Spherical projectile body casting device

A projectile and projectile technology, which is applied to weapon types, weapons without explosives, offensive equipment, etc., can solve problems such as large difficulties, large size and weight of spheres, and inability to place spheres, and achieve the effect of increasing the range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

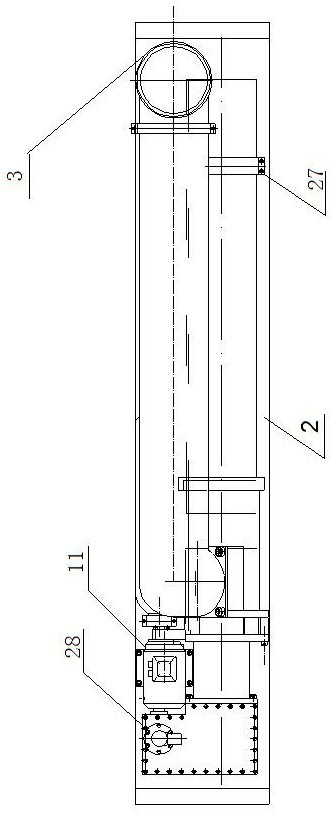

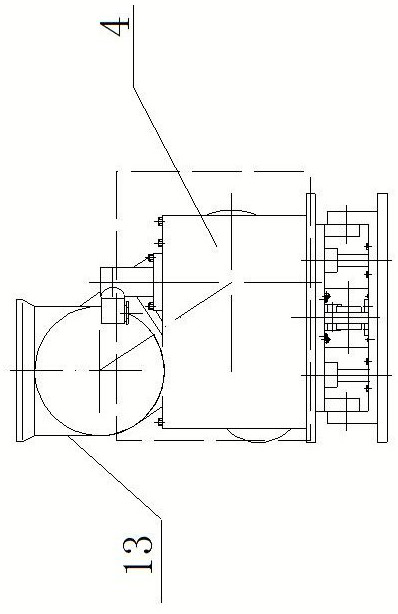

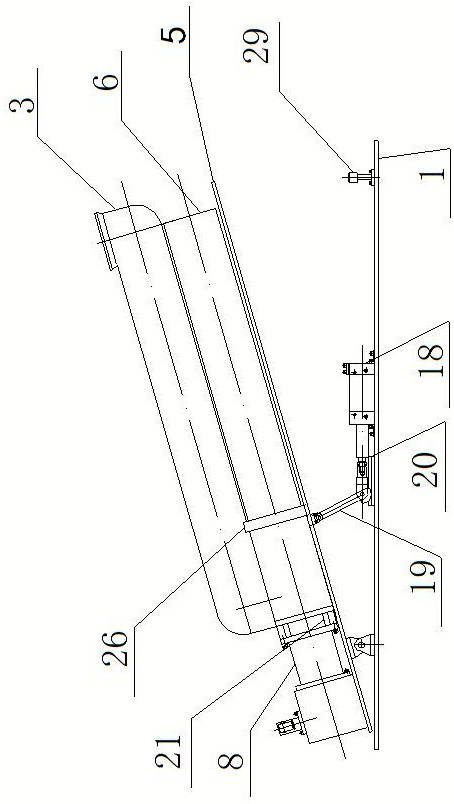

[0034] Embodiment 1: Reference figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 , a kind of ball projectile ejector of the present invention, comprises fixed plate 1, and a projectile that is arranged on fixed plate 1, and ejector includes the launching mechanism 2 that is arranged on fixed plate 1 top, projectile conveying cylinder 3, and The gas storage mechanism 4, the launch mechanism 2 includes the base plate 5 whose rear end is hinged with the fixed plate 1, the launch tube 6 fixedly installed on the base plate 5 through the launch pressure plate seat and the launch tube pressure plate 27, and the launch tube 6 through the fastening ring 26 and the launch tube 6. The connected launching seat 7, the connecting pipe 8 connected to the rear end of the launching seat 7 through the spacer sleeve 21, the rotatable bullet sleeve 9 arranged in the launching seat 7, the front and rear sliding top in the connecting pipe 8 Bullet ...

Embodiment 2

[0041] Embodiment two: reference image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 and Figure 11 , the structure of this embodiment is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that two ejectors are arranged on the fixed plate, and the two ejectors are arranged on the fixed plate in an opposite form. , one of the projectiles has its launch tube facing forward, and the other projectile's launch tube is facing backward.

[0042] By arranging two ejectors on the fixed plate, a spherical projectile ejector can launch balls in two directions forward and backward at the same time, which can meet the launching requirements of different places.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com