Automatic feeding equipment for mylar

A technology of automatic feeding and mylar sheeting, applied in the direction of conveyor objects, transportation and packaging, conveyors, etc., can solve the problems of low efficiency and high labor intensity, and achieve the effect of reducing labor intensity and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

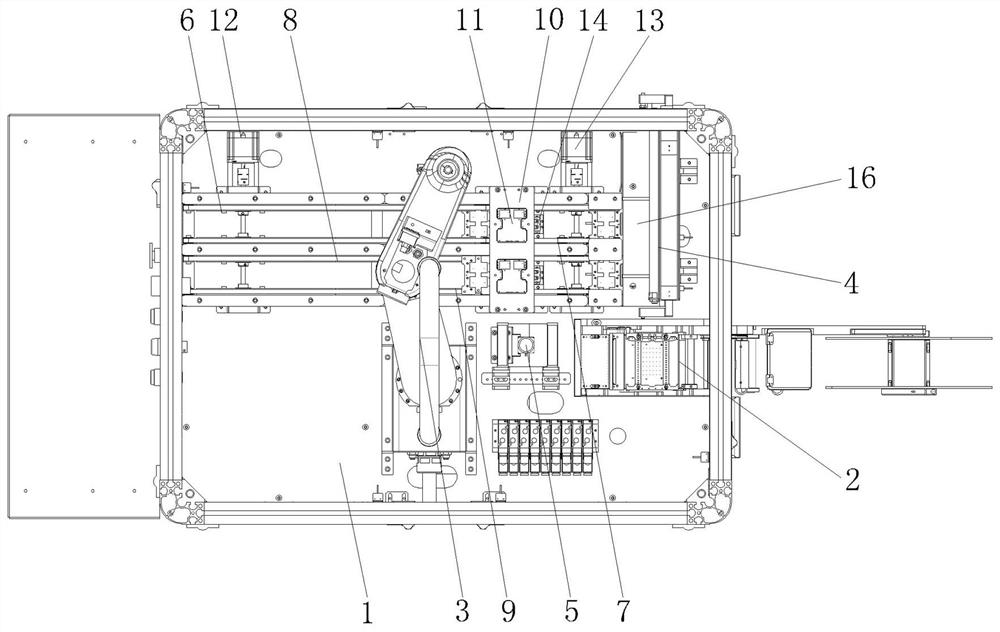

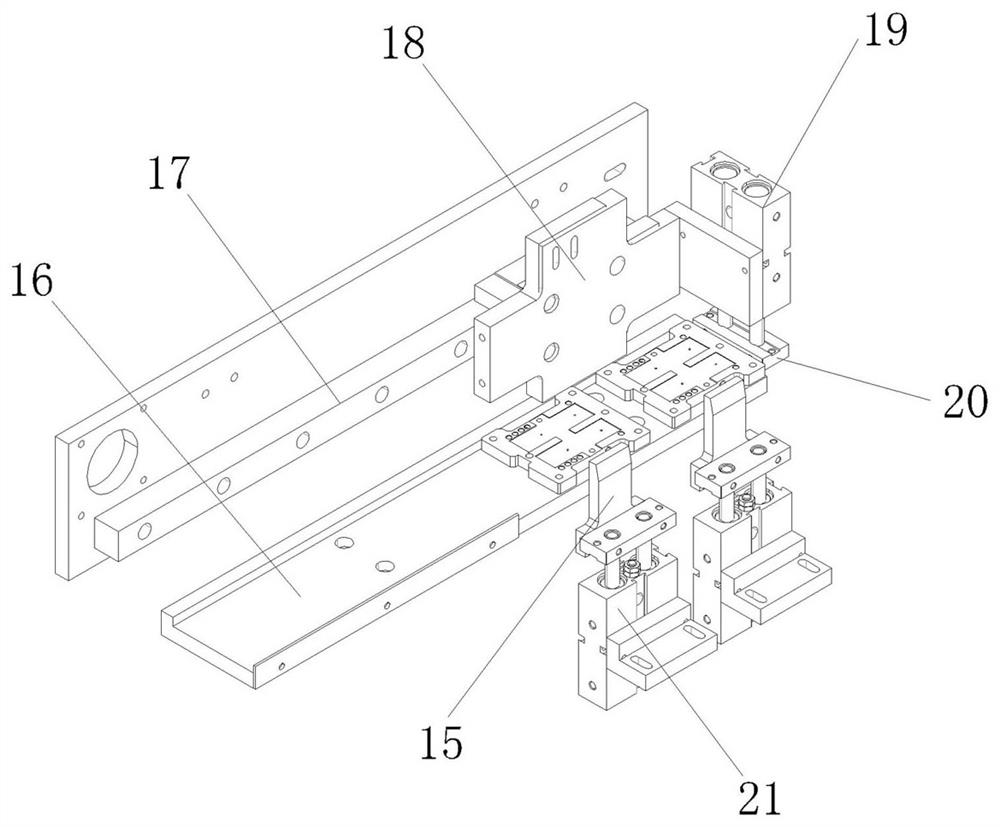

[0019] see Figure 1-2 , the present embodiment provides the following technical solutions: an automatic feeding device for Mylar sheets, including a bottom plate 1, and a feeder feeder 2 and a robot transfer mechanism 3 for feeding Mylar sheets are arranged on the upper part of the bottom plate 1 , the first feed assembly line and the second feed assembly line that are used to supply the jig and are arranged in parallel, and the handling module 4 used to push the jig to the magnet assembly equipment, and the grabbing end of the manipulator transfer mechanism 3 is provided for The suction head for absorbing the Mylar sheet is provided with a camera 5 for taking pictures of the Mylar sheet at the feeding end of the feeder feeder 2. A light source is provided at the camera 5, which can improve the effect of taking pictures. The setting of the camera 5 It can be used to accurately position the mylar sheets provided by the Feida feeder 2, and realize accurate pick-and-place materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com