Automatic tray feeding and discharging device

An automatic loading and unloading and tray technology, applied in the direction of lifting device, conveyor control device, transportation and packaging, etc., can solve the problems of low production efficiency, cumbersome, high labor costs, etc., to improve production efficiency, ensure precision, reduce equipment The effect of the failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

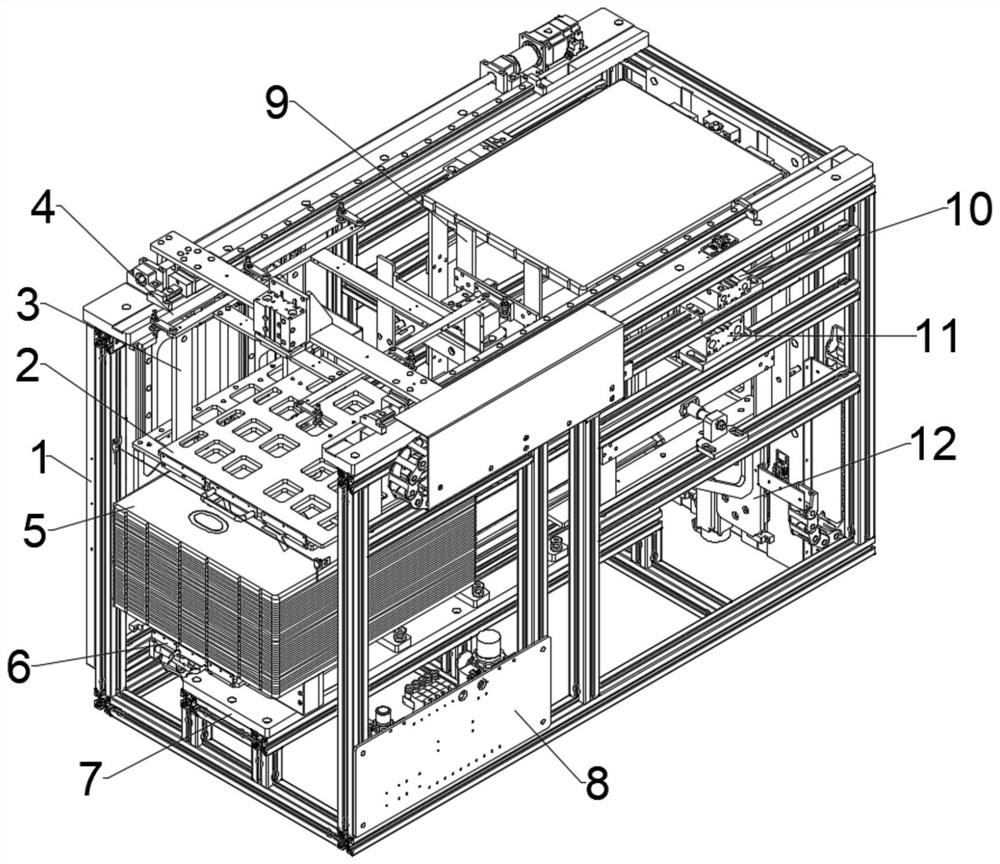

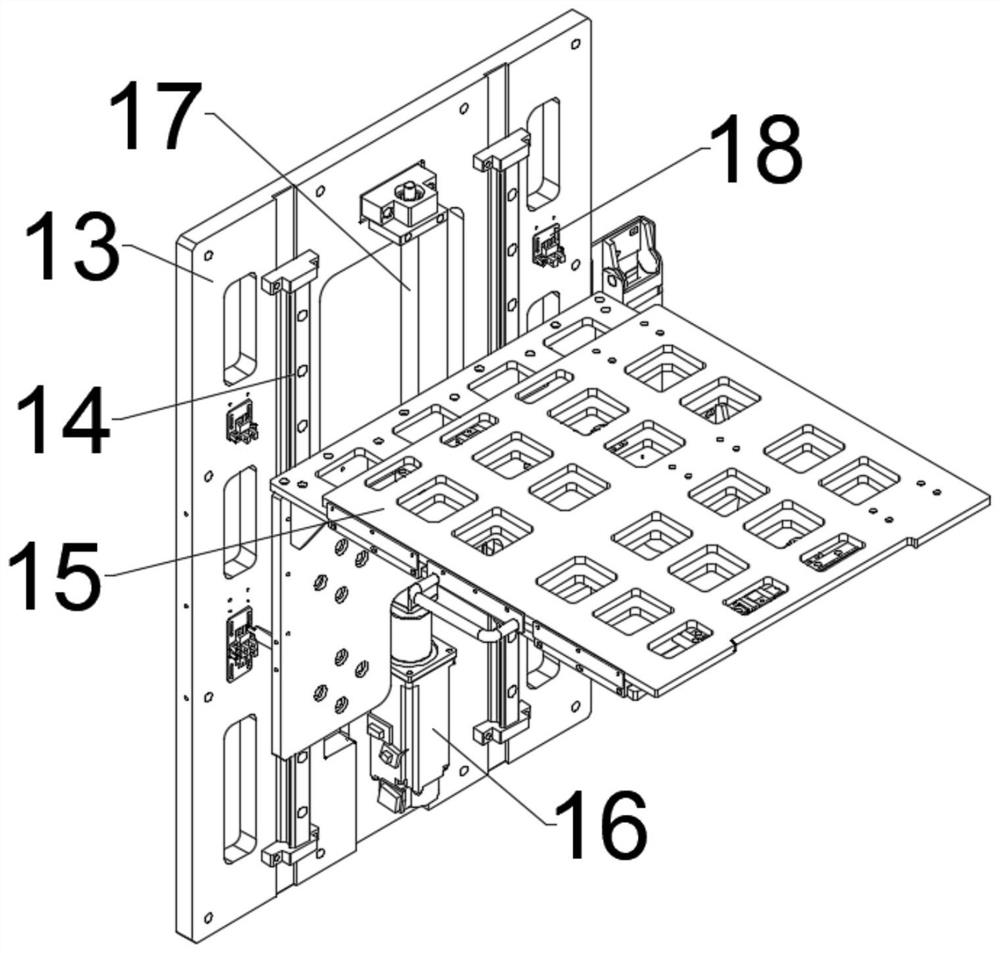

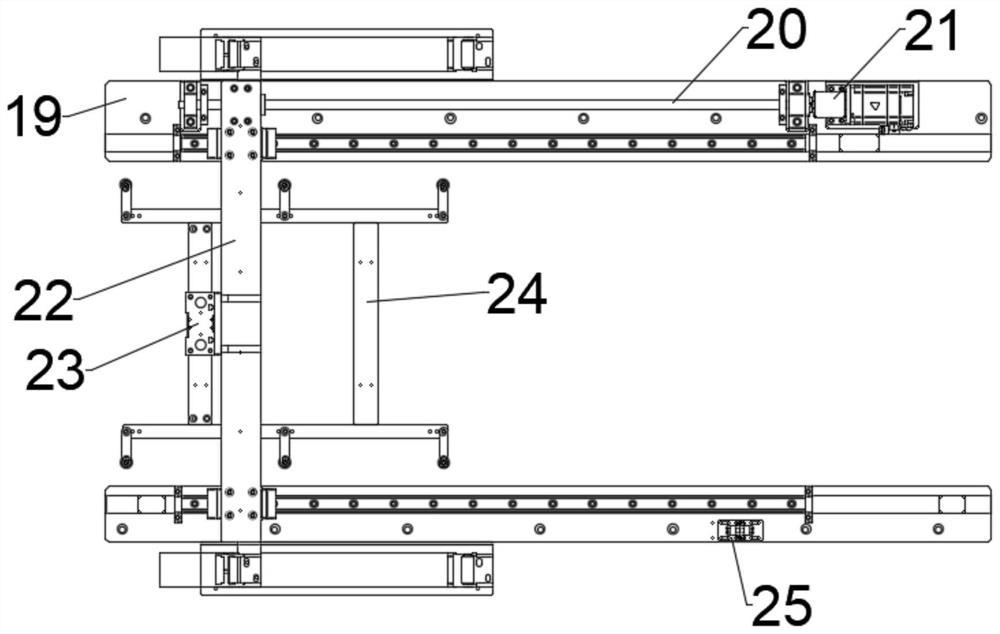

[0049] like Figure 1-Figure 12 As shown, this embodiment provides an automatic pallet loading and unloading device, including: a frame 1 , a loading assembly 2 , an unloading assembly 12 , a transfer assembly 4 and a discharge member 6 .

[0050] The feeding assembly 2 is connected to one end of the frame 1 , and the output end of the feeding assembly 2 moves up and down at one end of the frame 1 . The blanking assembly 12 is connected to the other end of the frame 1 , and the output end of the blanking assembly 12 moves up and down on the other end of the frame 1 . The transfer assembly 4 is connected to the top of the frame 1 , and the pallet 5 placed on the output end of the feeding assembly 2 is moved to the output end of the unloading assembly 12 through the transfer assembly 4 . The discharge part 6 is connected with the bottom end of the frame 1, and the tray 5 on the output end of the unloading assembly 12 is moved to one end of the frame 1 by the discharge part 6 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com