Smoke exhaust fireproof valve

A fire damper and valve plate technology, applied in sliding valves, valve details, safety valves, etc., can solve the problems of thermal expansion of the valve plate group, the fire valve can not be completely closed, and can not be opened and closed, so as to protect the valve plate assembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

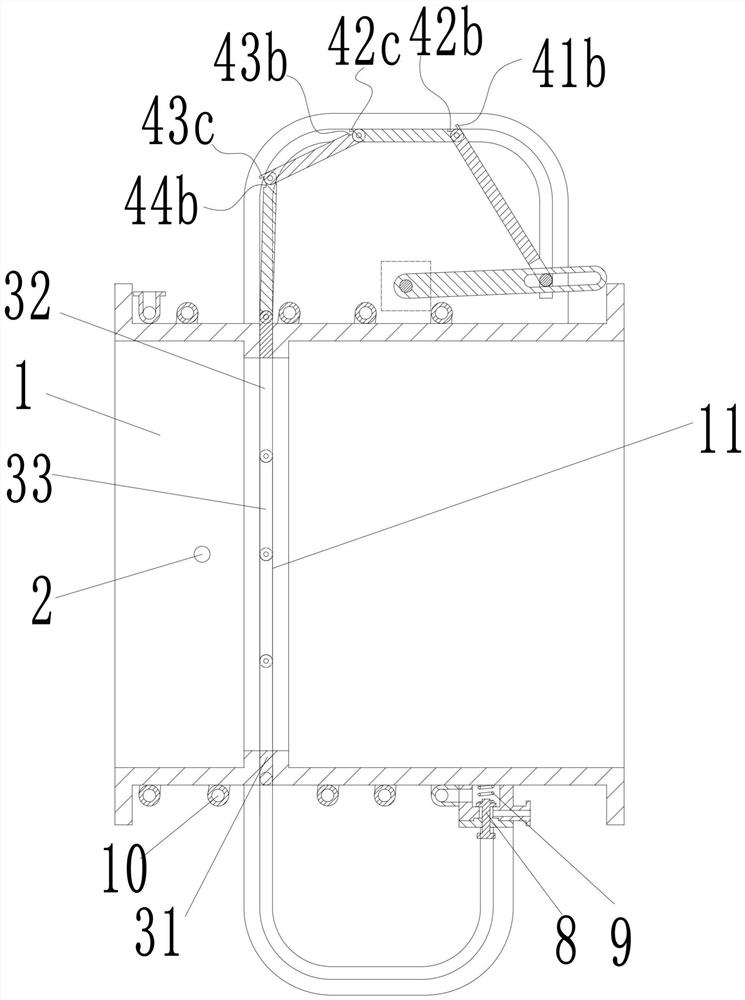

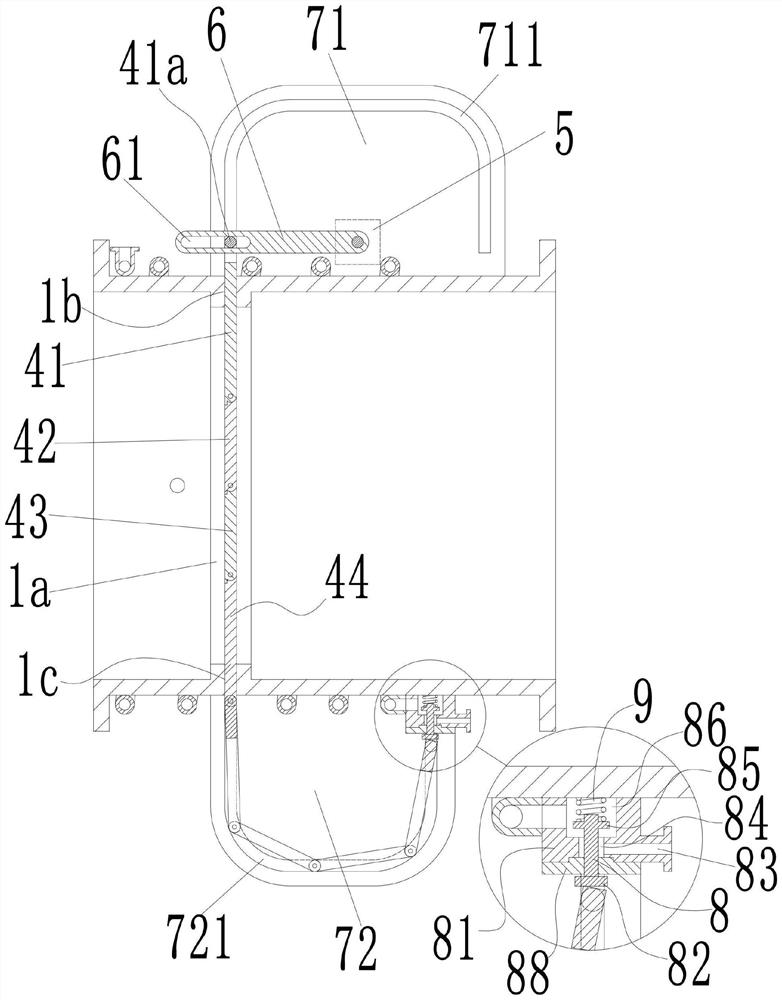

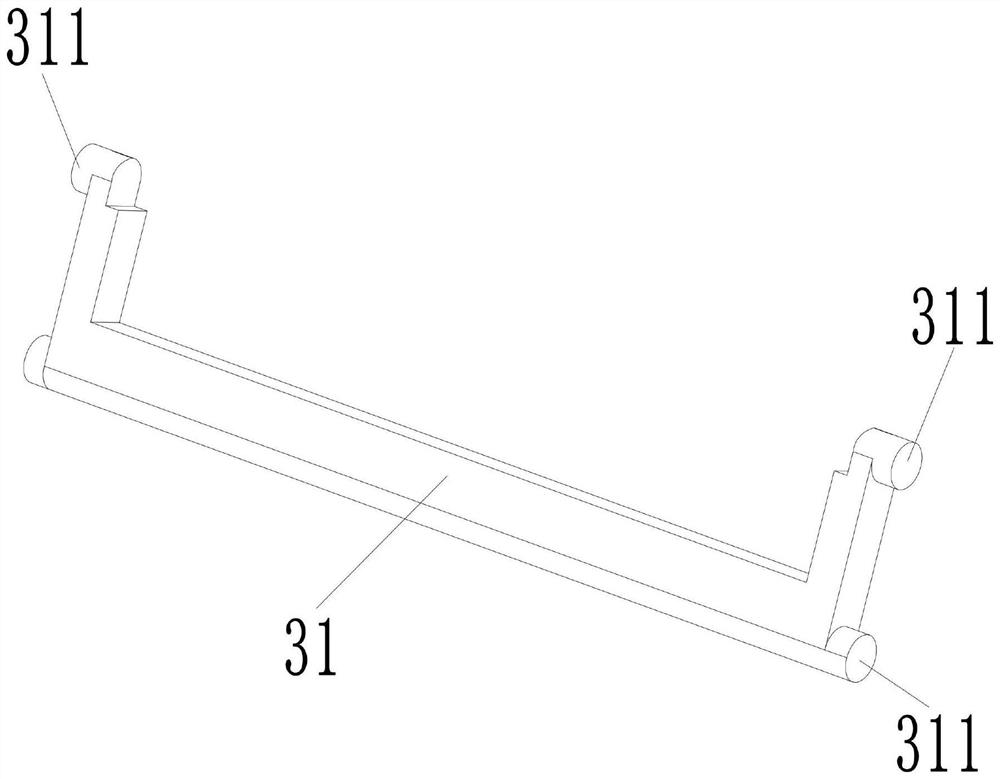

[0027] see Figure 1-7 As shown, a smoke exhaust fire damper includes a valve frame assembly and a valve plate assembly, and a valve pipe 1 with a square cross section. The left end of the valve pipe 1 is the inlet end, and the right end is the outlet end. The valve pipe 1 The inner side wall is provided with an annular shoulder 1a, the front and rear sides of the annular shoulder 1a are provided with a first track groove 11 along the vertical direction, and the upper end of the valve pipe 1 is provided with an upper groove communicating with the upper end of the first track groove 11 Port 1b, the lower end is provided with the lower notch 1c that communicates with the lower end of the first track groove 11; A lower track assembly is provided; the valve frame assembly is connected with the valve plate assembly, and the valve frame assembly slides in the first track groove 11 or the lower track assembly; the valve plate assembly is slidably connected in the first track groove 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com