Motor, compressor and refrigeration equipment

A compressor and stator technology, applied in the field of refrigeration equipment, can solve the problems affecting the service life of the motor, periodic vibration, large electromagnetic noise, etc., and achieve the effects of suppressing electromagnetic noise, optimizing noise, and reducing resonance response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

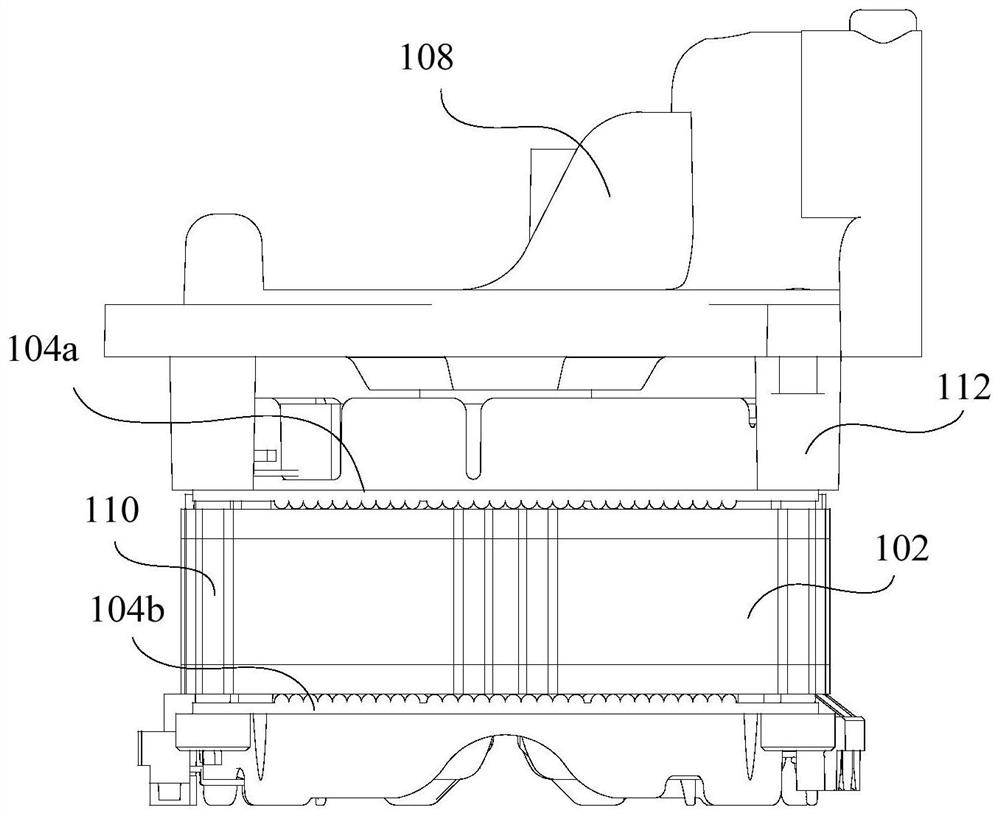

[0049] Such as figure 1As shown, the first embodiment of the present invention proposes a motor, including: a stator 102, a locking device 104, a rotor and a crankshaft.

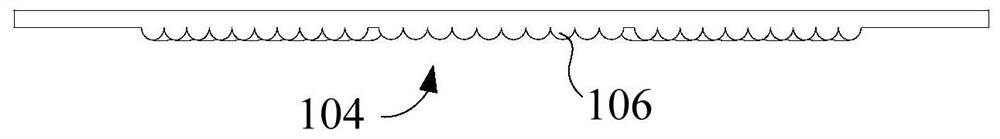

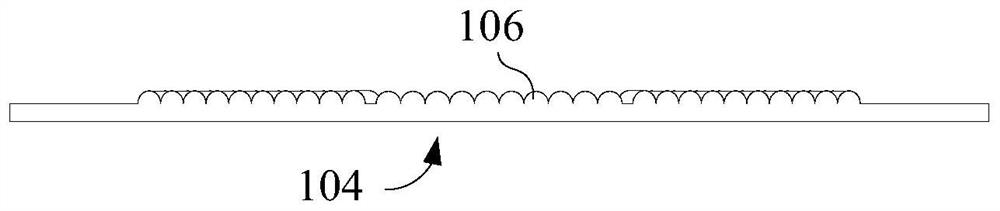

[0050] Among them, such as figure 2 and image 3 As shown, the locking device 104 is provided with a protruding structure 106, and the locking device 104 is configured to abut against the axial end surface of the stator 102 through the protruding structure 106; the rotor at least partially extends into the interior of the stator, and can It rotates under the drive of the stator; the crankshaft is connected with the rotor and can rotate under the drive of the rotor.

[0051] That is to say, during the working process of the motor proposed in this embodiment, the locking device 104 can apply pressure toward the axial end surface of the stator 102 through the protruding structure 106, which can avoid the radial deformation of the stator 102 during the working process, thereby effectively reducing the The re...

Embodiment 2

[0054] Such as figure 1 As shown, the second embodiment of the present invention proposes a motor, including: a stator 102, a first locking device 104a and a second locking device 104b.

[0055] Among them, such as figure 1 , figure 2 and image 3 As shown, the first locking device 104a and the second locking device 104b are both provided with a protruding structure 106, and the first locking device 104a is configured to abut against the upper axial end surface of the stator 102 through the protruding structure 106 , the second locking device 104b is configured to abut against the lower axial end surface of the stator 102 through the protruding structure 106 .

[0056] That is to say, during the working process of the motor proposed in this embodiment, the first locking device 104a and the second locking device 104b abut against the two axial end faces of the stator 102 from above and below the stator 102 respectively, from The upper and lower directions of the stator 102...

Embodiment 3

[0061] Such as figure 1 As shown, the third embodiment of the present invention proposes a motor, including: a stator 102 and a locking device 104 .

[0062] Wherein, the stator 102 includes a stator punching sheet, and a plurality of stator punching sheets are stacked and distributed along the axial direction of the stator 102; as figure 2 and image 3 As shown, the locking device 104 is provided with a protruding structure 106 , and the locking device 104 is configured to abut against the stator punching plate at the end through the protruding structure 106 .

[0063] The protruding structure 106 of the locking device 104 abuts against the stator punching sheet at the end, and the protruding structure 106 presses the stator punching sheet at the end under the trend of external force, making the stator punching sheets more compact and avoiding the stator punching sheet The relative movement between them, thereby avoiding the radial deformation of the stator 102, avoiding t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com