Production method of video deep well rescue steel wire rope

A production method and wire rope technology are applied in the field of deep mine rescue wire rope production of visual information, which can solve the problems of inability to know the mine situation in real time, reduce rescue efficiency and other problems, and achieve the effect of improving efficiency and safety, high strength and ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings.

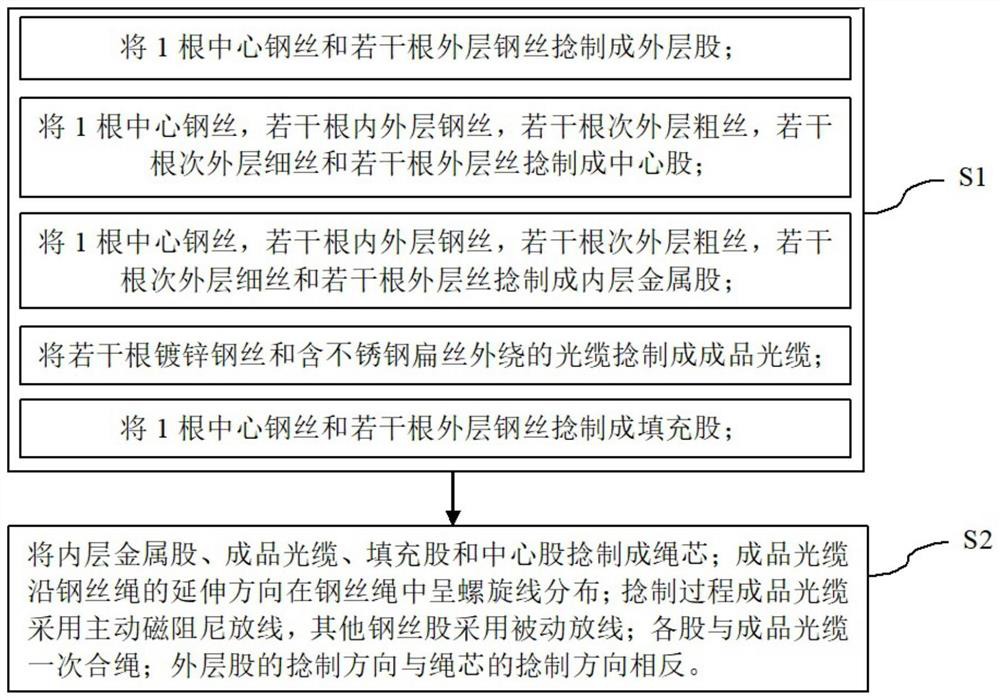

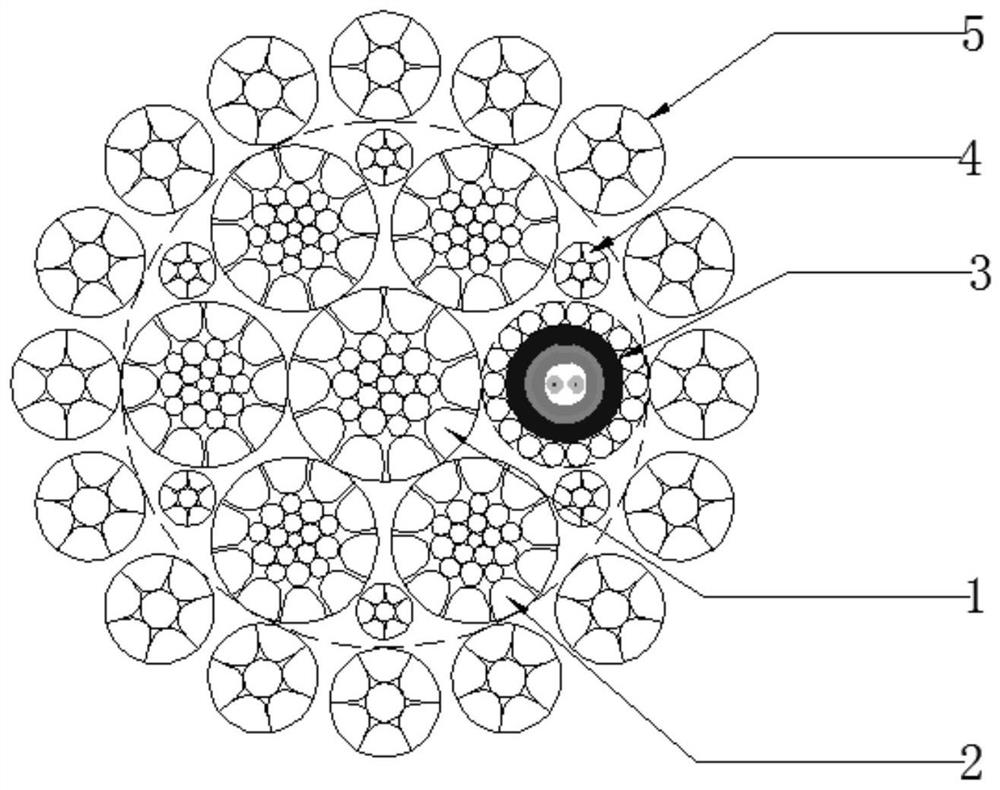

[0045] This embodiment provides a figure 1 The production method of the deep well rescue wire rope shown in the video includes:

[0046] Step one includes:

