Automatic pitting device of metal pipe drawing equipment

A drawing equipment and metal tube technology, which is applied to metal drawing forming tools, metal processing equipment, metal wire drawing, etc., can solve the problems of core head displacement, high labor intensity, and reduced production efficiency, and avoid empty drawing. And the effect of broken pipes, reducing labor intensity and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

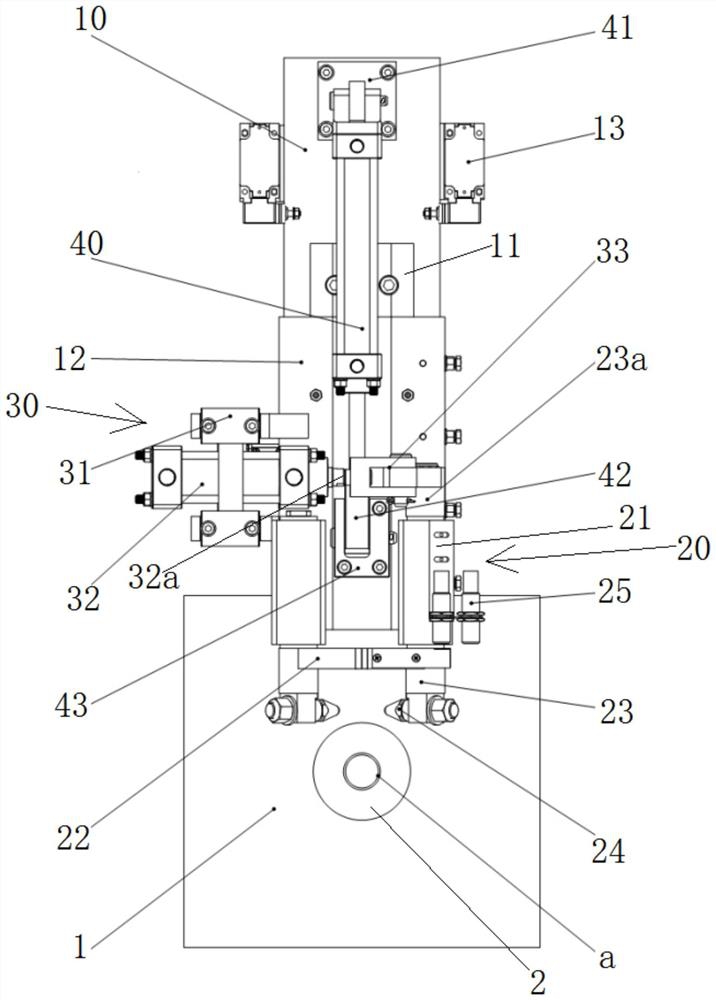

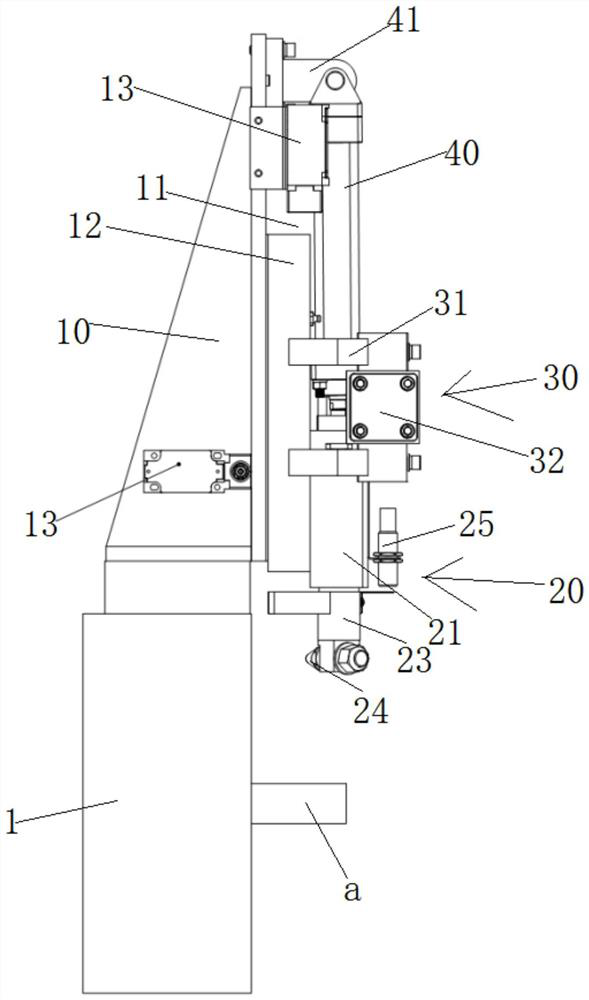

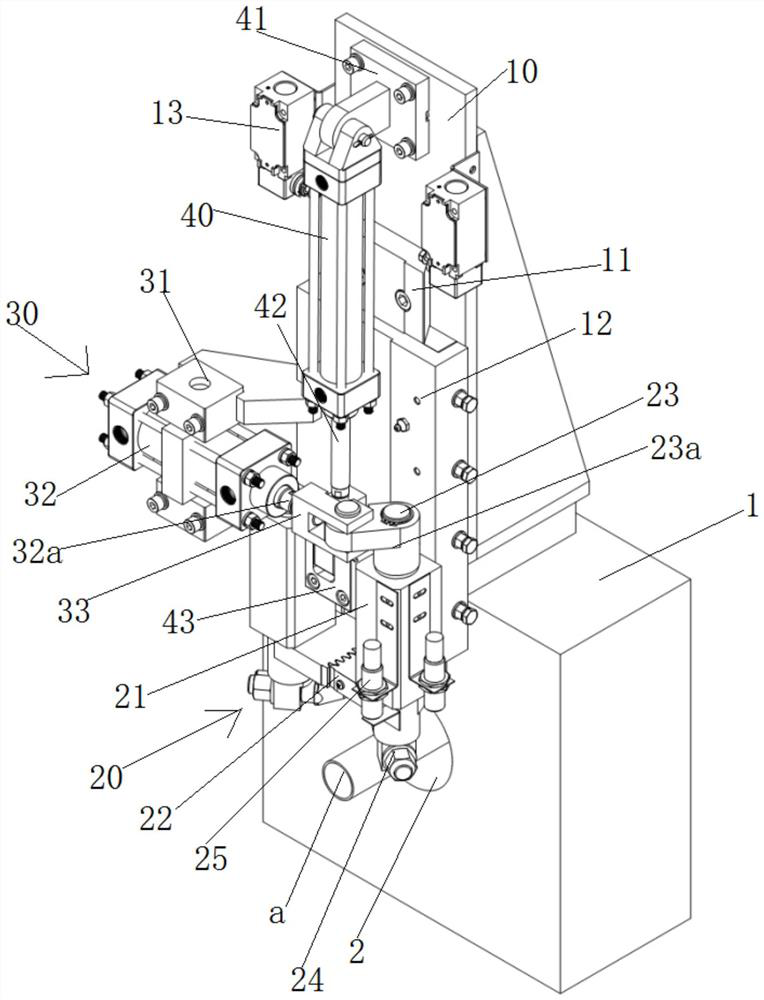

[0021] see Figure 1 to Figure 3 The shown automatic pitting device of a metal drawing equipment includes a mounting frame 10 arranged on the mold wall 1 and a pitting device 20 which is slidably arranged on the mounting frame 10 and is used to pit the metal pipe a and A hydraulic drive device 30 is slidably arranged on the installation frame 10 and used to drive the drilling device 30 to work. The mold wall 1 in this embodiment is provided with a through hole 2 matching with the metal pipe a. It is convenient to pull out the trolley to pass the metal pipe a through the through hole 2.

[0022] The hydraulic drive unit 30 is connected with the pit device 20, and the mounting frame 10 is also provided with a lifting device 40 for driving the pit device 20 to move up and down, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com