Heat dissipation device and heat dissipation method based on shape memory alloy

A memory alloy, heat sink technology, applied in cooling/ventilation/heating transformation, modification by conduction heat transfer, electrical components, etc., can solve the problems of refrigerant environmental pollution, poor heat dissipation effect of radiators, etc., and achieve high-efficiency heat The effect of transferring, improving heat dissipation efficiency and heat dissipation quality, and circulating long-term heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

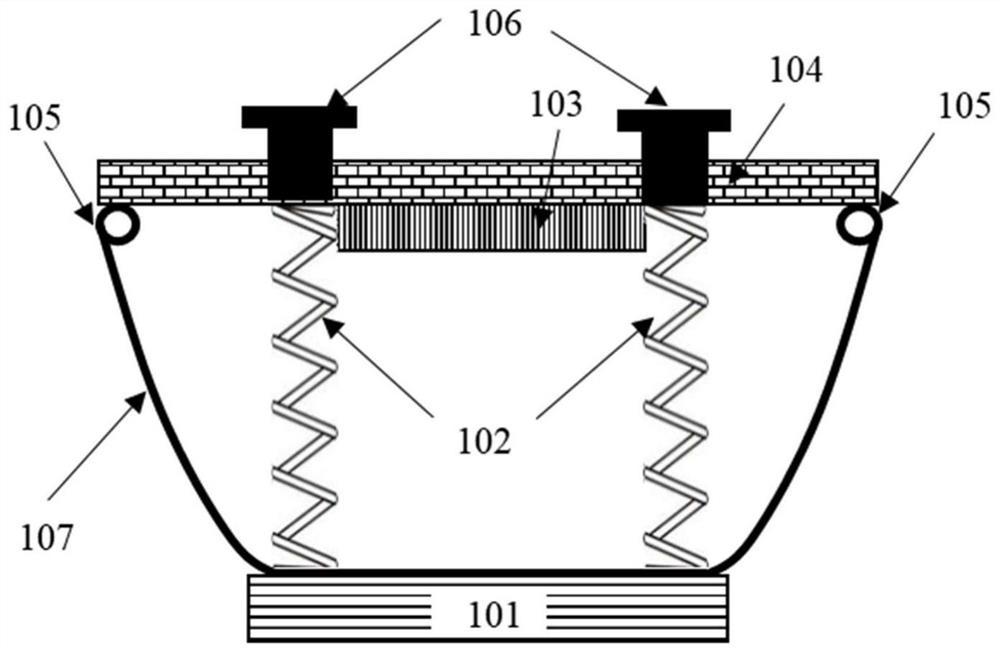

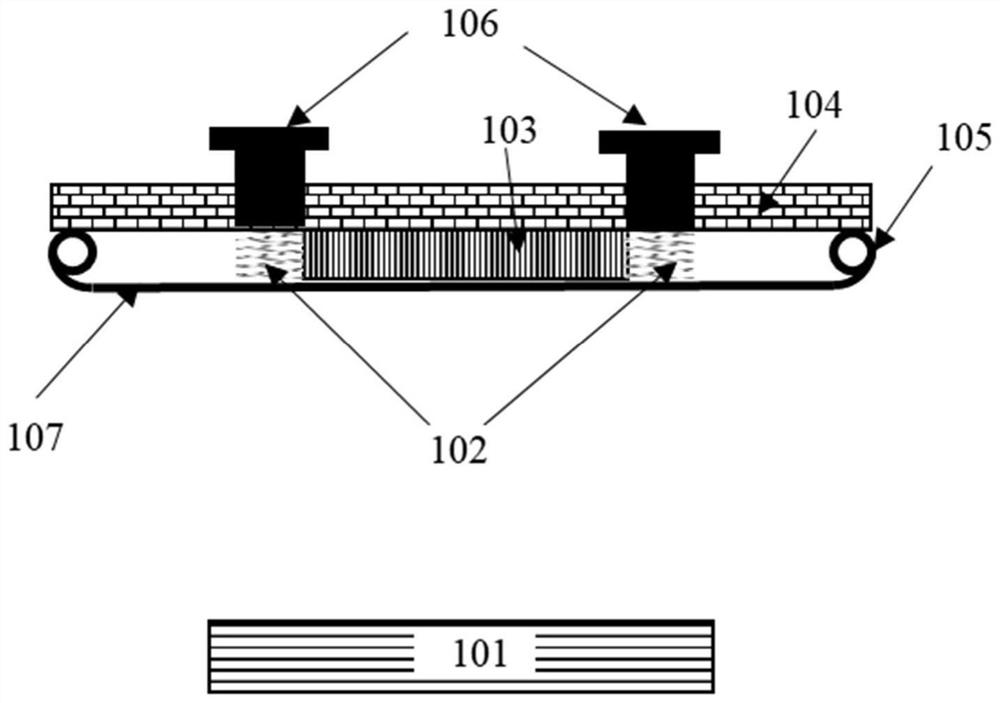

[0025] Such as figure 1 As shown, a heat dissipation device based on a shape memory alloy includes a base 104, a heat sink 103, a spring 102, and a shape memory alloy 107 are provided on one side of the base 104, and the other side surface of the base 104 penetrates the base 104 and is preloaded. device 106 , the pretensioning device 106 is connected to one end of the spring 102 , the other end of the spring 102 is connected to a shape memory alloy 107 , and the shape memory alloy 107 is fixed on the base 104 and can be supported by the spring 102 .

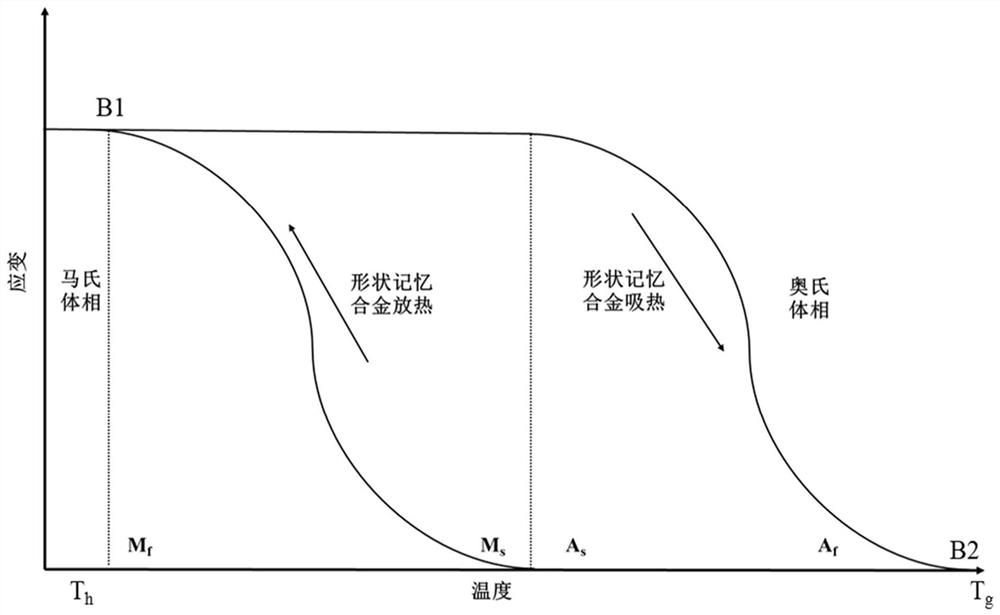

[0026] The shape memory alloy 107 in the original long state is in close contact with the heat source device 101 through the pretension force provided by the spring 102. The original length of the shape memory alloy 107 is adjusted and fixed by the clamp 105 fixed on the base 104. The pretension ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com