Combined reinforced joint for connection of steel beam and wide concrete filled steel tubular column

A technology for concrete filled steel tubular columns and concrete columns, which can be applied to buildings and building structures, etc., can solve problems such as easy protruding, affect the appearance of buildings, and cannot be poured with concrete, so as to improve the stress state, improve the seismic ductility, and ensure the rigidity and strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

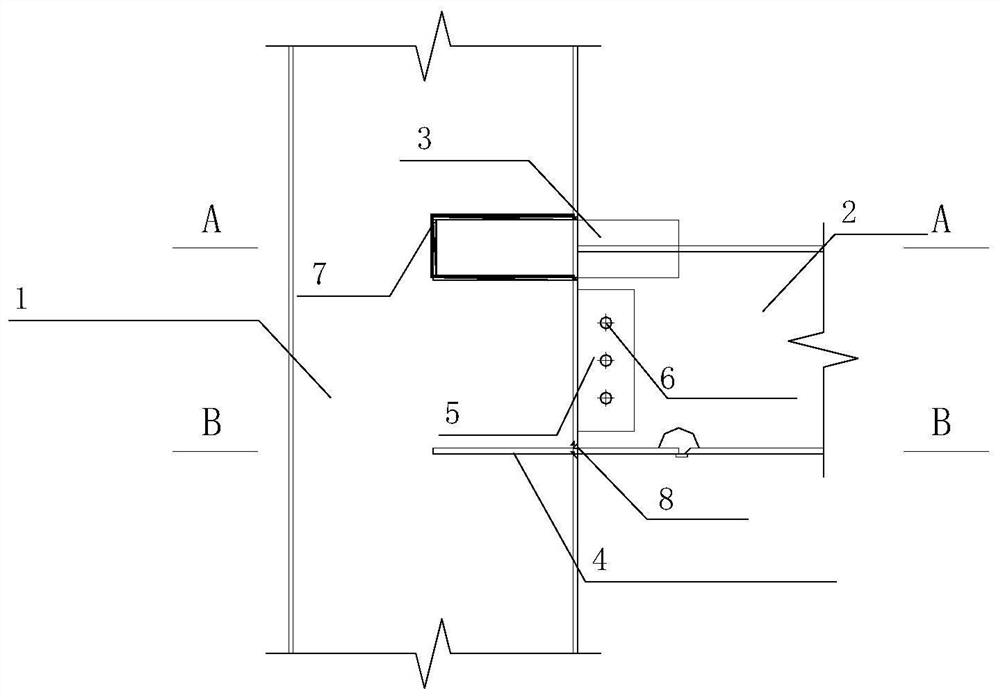

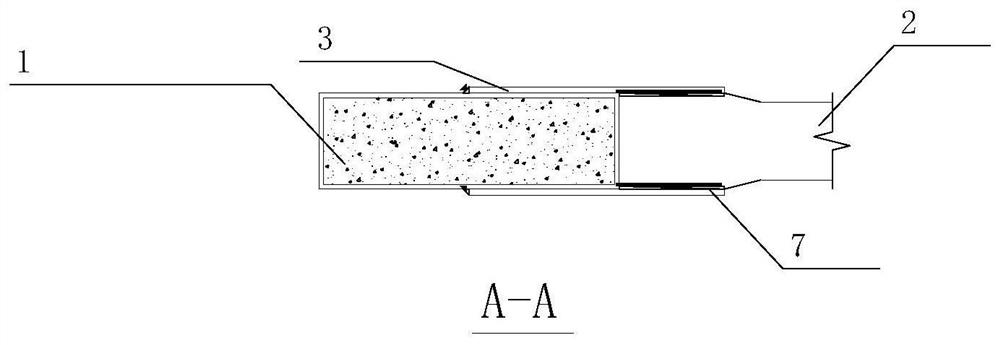

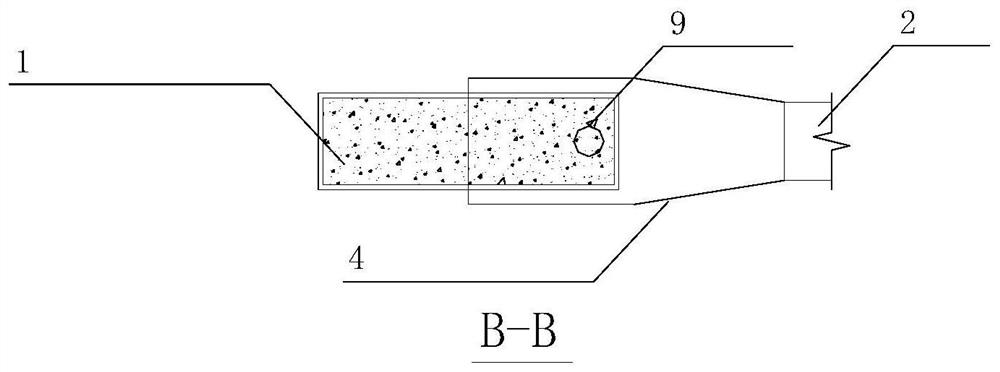

[0052] Such as Figure 1-3 Shown, the present invention comprises wide steel pipe concrete column 1, steel girder, outer sticking board, part through transverse diaphragm, connecting plate and vertical inserting plate; figure 1 As shown, the short side of the wide CFST column 1 is connected to the steel beam, and the upper flange, lower flange, and web of the steel beam are respectively connected to the wide The short sides of the steel tube concrete column 1 are connected to the column walls. The wide steel pipe concrete column 1 is formed by pouring concrete inside a rectangular steel pipe, and the ratio of the long side to the short side of the rectangular steel pipe is 1-4. The steel beam is an H-shaped steel beam, and the flange of the steel beam is welded to the column wall of the wide steel pipe concrete column 1.

[0053] One short side of the wide steel pipe concrete column 1 is connected to the first steel beam 2 after passing through two first external panels 3 , ...

Embodiment 2

[0057] Such as Figure 4-6 As shown, when the wide concrete-filled steel tube column 1 is located in the middle of the building plane, the two sides of the long side of the wide steel tube concrete column 1 are respectively connected to two steel beams through vertical inserts, and the vertical inserts are respectively connected to the external laminate and part of the The diaphragms are connected.

[0058] When the wide concrete-filled steel tube column 1 is located in the middle of the building plane, the other short side of the wide steel tube concrete column 1 passes through two second external panels 13, a second partly penetrating transverse partition 15, a second connecting plate and the fourth Steel beams 22 are connected;

[0059] One side of the upper flange of the fourth steel beam 22 and the side where the long side of the wide steel pipe concrete column 1 is located are connected by a second external plate 13, the other side of the upper flange of the fourth stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com