Fluidized bed hydrogenation reaction system and hydrogenation method

A technology of hydrogenation reaction and reaction system, which is applied in hydrotreating process, petroleum industry, treatment of hydrocarbon oil, etc., can solve the problems of poor deoiling effect of waste catalyst, complicated process and high energy consumption, and achieve the effect of strengthening heavy oil desorption , The processing method is simple, and the effect of improving the processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

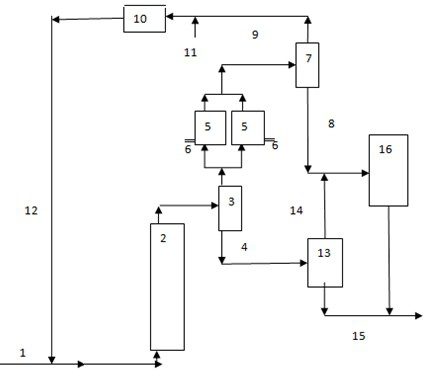

Method used

Image

Examples

Embodiment 1

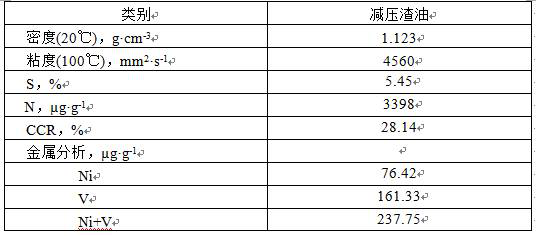

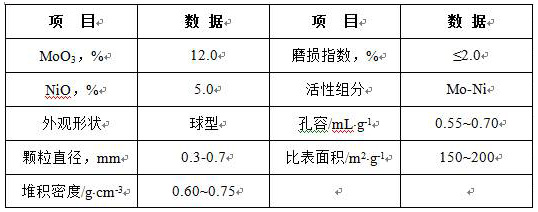

[0037] Example 1: Vacuum residual oil is used as raw material, and vacuum residual oil is mixed with fresh hydrogen into an ebullated bed reactor for hydrogenation reaction. Hydrogenation reaction conditions: reaction temperature: 420°C, reaction pressure 18MPa, volume space velocity 0.5h -1 , the volume ratio of hydrogen to oil is 800; the reaction product is separated by a hot high-pressure separator, and the separated gas phase enters the catalyst stripping tank 5 for catalyst stripping. The stripping process conditions: stripping temperature: 415°C, stripping gas phase pressure 17.5MPa, stripping After completion, the dried catalyst exits the stripping tank. The specific reaction results are shown in Table 2.

Embodiment 2

[0039] The process is the same as in Example 1, except that the ebullated bed residue hydrogenation reactor and the stripping process conditions in the corresponding catalyst stripping tank, in Example 2, the reaction temperature in the ebullated bed reactor: 430 ° C, the reaction Pressure 19MPa, volumetric space velocity 0.4h -1, the volume ratio of hydrogen to oil is 900; the reaction product is separated by a hot high-pressure separator, and the separated gas phase enters the catalyst stripping tank 5 for catalyst stripping. The stripping process conditions: stripping temperature: 425°C, stripping gas phase pressure 18.5MPa, stripping After completion, the dried catalyst exits the stripping tank. The reaction results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com