Turnover type electroplating hanger

An electroplating hanger and flip-type technology, which is applied in the electrolysis process, electrolysis components, etc., can solve the problems of low work accuracy and work efficiency, poor stability, time-consuming and laborious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

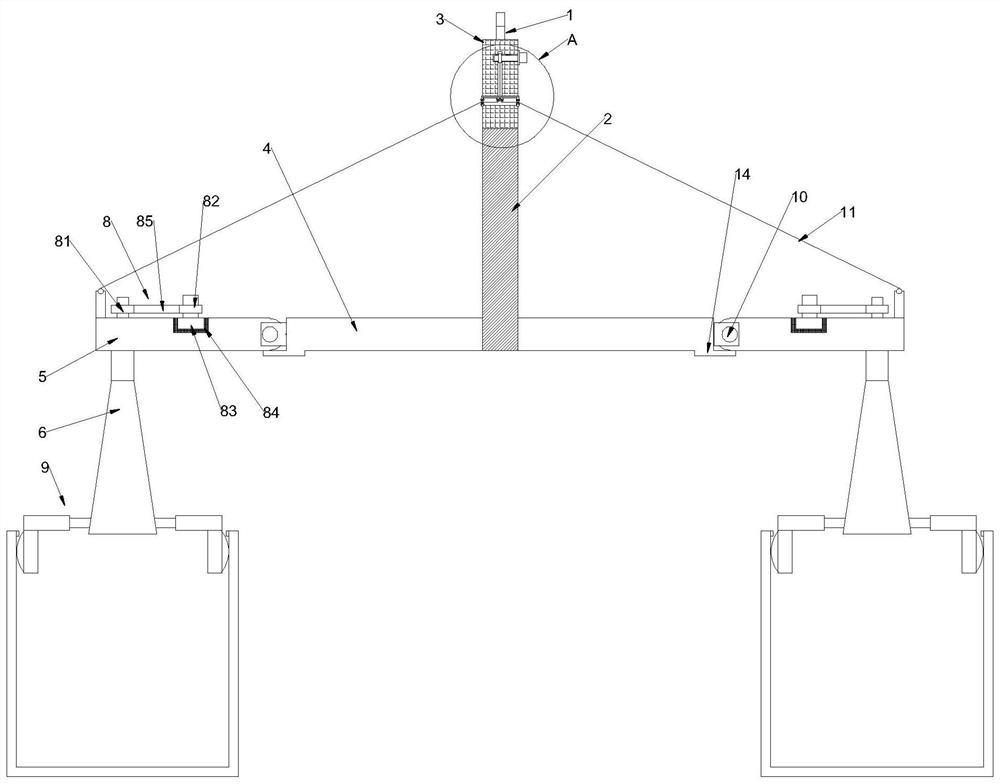

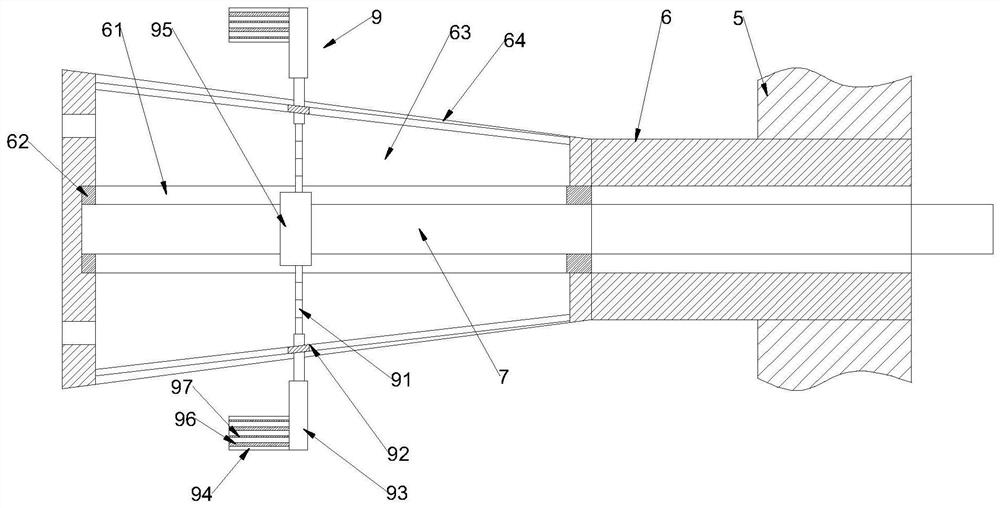

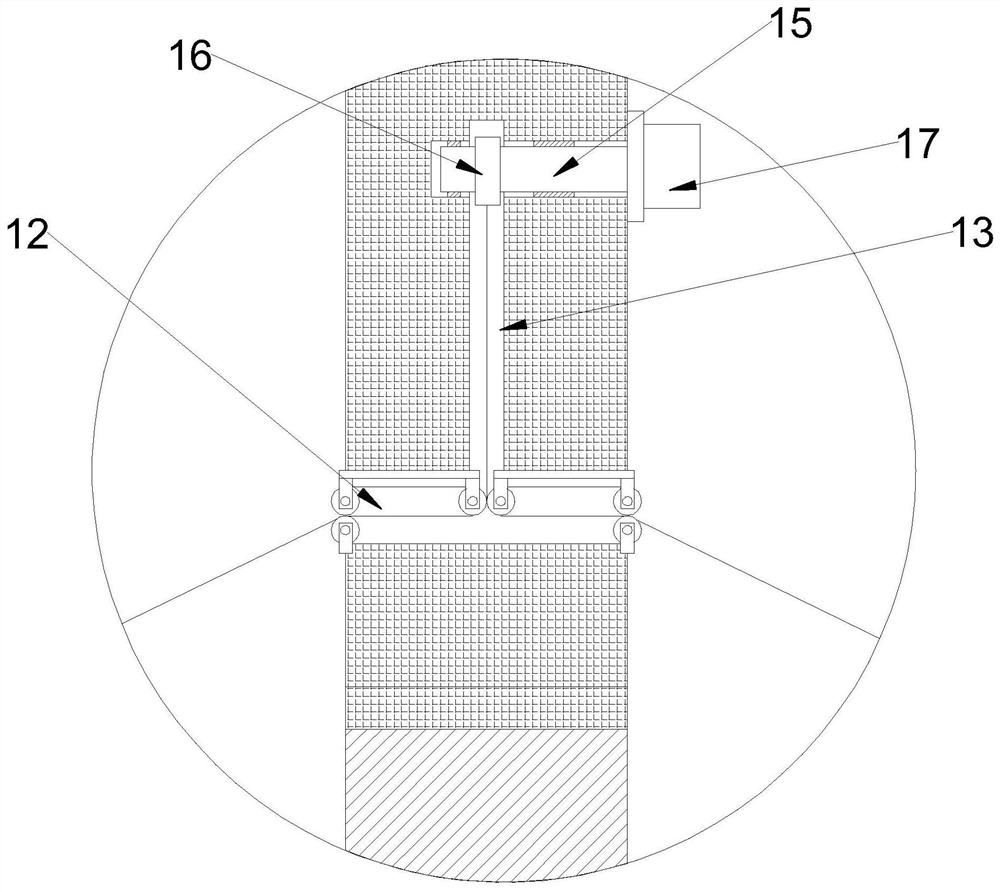

[0023] Combine Figure 1 to 3 A flip-type electroplating hangner, in the present embodiment, including hook 1, vertical rod 2, vertical extension rod 3, horizontal rod 4, transverse rod 5, and positioning group; hook 1 is fixed to vertical extension stick 3 The top end of the vertical extension rod 3 is attached to the vertical rod 2, and the horizontal rod 4 is provided with at least two groups, and uniformly surrounds the bottom end of the vertical rod 2, and the end of the horizontal rod 4 is fixedly rotated. 10 Turn connected to one end of the transverse long rod 5, and the other end of the transverse rod 5 is provided with a certain bit ring, and a pull-out rope 11 is connected within the positioning ring, and the vertical extension rod 3 is provided with a rope 11 corresponding to the cross hole 12 The central hole 13 in which the vertical extension rod 3 is in communication is provided, and the top end of the center hole 13 is attached, and one end of the drawstring 11 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com