A kind of preparation technology of tangerine peel golden flower green tea with hypoglycemic effect

A production process and blood sugar-lowering technology, which is applied in tea processing before extraction, etc., can solve problems such as difficult stability of product quality characteristics, single category, and inability to fully highlight the health effects of Jinhua, so as to improve market economic benefits and lower blood sugar. , the effect of breaking through the limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

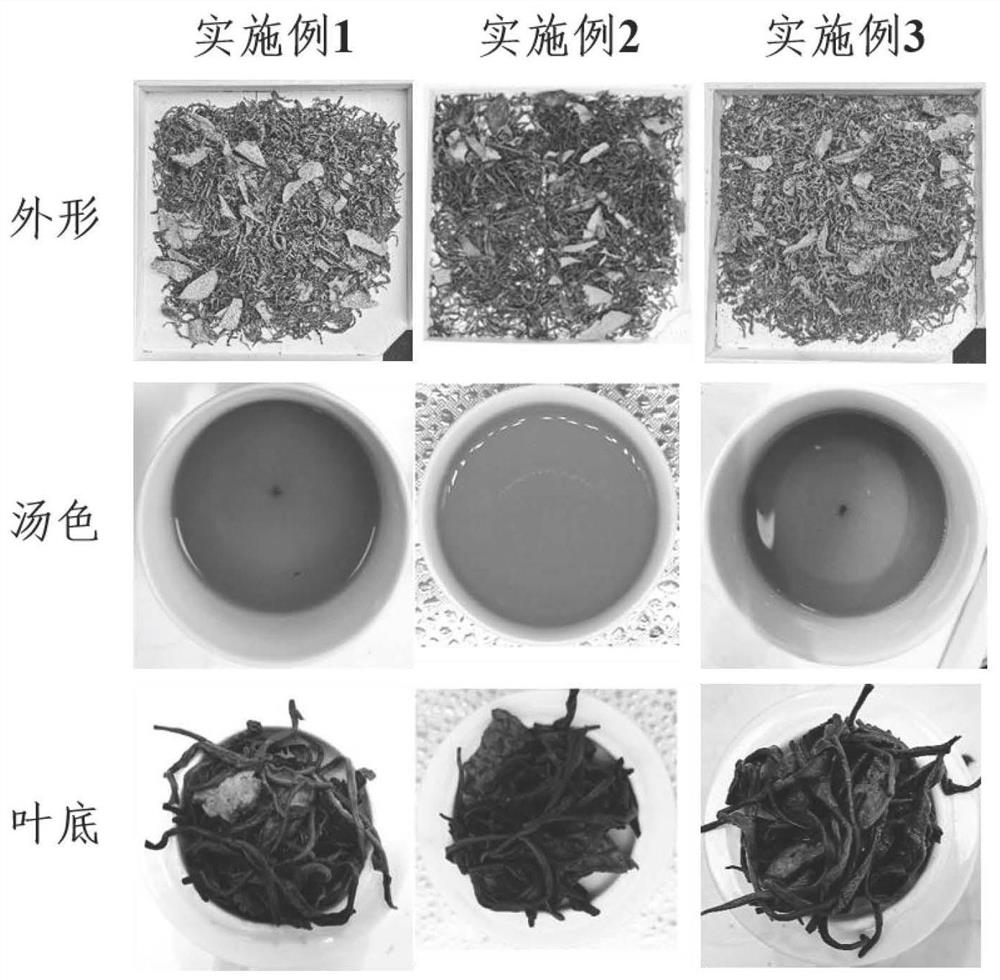

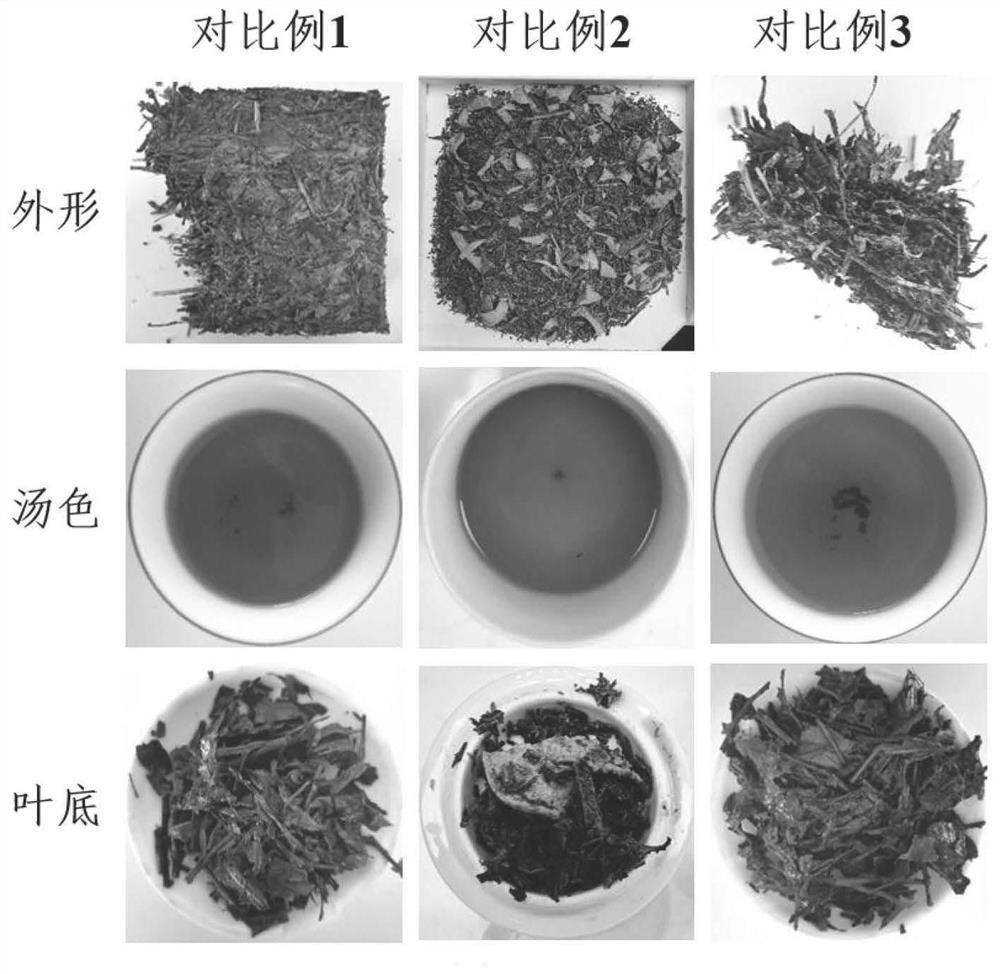

[0044] The making of embodiment 1 tangerine peel golden flower green tea

[0045] Its preparation method comprises the following steps:

[0046] (1) Production of dry green tea: pick fresh leaves of summer and autumn tea with one bud and one leaf or one bud and two leaves Yinghong No. Made green hair tea;

[0047] (2) Tangerine peel treatment: cut the 5-year-old orange peel in Xinhui, Jiangmen, Guangdong into strips with a width of 1-2cm;

[0048] (3) Steaming: mix green mao tea and tangerine peel according to the weight ratio of 10:1, and steam at 140°C for 60s;

[0049](4) Heaping: the mixed tea made of green hair tea and tangerine peel is piled for 10 hours under the condition of temperature 25°C and humidity 23%, the height of the pile is 60cm, then the humidity is adjusted to 25.5%, the temperature remains unchanged, and the transition 22h;

[0050] (5) Flowering: adjust the temperature to 30°C, adjust the humidity to 75%, and place the mixed tea in the flowering room...

Embodiment 2

[0052] The making of embodiment 2 tangerine peel golden flower green tea

[0053] Its preparation method comprises the following steps:

