Grille cleaner

A decontamination machine and grille technology, applied in water/sewage treatment, water/sludge/sewage treatment, special treatment targets, etc., can solve problems such as poor cleaning effect and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

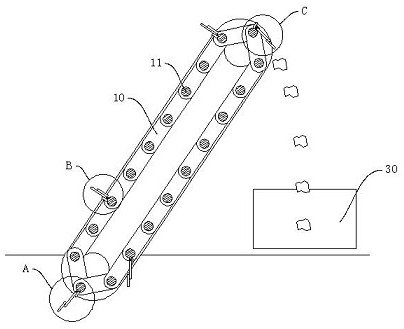

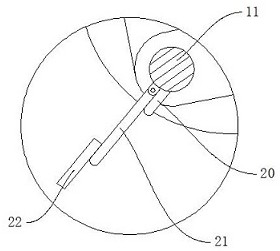

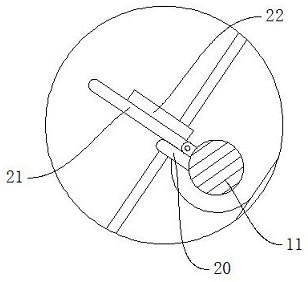

[0032] like Figure 1 to Figure 7 As shown, a grid decontamination machine provided by the embodiment of the present invention includes a decontamination machine body, the decontamination machine body includes a frame, a motor reducer, a chain, etc., and the decontamination machine body also includes a mounting shaft 11 for Rake tine is installed, this part is identical with the structure in the prior art, no longer repeats. like Figure 2 to Figure 4 As shown, the rake tooth includes a stopper 20 and a fishing tooth 21, the stopper 20 is fixedly arranged on the installation shaft 11, one end of the fishing tooth 21 is hinged to the installation shaft 11, and the fishing tooth 21 is located at the movement direction of the stopper 20 along the installation shaft 11 The rear side of the fishing tooth 21 can be turned over a certain angle towards the direction away from the stopper 20 .

[0033] When the decontamination machine is working, the motor reducer drives the chain to...

Embodiment 2

[0035] On the basis of Example 1, as Figure 5 to Figure 7 As shown, the present embodiment also includes an extended tooth 22, and a storage chute is provided on the fishing tooth 21, and a slider 221 is arranged on the elongated tooth 22, and the slider 221 is slidably arranged in the storage chute, and the slider 221 can slide along the Sliding in a direction away from or close to the installation shaft 11 , the elongated teeth 22 and the stopper 20 are located on both sides of the fishing teeth 21 .

[0036] Specifically, the storage chute has a T-shaped structure, and the slider 221 is adapted to the shape of the storage chute, such as Figure 7 As shown, a blanking hole 211 is opened through the receiving chute, and the elongated teeth 22 are shorter than the fishing teeth 21 . like Figure 2 to Figure 4 As shown, when the installation shaft 11 turns to the lower end, the extended teeth 22 slide down under the action of gravity to form a lengthened effect, and more and...

Embodiment 3

[0038] On the basis of Embodiment 1 or 2, because the garbage has a large amount of water after being salvaged from the water surface, it is all relatively troublesome in transportation and post-processing, and needs to be transferred to a dehydration device for dehydration treatment. more, it is easy to cause secondary pollution and increase the difficulty of transportation. Therefore, this embodiment also includes a dehydration device, which includes a dehydration tank 30, a driving device and a pressure device;

[0039] like Figure 8 As shown, the dehydration tank 30 includes a blanking channel 31 and a compression chamber 32, the blanking channel 31 is connected to the compression chamber 32, and the lower end of the blanking channel 31 is inclined towards the compression chamber 32, so that the garbage falls into the container under the action of gravity. Inside the compression chamber 32;

[0040] The pressure device includes a reciprocating screw 58 and a first pressi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com