Special tool for conveniently disassembling and assembling rotor assembly

A rotor and assembly technology, applied in the field of mobile vertical shaft impact crushing station, can solve the problems of affecting production efficiency, time-consuming and labor-intensive, and small working space, and achieve the effect of shortening working time, safe and reliable operation, and convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below according to the accompanying drawings and embodiments.

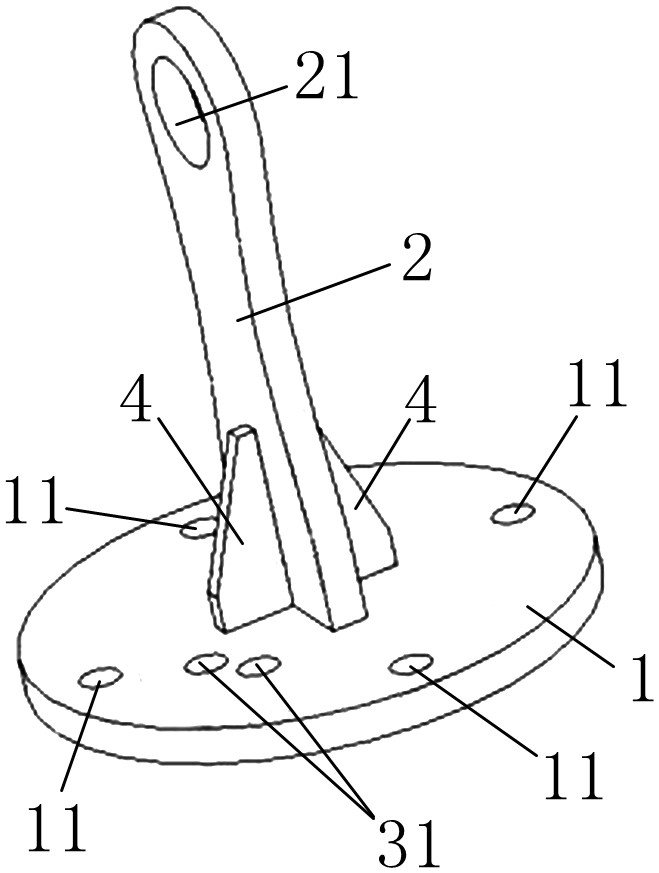

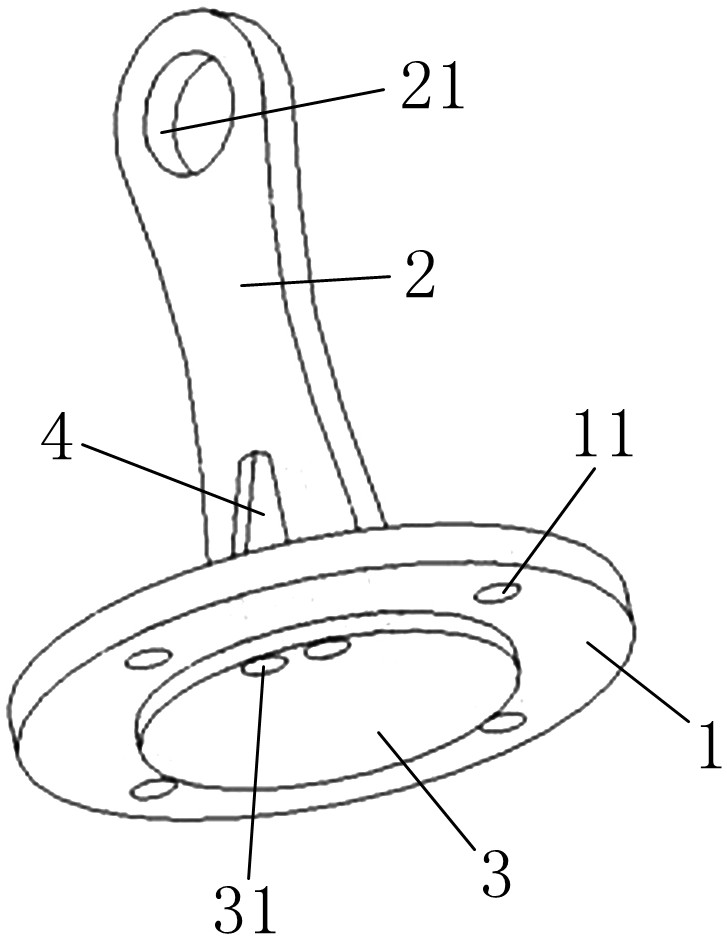

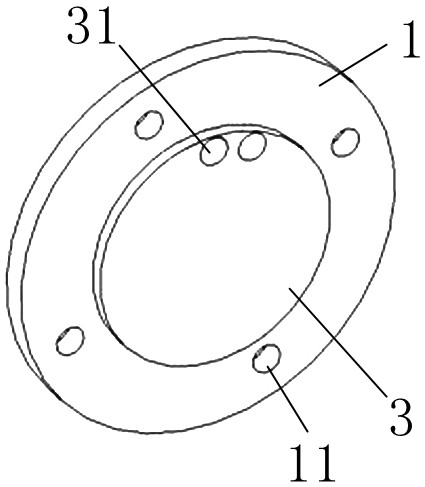

[0016] Such as Figure 1 to Figure 3 As shown, a special tool for convenient disassembly and assembly of the rotor assembly. The special tool 5 includes a pressure plate 1 and a lifting ear 2. The pressure plate 1 is a circular plate. The pressure plate 1 must have sufficient strength and rigidity. The weight of the rotor assembly is matched. One end surface of the pressure plate 1 is provided with a circular boss 3 for supporting the main shaft assembly and the taper sleeve of the rotor assembly. The axis of the circular boss 3 is coaxial with the axis of the pressure plate 1. Preferably, The pressure plate 1 and the circular boss 3 are integrally formed, and the integrated molding can be realized by the following method: during machining, the first choice is to process a circular plate, and then select one side of the circular plate to process a circular pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com