Hybrid magnetic flux composite structure disc type motor

A composite structure, disc motor technology, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit, electric components, etc., can solve the problems of low ratio of converted energy to volume and weight, low energy conversion efficiency of disc motors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

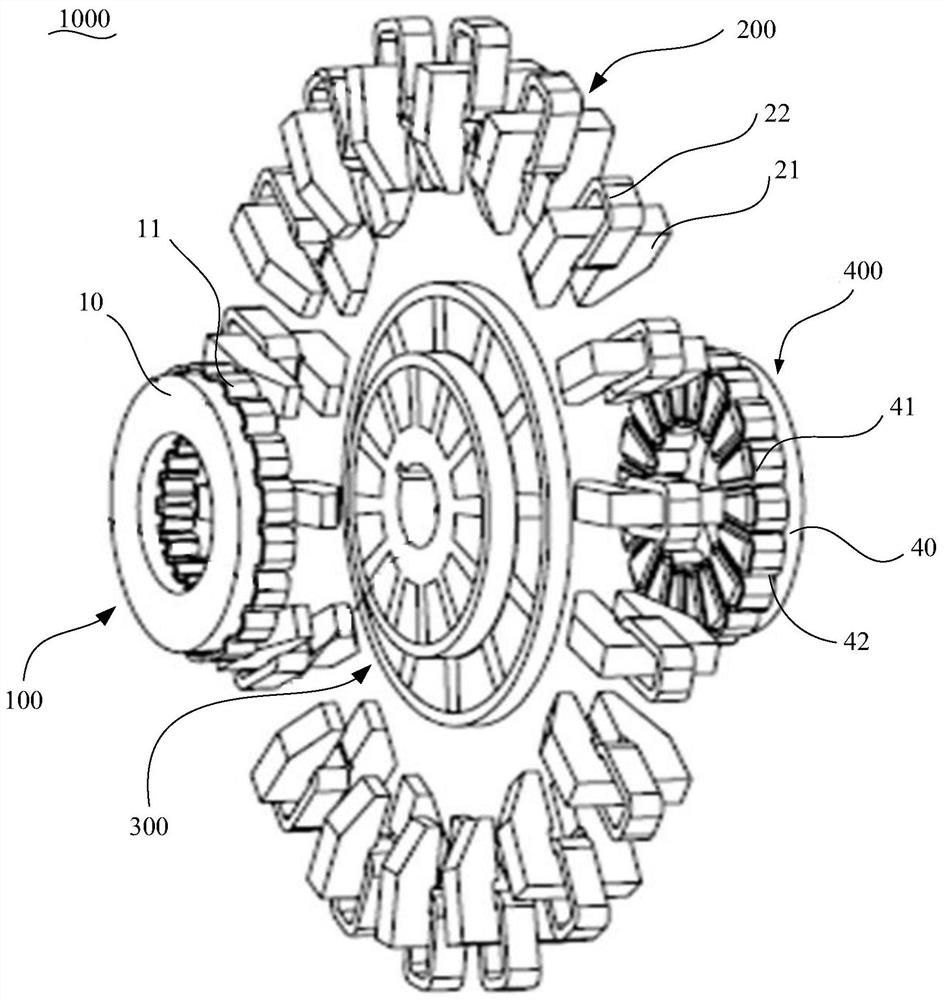

[0074] Such as figure 1 As shown, the present invention provides a hybrid flux composite structure disc motor 1000 , wherein the hybrid flux composite structure disc motor 1000 includes a front stator assembly 100 , a middle stator assembly 200 and a rotor assembly 300 .

[0075] Such as figure 2 As shown, the rotor assembly 300 includes a magnetically permeable rotor bracket 30, a front end permanent magnet 31 and an intermediate permanent magnet 32, the front end permanent magnet 31 and the intermediate permanent magnet 32 are installed on the magnetically permeable rotor bracket 30, and the intermediate permanent magnet 32 surrounds A permanent magnet 31 is provided on the front end. Specifically, the number of the front end permanent magnets 31 and the middle permanent magnets 32 are multiple, and the front end permanent magnets 31 and the middle permanent magnets 32 are uniformly distributed on the magnetic permeable rotor support 30 along the circumferential direct...

Embodiment 2

[0081] In the second embodiment provided by the present invention, the structure of the hybrid flux composite structure disc motor 1000 in this embodiment is similar to that of the hybrid flux composite structure disc motor 1000 in the first embodiment, and the similarities are not discussed. Again, just the differences.

[0082] In this embodiment, the present invention specifically discloses that the hybrid magnetic flux composite structure disc motor 1000 also includes a rear stator assembly 400, and the rotor assembly 300 also includes a rear end permanent magnet 33, and the rear end permanent magnet 33 is installed on the magnetically permeable rotor bracket 30 and set back to back with the front permanent magnet 31, the rear stator assembly 400 and the rear permanent magnet 33 face to face, that is, the rear stator core 40 of the rear stator assembly 400 faces the rear permanent magnet 33.

[0083] Further, the present invention discloses that the magnetic permeable roto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com