Tunable mode-locked fiber laser based on helical mechanism, preparation and output method

A technology of fiber lasers and helical mechanisms, which is applied to lasers, laser components, phonon exciters, etc., can solve the problems that the polarization controller cannot realize the quantization of output light parameters, is easily affected by the environment, and has high costs, so as to facilitate integration Advanced design, easy integration, and low environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

[0049] In view of the problems existing in the prior art, the present invention provides a tunable mode-locked fiber laser based on a helical mechanism. The present invention will be described in detail below with reference to the accompanying drawings.

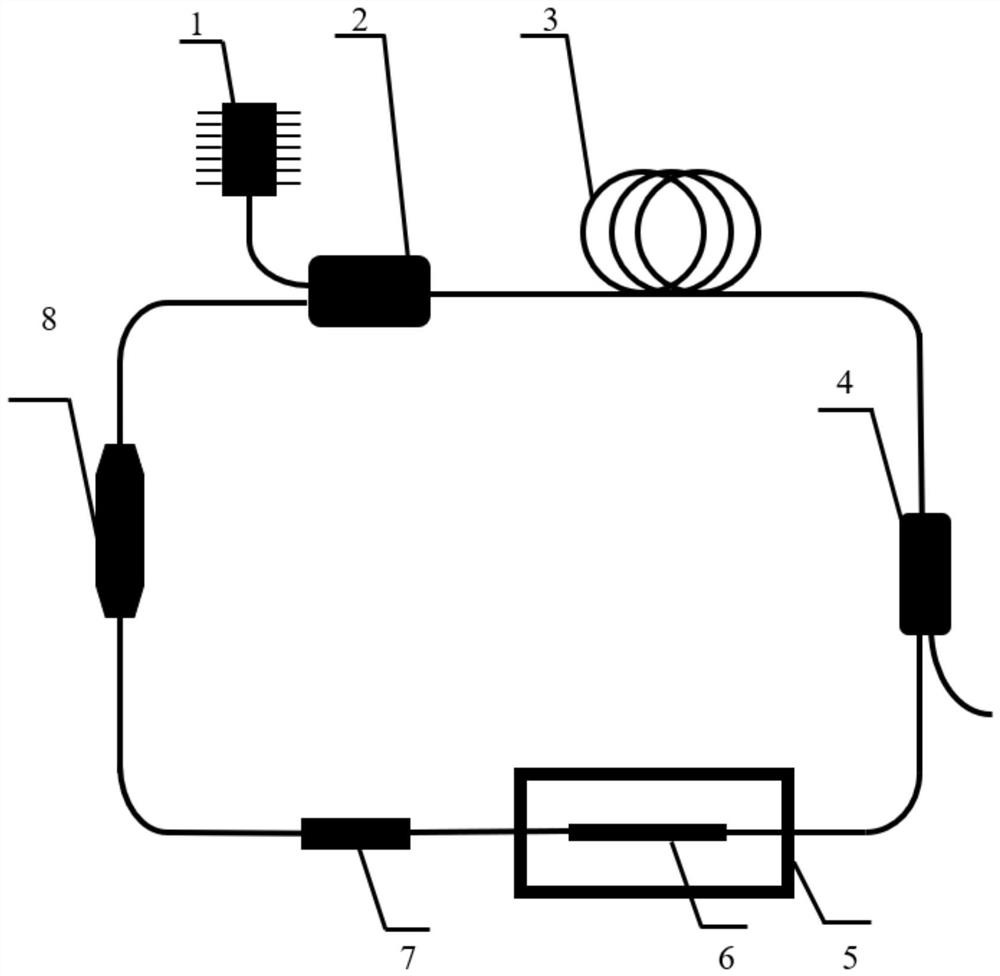

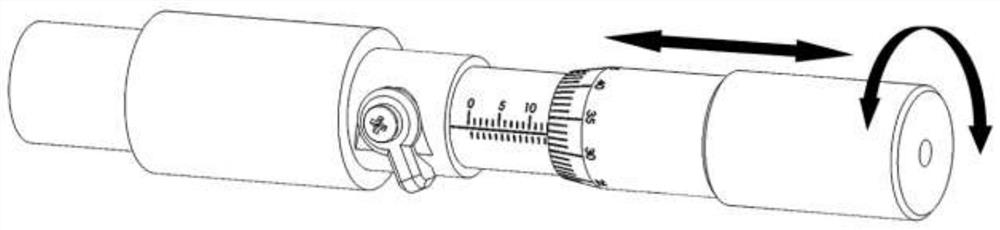

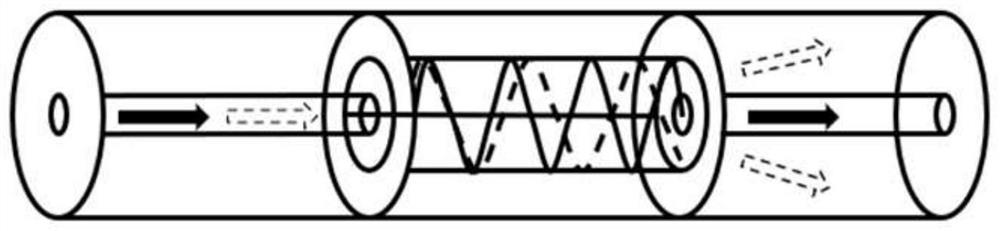

[0050] like figure 1 As shown, the tunable mode-locked fiber laser based on the helical mechanism provided by the embodiment of the present invention includes: a pump source 1, a wavelength division multiplexer 2, a gain fiber 3, an output coupler 4, a helical mechanism 5, a single-mode-multiple Mode-Single Mode (SMS) structure 6 , isolator 7 , saturable absorber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com