Design of full-automatic forging line robot for transferring and conveying hot forgings

A fully automated, robotic technology, applied in heating/cooling equipment, forging/pressing/hammering machinery, manufacturing tools, etc., to solve problems such as high failure rate, low conveyor belt positioning accuracy, and inflexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

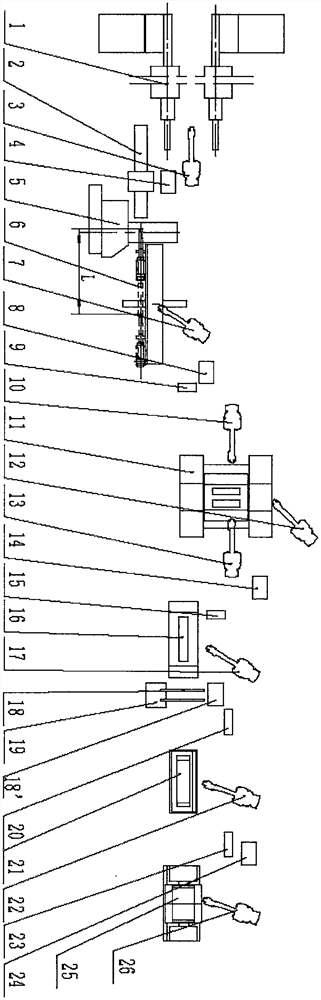

[0012] In this example figure 1 It is the general plan of the transfer and transportation of hot forgings by robots in a fully automatic forging line. The whole line includes 8 forging equipments, namely intermediate frequency furnace (1), descaling device (2), roll forging machine (5), roll forging machine operator ( 6), 10,000-ton hot die forging press (11), trimming press (16), twist press (21), calibration press (25); 8 robots, namely R1 operation robot (3), R2 operation Robot (7), R3 operation robot (10), R4 spray lubrication robot (12), R5 operation robot (13), R6 multifunctional robot (17), R7 operation robot (22), R8 operation robot (26); 4 Taichung transfer table is 1# transfer table (9), 2# transfer table (15), 3# transfer table (20) and 4# transfer table (23); the cooling pool includes R1 robot a cooling pool ( 4), R2 robot b cooling pool (8), R5 robot c cooling pool (14), R6 robot d cooling pool (18'), R7 robot e cooling pool (24).

[0013] Transfer and conveying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com