High-voltage electrostatic purification device and extractor hood

A purification device and high-voltage electrostatic technology, applied in the direction of oil fume removal, electrostatic separation, electrostatic effect separation, etc., can solve the problems of short ionization zone distance, weak charging capacity of oil fume particles, and reduced distance of dust collection area, etc., to improve ionization Good charging ability, oil fume purification ability, uniform distribution area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

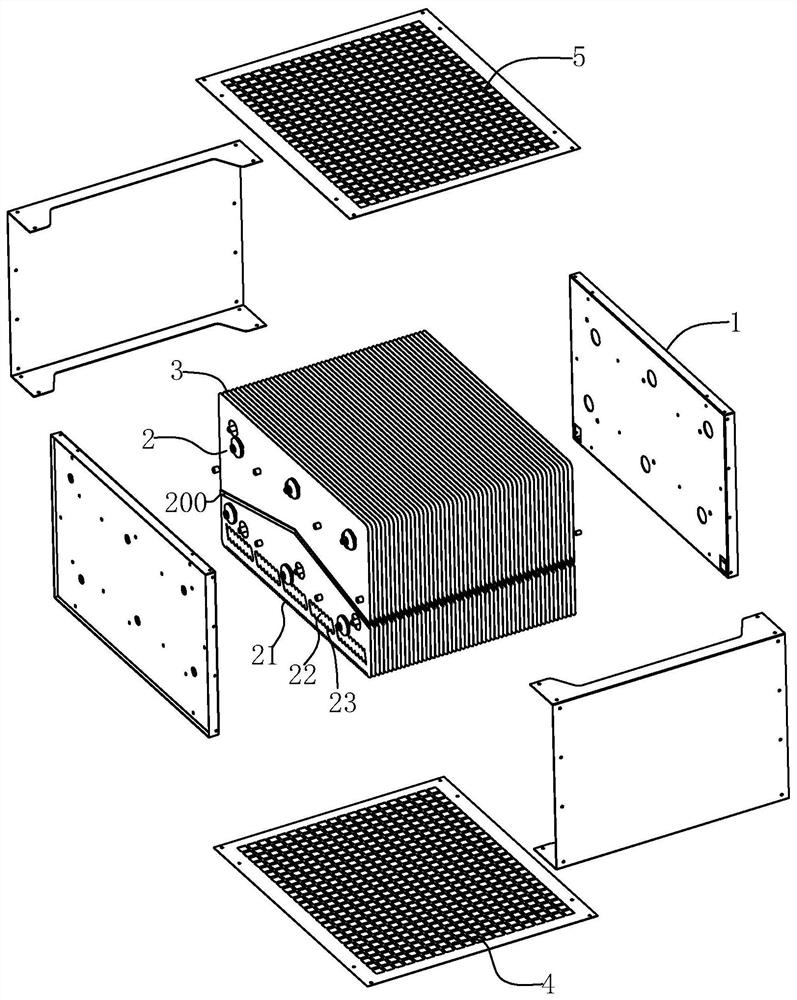

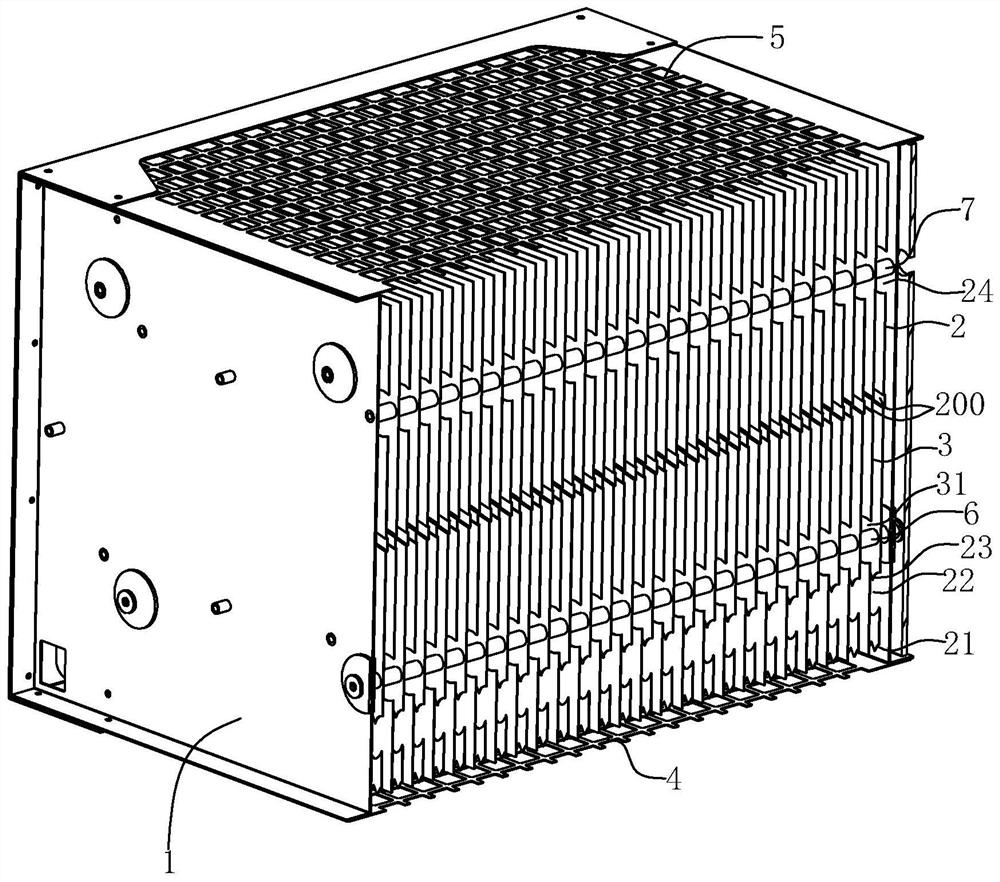

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

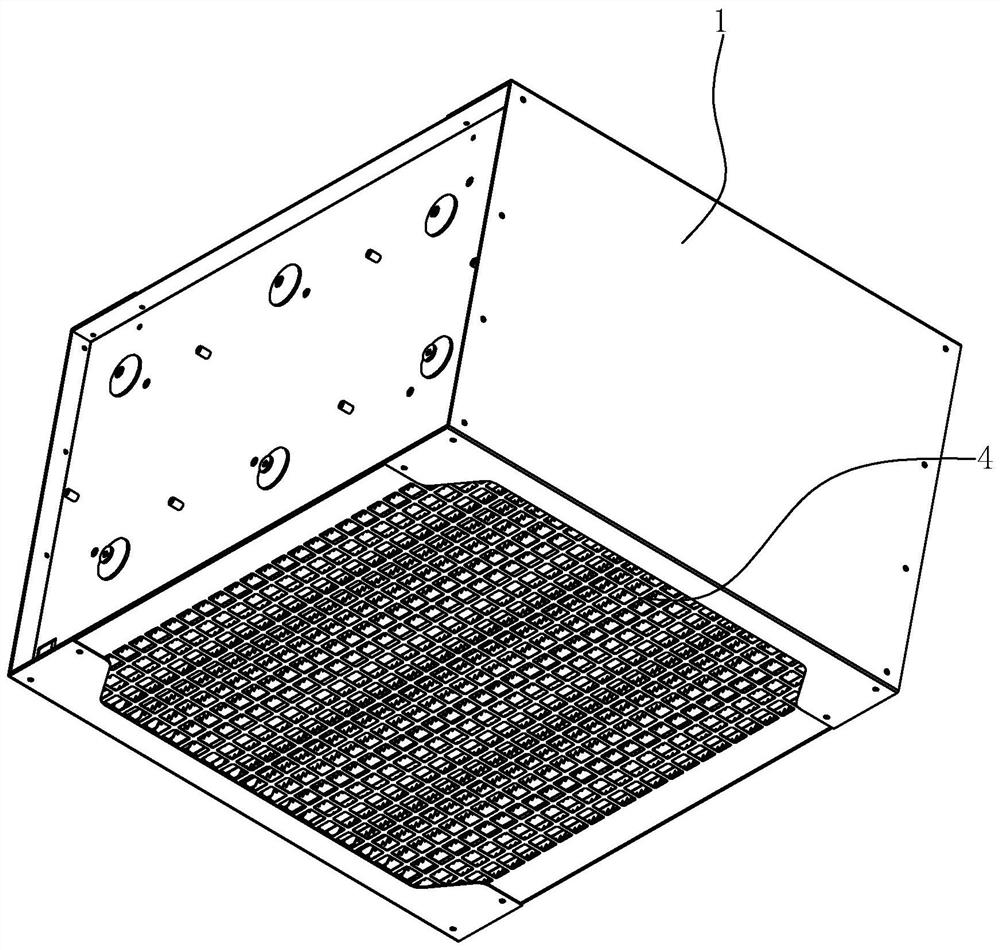

[0025] The high-voltage electrostatic purification device in this embodiment can be applied in electrical appliances such as air conditioners, air purifiers, and range hoods. In this embodiment, the range hood is taken as an example, and the high-voltage electrostatic purification device and the high-voltage electrostatic purification device are applied The range hood is described in detail.

[0026] The range hood in this embodiment includes a casing and a fan system disposed in the casing. An air outlet hood is provided at the rear end of the fan system, so that the oil fume filtered by the fan is discharged through the air outlet hood. The high-voltage electrostatic purification device can be installed at the front end of the fan system or at the rear end of the fan system as required, so as to ensure that the high-voltage electrostatic pur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com