, reduction of rolling rate, and The effect of broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

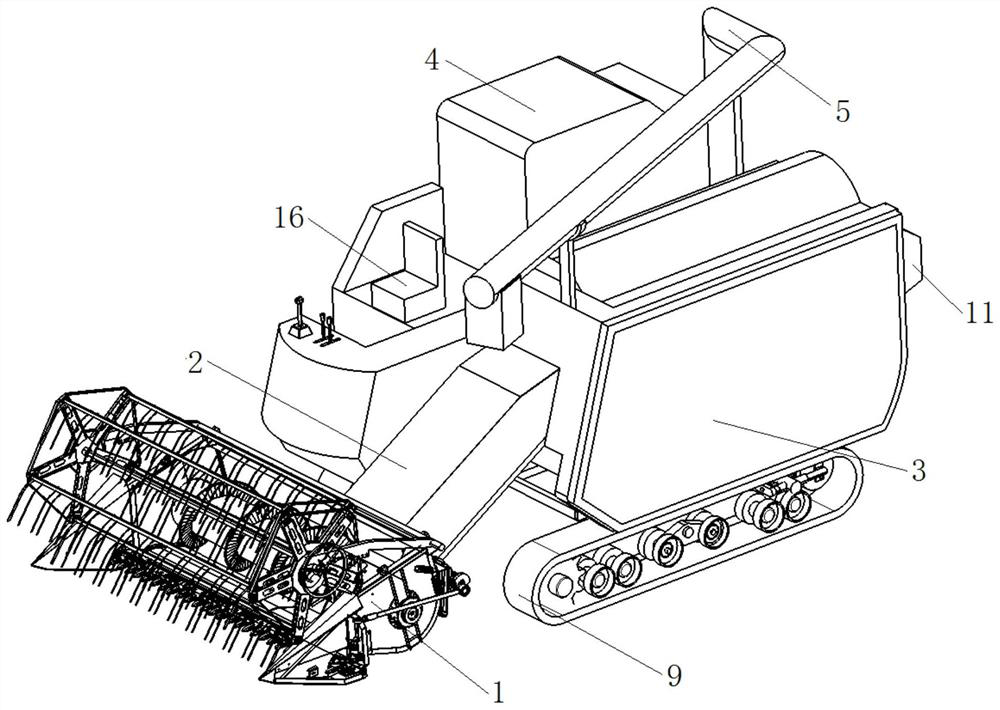

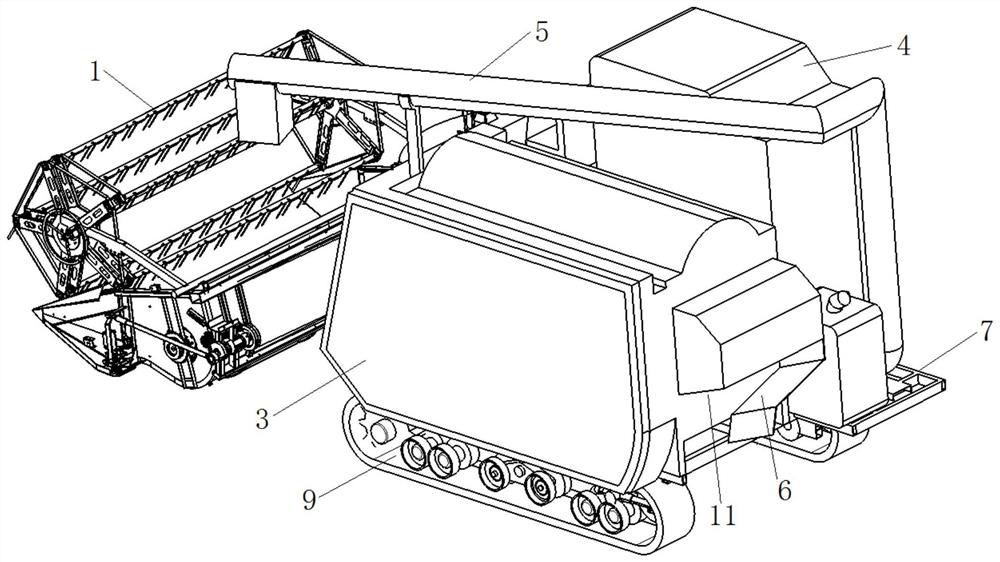

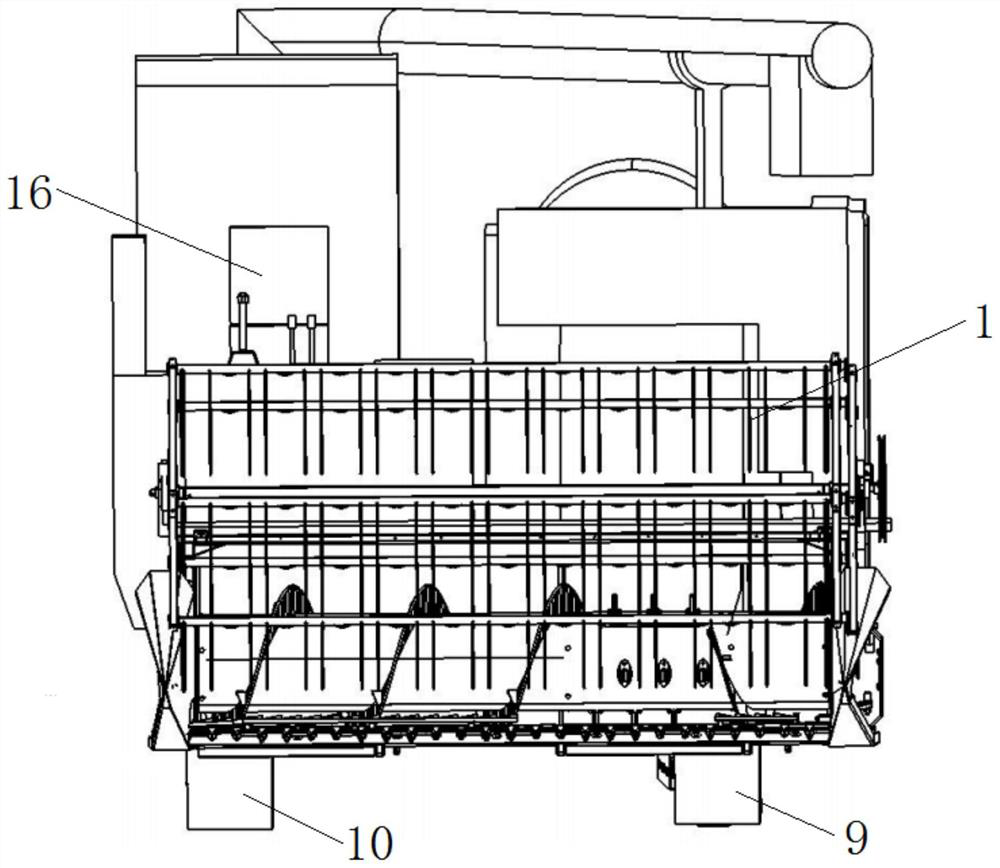

[0026] Such as Figure 1-Figure 4 The low-loss harvester for ratooned rice shown includes a header 1, a conveying system 2, a threshing and sorting system 3, a grain tank 4, and a grain unloading pipeline 5, as well as a driving mechanism, a walking mechanism with narrow shoe widths and a waste guide plate 6. The walking mechanism with narrow track width spacing includes a chassis 7, a high clearance chassis support 8, a left narrow track 9 and a right narrow track 10; the left narrow track 9 and right narrow track 10 pass through the high clearance chassis support 8 is connected to the chassis 7, the grain tank 4 and the threshing and sorting system 3 are installed on the chassis 7, the front of the grain tank 4 is provided with a cab 16, and the header 1 is connected to the threshing and sorting system through the conveying system 2 3, the grain unloading pipeline 5 is connected to the grain tank 4, the outer side of the narrow crawler belt 10 on the right side is flush with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com