[0047] Twisting one center steel wire and several outer layer steel wires to make outer layer strands, the twist direction is left twist. In this embodiment, one center steel wire of 1.12 mm and six outer layer steel wires of 0.96 mm are twisted by a twisting machine to form an outer layer strand, the diameter of which is 2.77 mm, the lay length is 24.0 mm, and the twist direction is left twist.

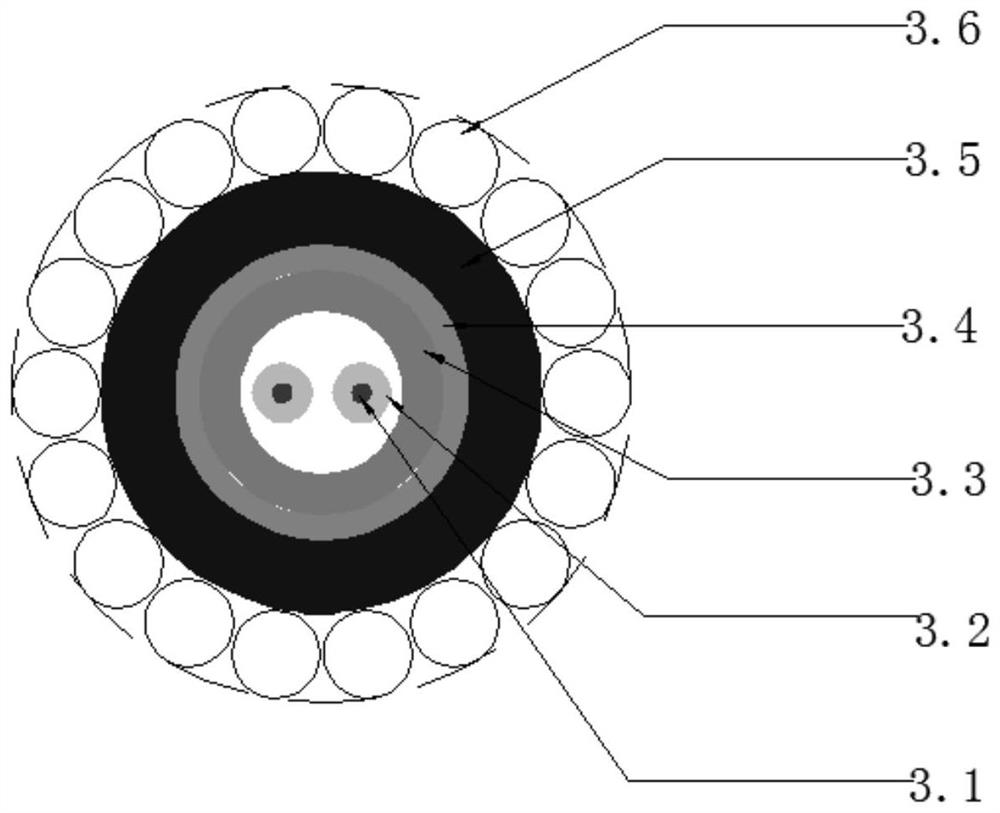

[0048] Twisting one central steel wire, several inner and outer layer steel wires, several second outer layer thick wires, several second outer layer thin wires and several outer layer wires into a central strand, the twisting direction is left twist. In this embodiment, 1 central steel wire of 0.53 mm, 5 in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com