[0054] (1) Production of green tea dry tea: pick fresh leaves of summer and autumn tea with one bud and one leaf or one bud and two leaves Yinghong No. 9, stand green for 3 hours, finish greening at 270°C for 7 minutes, quickly spread cool for 3 minutes, knead for 45 minutes, and dry at 100°C for 1.5 hours , made green hair tea;

[0055] (2) Tangerine peel treatment: cut the 5-year-old orange peel in Xinhui, Jiangmen, Guangdong into strips with a width of 1-2cm;

[0056] (3) Steaming: mix green hair tea and tangerine peel according to the weight ratio of 14:1, and steam at 135°C for 80s;

[0057] (4) Heaping: the mixed tea made of green tea and tangerine peel is piled for 8 hours under the condition of temperature 25°C and humidity 23%, the height of the pile is 50cm, then the humidity is adjusted to 24%, the temperature remains unchanged,...

Embodiment 3

[0060] The making of embodiment 3 tangerine peel golden flower green tea

[0061] Its preparation method comprises the following steps:

[0062] (1) Green tea dry tea production: pick fresh leaves of summer and autumn tea with one bud and one leaf or one bud and two leaves Yinghong No. Made green hair tea;

[0063] (2) Tangerine peel treatment: cut the 5-year-old orange peel in Xinhui, Jiangmen, Guangdong into strips with a width of 1-2cm;

[0064] (3) Steaming: mix green mao tea and tangerine peel according to the weight ratio of 18:1, and steam at 145°C for 40s;

[0065] (4) Heaping: Put the mixed tea made of green hair tea and tangerine peel at a temperature of 25°C and a humidity of 23% for 12 hours, and the height of the heap is 70cm, then adjust the humidity to 27%, keep the temperature unchanged, and transition for 24 hours ;

[0066] (5) Flowering: adjust the temperature to 32°C, adjust the humidity to 80%, and place the mixed tea in the flowering room for 22 days;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com